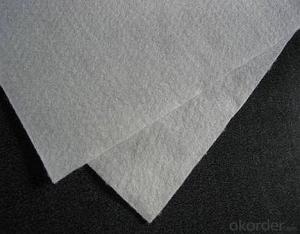

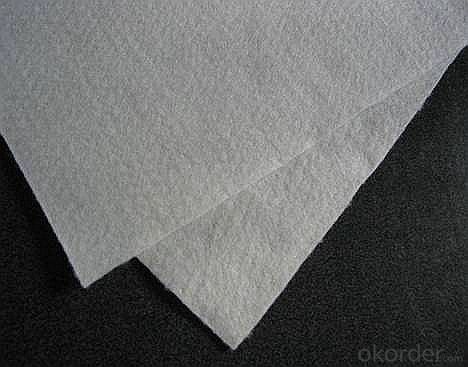

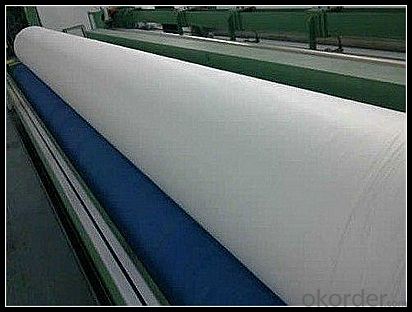

Geotextile Cloth Nz - High Stabilization and Performance Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextiles

These geotextile filter fabric materials prevent the migration of fine soils to the spaces between rock particles. The migration of fine soil into your gabion structure can cause subsidence problems below or behind the gabion structure in time if not applied correctly and will stir up problems – especially in sandy soils. Clay soils do not generally require a geotextile filter fabric as they seldom leach through the basket section. We recommend using a suitable geotextile where the gabion is in contact with earth, this will limit any movement of soils through a gabion structure. In soft soil foundations especially and wherever overlaps or joins are required, we suggest a minimum overlap of 300mm(1 ft).

Benefits

High soil confinement for greater load distribution

Durable and superior damage resistant

High modulus, for immediate structural support

Unique weave optimizing both strength and filtration properties

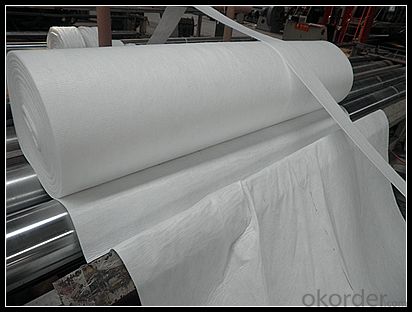

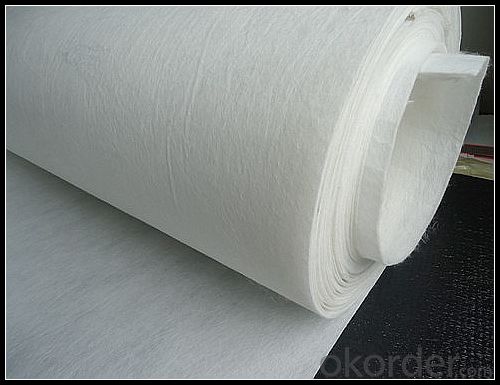

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to abrasion?

- Yes, geotextiles are generally resistant to abrasion. They are designed to withstand rubbing, friction, and wear caused by external forces, making them highly durable and suitable for various applications that involve exposure to abrasive forces.

- Q: Geotextile manufacturers rely on what to do a hundred years do not rot geotextile

- Because geotextile raw materials are chemical fiber. Huazhi geotextile material answer

- Q: Pvc waterproof board and geotextile must be used with what

- Since the waterproof board is used for waterproofing, afraid to be punctured, and geotextile with the use of the soil and the waterproof board is set between a protective layer, so most of the waterproof board should be used with geotextile. However, if the soil clean up, no sharp foreign body, but also consider not set geotextile.

- Q: Are high geotextiles harmful to people?

- High-tech geotextile is not harmful to people. High-iron geotextile for strong, tensile, anti-friction coefficient, anti-oxidation time and other indicators are very strict, it can be said that geotextile applications so far the highest requirements. The raw materials for the production of geotextile are polypropylene fiber, polypropylene fiber civilian use: can be pure or wool, cotton or viscose blended mixed woven to produce a variety of clothing. Can be used for weaving all kinds of knitwear such as socks, gloves, sweaters, knitted pants, dish cloth, mosquito cloth, was expo, warm filler, diaper wet. Industrial use: geotextile, industrial filter cloth, carpet, fishing nets, canvas, hose, concrete reinforced materials, industrial fabrics, nonwovens and so on. So do not worry, high-speed rail geotextile with environmental requirements, no harm to the human body.

- Q: Is the polyester nonwoven fabric geotextile?

- Not geotextile. Polyester non-woven fabrics: mainly used for construction, roof waterproof as a base cloth, attached to the above sand, cement, etc., to prevent the role of sand leakage. Nonwovens are often used in construction and are a measure to prevent cracks. Geotextile manufacturers, for your answer

- Q: How do geotextiles help in vegetation establishment?

- Geotextiles help in vegetation establishment by providing a stable and favorable environment for plant growth. They help to retain moisture in the soil, prevent erosion, and control weed growth. Additionally, geotextiles also protect the roots of plants from external damage and provide thermal insulation.

- Q: Where to sell geotextiles

- Those who produce geotextile manufacturers are selling black geotextile. Black geotextile according to the use of a lot of specifications, the price difference is very large. The weight per square meter between about 50-1000g grams, the weight of different unit price is different, the inquiry directly asked how much money per ton. According to the use of distinction between the current market price per ton price between 5,000 yuan - yuan. For the conservation, isolation, insulation of the geotextile the cheapest. In the 5000 yuan / ton between. For the filter, soft base treatment, slope protection, reinforced decoration, and other purposes of the black geotextile most expensive in - yuan / ton. The same black color, but different uses, production processes and production costs are not the same.

- Q: How do geotextiles contribute to the performance of geocell systems?

- Geotextiles play a crucial role in enhancing the performance of geocell systems by providing reinforcement, separation, and filtration functions. They help distribute and transfer loads evenly across the geocell structure, enhancing its stability and load-bearing capacity. Geotextiles also prevent the mixing of different soil layers, ensuring proper confinement within the geocells. Additionally, they act as a filter, allowing water to drain while preventing the migration of fine particles that could clog the system. Overall, geotextiles significantly contribute to the overall performance and longevity of geocell systems.

- Q: How do geotextiles aid in the reduction of soil compaction?

- Geotextiles aid in the reduction of soil compaction by providing a barrier between the soil and external loads, distributing the load more evenly and reducing the pressure on the soil. This allows the soil to retain its natural structure and porosity, thereby minimizing compaction and preserving its ability to absorb and drain water effectively.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by providing a barrier that separates soil layers and prevents them from being washed away by water or wind. They stabilize the soil, promote vegetation growth, and enhance drainage, ultimately reducing erosion and maintaining the integrity of the landscape.

Send your message to us

Geotextile Cloth Nz - High Stabilization and Performance Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords