Geotextil 200gr Anti-Grass Cloth with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

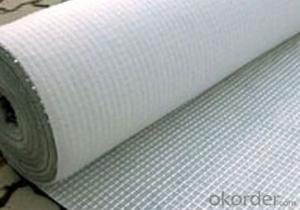

1. Product Description:

The anti-grass cloth is a kind of vertical and horizontal weaving plastic woven cloth,

It has good quality of permeability,water seepage and Prevention and control of weeds.

Anti-grass cloth can not only prevent plant roots under the ground, beautify the

environment, improve labor efficiency and economic benefit, prevention and

control of environmental pollution, reduce pesticide use, also can prevent insects

and small animals and grow.

2. Product Characteristic:

1.Prevent leakage disposal in landfill or waste water or waste dregs disposing field.

2.River bank ,lake dam ,mine remainings ,resevoir ,tunnel ,liquid storage pool(pit ,mine)

3. Anti-salt leakage in roadbed and other ground sill.

4.The plane direction laying of dam ,the vertical direction laying for ground still used in the

construction fence and waste material field.

3.Specification :

1.material:pp

2.length :50-100m

3.width:1-8m

4. Type: Geotextiles

5. Geotextile Type: Woven Geotextiles

6. Color: black

4. Reference Picture:

- Q: What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as material strength, permeability, durability, and resistance to UV degradation. The geotextiles used in these projects should have high tensile strength to withstand the forces exerted by waves and tides, as well as good permeability to allow for proper water drainage. They should also be resistant to chemicals and biological degradation, as well as have the ability to withstand harsh weather conditions. Additionally, they may need to meet specific standards or certifications set by regulatory bodies or project requirements.

- Q: Can geotextiles be used in shoreline revetment projects?

- Yes, geotextiles can be used in shoreline revetment projects. Geotextiles are commonly used to stabilize soil and prevent erosion in various civil engineering projects, including shoreline revetments. They can help reinforce the revetment structure, retain soil particles, and provide filtration, thereby enhancing the overall stability and effectiveness of the revetment system.

- Q: 200g 300g 400g non-woven geotextile price

- 200 grams of non-woven geotextile Price: 1.40 yuan. 300 grams of non-woven geotextile Price: 2.10 yuan. 400 grams of non-woven geotextile price of 2.80 yuan.

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can enhance soil nutrient availability by promoting better water and air circulation, preventing soil erosion, and increasing organic matter content. This allows for improved nutrient uptake by plants and reduces nutrient leaching, ultimately leading to healthier and more fertile soils.

- Q: What is the length of the lap in the geotextile in the tunnel?

- Lap 20 cm Huazhi geotextile material answer

- Q: GB / T geotextile sampling sampling frequency, 100 volumes equal to the number of square meters?

- Geotextile wide conventional is 6 meters, there are also more narrow and narrow, the length of conventional 50 meters or 100 meters, if the conventional calculation of a roll is 300 square meters or 600 square meters, 100 volumes will be multiplied by 100 on the line The

- Q: Can geotextiles be used in pond and lake liners?

- Yes, geotextiles can be used in pond and lake liners. They are often used as a protective layer to prevent punctures and abrasions in the liner material, and to enhance the overall stability and durability of the liner system. Geotextiles can also improve filtration and drainage properties, helping to maintain the quality and functionality of the water body.

- Q: Can geotextiles be used in shoreline stabilization projects?

- Yes, geotextiles can be used in shoreline stabilization projects. Geotextiles are commonly employed as erosion control measures in shoreline stabilization projects due to their ability to prevent soil erosion, enhance drainage, and provide structural support to the shoreline. They are often used to reinforce slopes, stabilize shorelines, and mitigate the effects of wave action, making them a valuable tool in coastal engineering.

- Q: Can geotextiles be used for reinforcement of pipeline trenches?

- Yes, geotextiles can be used for the reinforcement of pipeline trenches. They provide stability and support by preventing soil erosion and minimizing the movement of soil particles. Additionally, geotextiles can enhance the overall performance and longevity of the pipeline by reducing stress on the pipes and preventing damage caused by shifting soil.

- Q: How do geotextiles contribute to the performance of geogrid-reinforced slopes?

- Geotextiles play a crucial role in the performance of geogrid-reinforced slopes by acting as a separation and filtration layer. They prevent the mixing of soil layers, allowing for effective load distribution and reducing the risk of soil erosion. Geotextiles also enhance the stability of the slope by providing additional tensile strength and promoting water drainage, thereby minimizing the potential for slope failure. Overall, geotextiles greatly contribute to the overall performance and longevity of geogrid-reinforced slopes.

Send your message to us

Geotextil 200gr Anti-Grass Cloth with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords