Gate Valve DN350 Non-rising BS5163 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

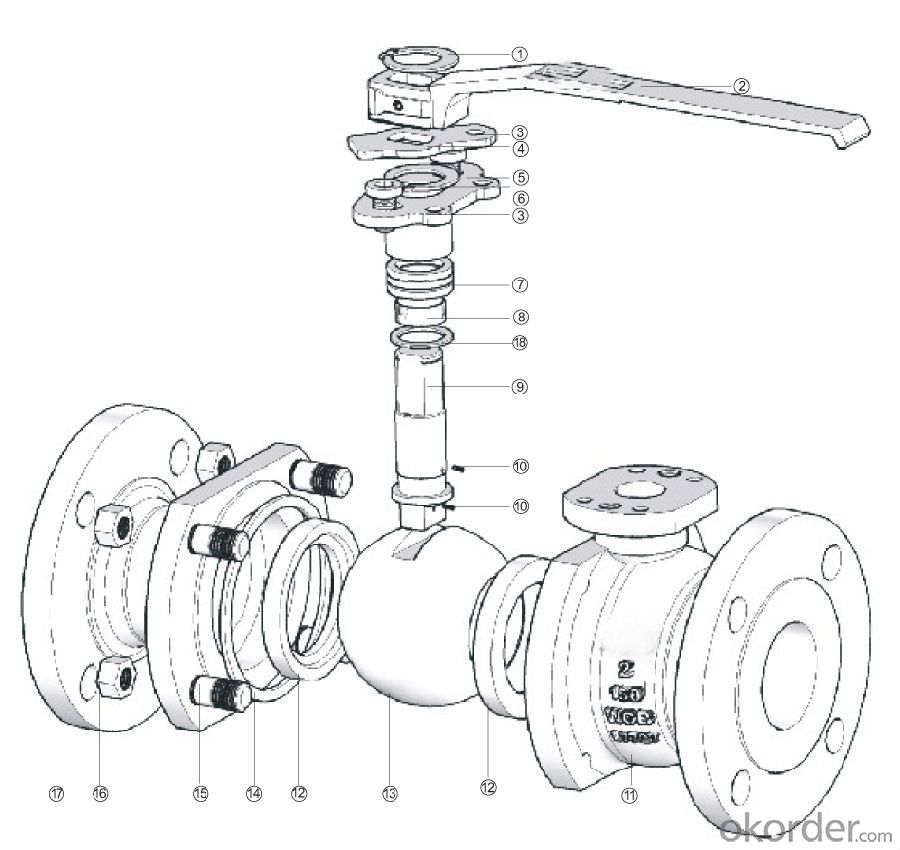

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: D37A1X9-16CB1: what does this butterfly valve mean?

- The model is composed of 7 units, the types of valves (gate valve Z, J, L, Q ball valve, throttle valve, check valve and H valve, butterfly valve, connection mode (D) internal thread 1 thread 2, welding flange 4, 6, 7, the clamp (0) electromagnetic transmission mode 1 solenoid valve, hydraulic, electric and hydraulic turbine are 2, 3, 4 and 5 gears, bevel gear, pneumatic hydraulic, 6, 7, 8, 9) pneumatic and hydraulic, electric, structure (straight or DC type 7,1 on behalf of the center plate, vertical type A (A) and LT X9) on behalf of a sealant is heat-resistant rubber, kg 16 kg, C represents the body material of carbon steel WCB, B1 on behalf of the valve plate is made of ductile cast iron plating)

- Q: How many kinds of butterfly valves are there?

- 1. according to the structure classification (1) Central sealing butterfly valve (2) single eccentric sealed butterfly valve (3) double eccentric sealed butterfly valve (4) three eccentric sealed butterfly valve2., according to the sealing material classification (1) soft sealing butterfly valve. (2) metal hard sealing butterfly valve.3. according to the form of sealing classification (1) forced sealing butterfly valve (2) pressure sealed butterfly valve.4. classification according to working pressure (1) vacuum butterfly valve. 2) low pressure butterfly valve. (3) medium pressure butterfly valve. (4) high pressure butterfly valve. (5) ultra high pressure butterfly valve.5. classification by working temperature (1) high temperature butterfly valve. (2) medium temperature butterfly valve. (3) normal temperature butterfly valve. (4) low temperature butterfly valve. (5) ultra low temperature butterfly valve.

- Q: Model specification for butterfly valves

- Various classifications of butterfly valves1. classification by structure:(1) Central sealed butterfly valve(2) single eccentric sealed coal valve;(3) double eccentric sealed butterfly valve(4) three eccentric sealed stamp valve;

- Q: The water supply pipe is the gate valve And on the cross dry pipe are the gate valve? To answer the 30

- I suggest you find out the pressure and installation position first, the condition allows, you can choose butterfly, after all, much cheaper than butterfly valve. After the completion of the project, will be mainly engaged in the acceptance of problems, there are special management of fire units.

- Q: How does the pneumatic butterfly valve control the angle of opening?

- The angle of the rotating shaft is controlled so that the angle of the butterfly valve is controlled. You just have a good electrical locator

- Q: Is the pressure test of the centerline butterfly valve checked or checked?

- GB/T12238-2008 flange and clip connection elastic seal butterfly valveRules: butterfly valve must be carried out by factory inspection and testing, inspection qualified before leaving the factory.CJ/T 261-2007 "butterfly valves for water supply and drainage."Rules: each product shall be inspected by factory and quality inspection department in accordance with table 4. After inspection, the product certificate shall be attached to the factory before leaving the factory.

- Q: Butterfly valve network and ordinary butterfly what is the difference?

- 1. The butterfly valve of the pipe network adopts an eccentric structure. When closed, it has the function of closing and tightening. The sealing performance is reliable. After opening and closing, the cover is completely sealed, and the cover is completely out of contact, so as to ensure that the sealing surface is not damaged.2, the sealing surface is made of stainless steel, corrosion resistant, high temperature resistant, long service life. With two-way sealing function, medium flow is not affected by the installation restrictions (if only one-way control medium should be used to seal the installation direction) is not affected by a single space, can be installed in the any direction.

- Q: What's the difference between butterfly valves and check valves?

- Butterfly valve is manual, only switch function.The check valve is an automatic valve, which prevents backflow of the pipe medium.

- Q: What is the meaning of American Standard butterfly valve B series

- American Standard flange connection is divided into A, B series. A series for normal flanges, B series for compact flanges. 24 "to no AB series, flange standards for B16.5, 24" above B16.47.

- Q: Butterfly valve D71X-1.6C, DN50, there is no difference between C and no C? What do you mean by "concrete"?

- D stands for butterfly valve. 71 represents the clamp type, X represents the sealing surface material, and 16 represents the valve to bear the pressure 1.6MPA, C position is the valve body material code, omitted to represent gray cast iron valve; C represents the valve body material is carbon steel.

Send your message to us

Gate Valve DN350 Non-rising BS5163 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches