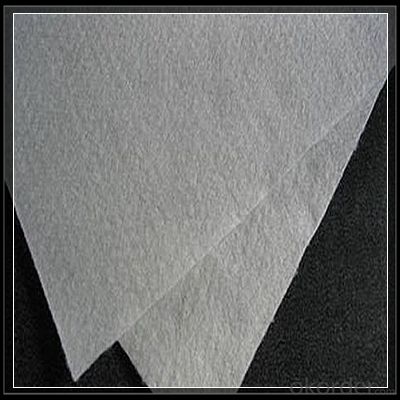

Geotextil Grk Polypropylene (PP) Geotextiles Industrial Nonwoven Fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Polypropylene (PP) Geotextiles

Polypropylene (PP) Geotextiles is a 100% polypropylene staple fibers needle formed, and its irregular weave mesh random to form a high strength fabric and the size of a balanced and stable. Polypropylene fiber manufactured according to special formula to resist ultraviolet rays. Encountered in the soil of ordinary non-active chemicals. Such fibers do not corrode or mildew, biologically non-degradable and resistant to insect or rodent damage. Polypropylene pH values 2-13 within the framework of the stability of。In addition, it lists the physical fit for the next performance parameters.

1: UV 500 hours after reservation 70% of

2: Tensile Strength / (KN / M) ≥ 7.5

3: elongation ≥ /% 45

4: Weight :120-140G per square meter

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Nonwovens is a major category of textiles, geotechnical construction is its use on the one hand, in this field people call it geotextile. Many types of non-woven fabrics, the specific technical indicators to be determined according to the actual species. Generally measure its raw materials, weight, moisture permeability, tear strength, bursting strong, etc., insulation, moisturizing. Scope: ⒈ water conservancy project dam and slope protection of the filter, channel isolation, anti-seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control. ⒌ polyester long fiber anti-sticking acupuncture geotextile has been applied throughout the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: How do geotextiles prevent soil erosion?

- Geotextiles prevent soil erosion by acting as a barrier that stabilizes the soil, allowing water to pass through while preventing the movement of soil particles. They provide reinforcement to the soil, reducing the erosive forces of wind and water, and promoting vegetation growth by retaining moisture and nutrients in the soil.

- Q: What are the challenges associated with geotextile installation?

- One of the main challenges associated with geotextile installation is ensuring proper alignment and placement of the material. Geotextiles need to be installed in a specific manner to effectively perform their intended functions, such as erosion control or soil stabilization. Achieving the right alignment can be difficult, especially in areas with uneven terrain or limited access. Another challenge is securing the geotextile in place. Since these materials are often lightweight and flexible, they can easily shift or become displaced during installation. Proper anchoring techniques, such as using staples or pins, are necessary to prevent movement and maintain the integrity of the installation. In addition, the type and condition of the underlying soil can pose challenges. Geotextiles require a stable and well-compacted base for optimal performance. If the soil is soft or unstable, additional measures such as soil stabilization techniques or geogrids may be necessary to ensure proper installation. Lastly, weather conditions can also impact geotextile installation. Wind, rain, or extreme temperatures can make the process more difficult and may require additional precautions or delays. Proper planning and coordination with weather forecasts are essential to mitigate these challenges and ensure a successful geotextile installation.

- Q: What is the effect of tunnel geotextile failure on tunnel quality

- Will affect the settlement force of the tunnel.

- Q: Can geotextiles be used in wetland restoration projects?

- Yes, geotextiles can be used in wetland restoration projects. They are often utilized to stabilize the soil and control erosion, which is crucial in wetland areas. Geotextiles can also help retain sediments and filter water, aiding in the establishment and maintenance of the wetland ecosystem.

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: How do geotextiles help with erosion control on coastal cliffs?

- Geotextiles help with erosion control on coastal cliffs by acting as a barrier that stabilizes the soil and prevents it from eroding. These synthetic fabrics are designed to allow water to pass through while trapping soil particles, thereby reducing the impact of wave action and protecting the cliff face from erosion. Additionally, geotextiles promote the growth of vegetation by providing a stable environment for plants to take root and further reinforce the soil, enhancing erosion control efforts.

- Q: How are geotextiles used in civil engineering projects?

- Geotextiles are used in civil engineering projects to provide reinforcement, separation, filtration, and drainage functions. They help stabilize soil, prevent erosion, and improve the performance of structures like roads, embankments, and retaining walls.

- Q: How about the geotextile pond

- You said to cover the fish pond, I understand is to build the bottom of the fish pond, but the use is not geotextile, but the composite geomembrane, the film is generally two layers of geotextile in the middle of a layer of geomembrane, , And geomembrane on both sides of the geotextile can prevent the bottom of the sharp objects pierced the geomembrane.

- Q: Waterproof and protective layer between which type of geotextile isolation layer

- Personally think to take impervious geotextile. Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Check the original post & gt; & gt; trouble to adopt, thank you!

Send your message to us

Geotextil Grk Polypropylene (PP) Geotextiles Industrial Nonwoven Fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords