Valve DN200 Non-rising BS5163 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

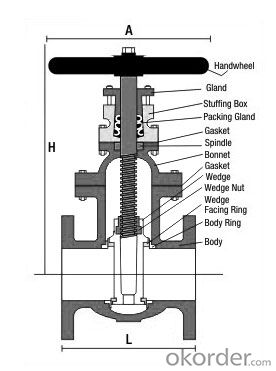

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What are the advantages and disadvantages of flat gate valves?

- The advantage of flat gate valve is that the flow resistance is small, and the flow resistance is similar to the flow resistance of short valve. The flat gate valve with guide hole is installed on the pipeline and can be directly cleaned with the cleaner. As the gate is sliding on the two seat surface, the flat gate valve can be applied to the medium with suspended particles, and the sealing surface of the flat gate valve is actually positioned automatically. The seat seal surface is not subject to thermal deformation of the valve body. Moreover, even if the valve is closed in cold condition, the thermal elongation of the stem will not cause the seal to be subjected to overload. The length of the structure is much shorter than that of the ball valve, and it is easier to start. Light plate gate valve is more refined, but the effect is exactly the same.

- Q: what are their applicable conditions? Advantages and disadvantages?

- Butterfly valve is a disc type of open and close parts reciprocating reciprocating about 90 degrees to open, close and adjust the fluid channel of a valve.Advantages: the butterfly valve has the advantages of simple structure, small volume, light weight, material consumption, installation of small size, and torque is small, simple and rapid operation, and also has good flow characteristics of regulation and sealed off, is nearly 10 years the fastest growing valve, high temperature and high pressure, and to large diameter, high sealing function of the direction, long life, good adjusting features and a valve development.Disadvantages: the butterfly valve relative to the gate, ball valve pressure loss is relatively large, it is suitable for pressure loss requirements lax piping system.Under normal circumstances, it is not suitable for high temperature and high pressure pipeline system.Valve is closed parts (valve) moving along the centerline of the valve seat, the valve stem to open or close the trip is relatively short, but very reliable cut off function, and because changes in the valve seat and the valve stroke is proportional to, is also very suitable for the regulation of traffic.Advantages: in the process of opening and closing, the friction between the disc and the valve body is smaller than that of the gate valve, so it is wearableThe opening height is generally only 1/4 of the diameter of the seat channel, so it is much smaller than the gate valveGenerally, there is only one sealing surface on the body and disc, so the manufacturing process is good and easy to maintain;Disadvantages: the flow resistance coefficient is relatively large, resulting in pressure lossUnsuitable for large caliber productionThe opening and closing moment is larger and the structure length is longer.

- Q: What is the difference between the cut-off valve and gate valve, the general will use the cut-off valve instead of gate valve

- Stop valve and gate valveThe working principle is different. The stop valve is an upward stem type, and the handwheel rotates and rises with the stem. Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open, the cut-off valve is not the same. The gate valve has no inlet and outlet direction requirements, and the cut-off valve has the required inlet and outlet!Gate valve and stop valve are shut-off valve, is the most common two valves.From the exterior, the gate valve is shorter than the cut-off valve, especially the bar valve needs a higher height space. Valve sealing surface has a certain degree of self sealing capacity, its spool depends on the media pressure tight contact with the valve seat sealing surface, to achieve tight leakage. Wedge gate valve spool angle is generally 3~6 degrees, when forced to shut down excessive or temperature changes of the valve core is easy to die. Therefore, high temperature and high pressure wedge gate valve, in the structure have taken certain measures to prevent spool stuck. The valve in the opening and closing valve and valve seat sealing surface contact and mutual friction is always so easy to wear sealing surface, especially in close off the valve, the valve before and after the great pressure, sealing surface wear is more serious.

- Q: What gate DH10016, AM

- The first Z represents the gate valve (the initial consonant of the Chinese phonetic alphabet for the gate); the second 2 represents the drive mode of the valve, that is, electro hydraulic drive.

- Q: Valve flange drawing n- up to what

- A bolt hole used to indicate a flangeThe value of N indicates the number of bolt holesUp to the numerical representation of bolt hole size

- Q: How to distinguish between gate valve and cut-off valve?

- Standard light valve professionals to answer for you, gate valve refers to the closure of parts (gate) along the central line of the vertical direction of moving valve. The gate valve is mainly used for cutting in the pipeline. The valve is a valve with a very wide, cutting device general caliber DN = 50mm use it, sometimes a small diameter cutting device also use valve, gate valve has the following advantages:Fluid resistance is small.Minor force needed for opening and closing.Medium flow is unrestricted.When opening fully, the sealing surface is eroded by the working medium smaller than the cut-off valve.

- Q: Stainless steel gate valve DN150 200300 weight, who knows?

- Valve selection of different driving methods, connection forms, structural forms, nominal pressure, sealing surface materials, lining materials, valve body material will affect the weight of the gate valve more or less, it can not be generalized.Take my commonly used Z41H-16P (i.e. PN1.6MPa) series stainless steel gate valve as an example, and the weight of DN150/200/300 is 134/192/379kg. Of course, different manufacturers may vary in weight, but not much.I hope I can help you.

- Q: What are the common standards for gate valves?

- 1, product standardsGeneral purpose valves, flanged connections, iron gate valves, GB/T 12232-2005General requirements for steel valves GB/T 12224-2005"Steel flat gate valves for pipelines" JB/T 5298-91Inspection and test of valves. JB/T 9092-1999Standard for safety evaluation of drinking water distribution equipment and protective materials GB/T 17219-1998

- Q: What is the Z15T-16C letter of the gate valve?

- The Z class code indicates the type of gate valve, gate valve is the first letter of the alphabet. The gate is manual driving mode, 1 said the connection form of gate valve for connecting thread, 5 represents the structure form of gate valve for rigid single gate, T gate said lining material of copper alloy, 16 PN1.6MPa nominal pressure valve. C said the valve body material is carbon steel.

- Q: The main question is, what are the functional differences in which case?

- The gate (gate valve) is a gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle gate valve. The direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle.Gate valve advantages: 1, fluid resistance is small,.2, opening and closing more labor-saving,.3, medium flow unrestricted, not disturbed flow, do not reduce pressure,.4, simple shape, structural length is short, manufacturing process is good, a wide range of applicationsValve shortcomings: 1, between the sealing surface is easy to cause erosion and abrasions, maintenance is more difficult,.2, big size, open need some space, opening and closing time is long,.3, the structure is more complex

Send your message to us

Valve DN200 Non-rising BS5163 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches