Galvanized World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 444 m.t.

- Supply Capability:

- 222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

the wire rod steel for construction that we offer have been used in civil construction work for years.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

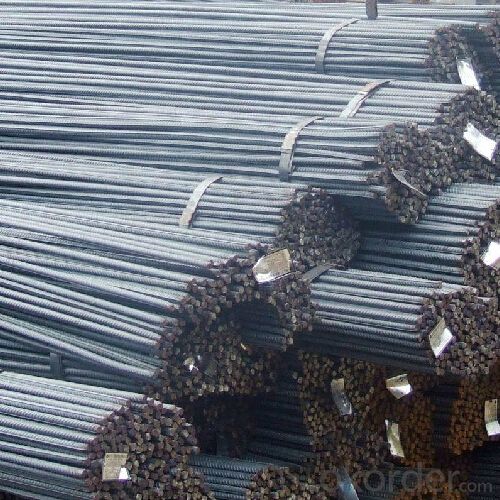

3.Wire Rod Steel for Construction Images

4.Wire Rod Steel for Construction Specification

Base metal | Cold rolled steel coil,full hard cold rolled steel coil |

Material | SGCC,SGCH, Full hard |

Grade: | Commercia.Quality(CGCC,DX51D,DC01,SPCC), Structure.quality(S280GD,S320GD,S350GD). Deep.drawing.quality(DX52D,DX53D,DX54D,DX56D) |

Standard | ASTM A653 CS/B,JIS G3302,DIN EN 10142,EN10327 |

Applications | Advertising,building trade,home electrical, Electrical industry,decoration,office furniture |

Thickness | 0.14mm-1.0mm |

Tolerance | +/-0.03mm |

Zinc layer | A40,A60,G60,G90,G115,G140,G165. Z12,Z18,Z22,Z25,Z27,Z35. Z60,Z80,Z100,Z120,Z150,Z180,Z220,Z275,Z350 |

Width | 600mm,750mm,762mm,914mm,1000mm,1219mm,1200mm,1250mm,1500mm |

Length | 1.5m,2.0m,2.438m,2.44m,2.5m,3m.,3.5m,4m,4.5m,5m |

Surface treatment | Chromated,oiled/unoiled,skinpassed,Chromated+oiled |

Surface state | Regular spangle,mini spangle,zero spangle, skinpassed |

Coil weight | 4-8tons |

ID | 508mm or 610mm |

Packing | Export standard seaworthy packing. Waterproof paper+steel sheet+bundle with steel strips(3-4pcs) |

Delivery | Based on the quantity. |

Shipment | Bulk vessel or container (FCL/LCL) |

Payment | T/T or LC at sight |

Loading port | Main port of China,Shang hai,Qingdao,Dalian,Tianjin etc. |

Yield strength | 285Mpa-305Mpa |

Tensile strength | 340Mpa-370Mpa |

5.FAQ of Wire Rod Steel for Construction

1.What is your minimum order quantity ?

Our MOQ is 500mt .

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: What are the different types of steel fencing and barriers available?

- There are several different types of steel fencing and barriers available, including chain-link fences, ornamental iron fences, welded wire mesh fences, and steel bollards. Each type offers unique features and benefits, catering to different security and aesthetic preferences.

- Q: How is steel used in the manufacturing of material handling equipment?

- Steel is commonly used in the manufacturing of material handling equipment due to its strength, durability, and versatility. It is used to create the frames, supports, and components of various equipment such as forklifts, cranes, conveyors, and storage racks. Steel's high tensile strength allows these equipment to handle heavy loads and withstand the rigors of daily use in industrial environments. Additionally, steel can be easily shaped, welded, and machined, making it an ideal choice for creating complex and customized designs required in material handling equipment.

- Q: What are the different types of steel bars used in construction?

- There are several types of steel bars commonly used in construction, including mild steel bars, deformed steel bars, high-strength deformed steel bars, and epoxy-coated steel bars. Each type has specific properties and uses, but they all provide strength and reinforcement to various structural elements in buildings and other construction projects.

- Q: What are the different types of steel coatings and finishes available for steel products?

- There are several types of steel coatings and finishes available for steel products, including galvanized coatings, powder coatings, painted finishes, and stainless steel finishes. Galvanized coatings provide corrosion resistance by applying a layer of zinc to the steel surface. Powder coatings involve electrostatically applying a dry powder onto the steel, which is then cured to form a durable and attractive finish. Painted finishes involve applying liquid paint to the steel, providing both protection and aesthetic appeal. Stainless steel finishes utilize a process of passivation or electropolishing to enhance the steel's natural corrosion resistance and create a smooth, polished surface.

- Q: How is steel used in the aerospace industry?

- Steel is used in the aerospace industry for various purposes, including the construction of aircraft structures, engine components, and landing gears. Its high strength-to-weight ratio and excellent durability make it suitable for withstanding extreme conditions and ensuring the safety and reliability of aerospace vehicles.

- Q: How are steel plates used in the fabrication of storage tanks?

- Steel plates are used in the fabrication of storage tanks to provide structural support and maintain the integrity of the tank. These plates are welded together to form the tank's shell and are strong enough to withstand the pressure and weight of the stored materials. Additionally, steel plates can be coated or lined to prevent corrosion and ensure the longevity of the tank.

- Q: What are the different types of steel valves and their applications?

- There are several types of steel valves commonly used in various industries. These include gate valves, globe valves, ball valves, butterfly valves, and check valves. Gate valves are primarily used for on/off applications and provide a tight seal when closed. They are commonly used in water treatment plants, oil and gas pipelines, and power generation systems. Globe valves have a spherical body and are suitable for regulating flow. They are frequently used in industries such as HVAC, steam systems, and chemical processing. Ball valves consist of a rotating ball with a hole that controls flow. They are versatile and widely used in applications where tight shut-off is required, such as oil and gas pipelines, chemical plants, and water treatment systems. Butterfly valves have a disc-shaped closure element that rotates to control flow. They are lightweight, cost-effective, and commonly used in applications involving large flow rates, such as HVAC systems, water supply networks, and wastewater treatment plants. Check valves, also known as non-return valves, allow flow in one direction only and prevent backflow. They are used in various applications, including pumps, compressors, and power plants. Each type of steel valve serves specific purposes based on their design and functionality. The choice of valve depends on factors such as the nature of the fluid, pressure and temperature requirements, and the specific application in industries ranging from oil and gas to water treatment and beyond.

- Q: How is steel used in the construction of pre-engineered buildings?

- Steel is used extensively in the construction of pre-engineered buildings as it offers excellent strength, durability, and versatility. It is used for the primary structural components such as columns, beams, and roof trusses, providing a strong framework for the entire building. Additionally, steel panels are commonly used for the walls and roof, ensuring a sturdy and weather-resistant enclosure. Overall, steel's high strength-to-weight ratio and ability to be easily fabricated make it an ideal material for pre-engineered building construction.

- Q: How are steel products used in the food processing industry?

- Steel products are used extensively in the food processing industry due to their durability, corrosion resistance, and ease of cleaning. They are used to manufacture various equipment and machinery, such as storage tanks, conveyors, cutting and slicing tools, and food processing lines. Steel products ensure food safety by preventing contamination and maintaining hygiene standards, making them indispensable in the food processing industry.

- Q: What are the common uses of steel in everyday life?

- Steel is widely used in everyday life for various purposes. It is commonly used in construction to create sturdy buildings, bridges, and infrastructure. Steel is also used in the manufacturing of vehicles, such as cars, trucks, and bicycles, providing strength and durability. It is utilized in household appliances like refrigerators, stoves, and washing machines due to its heat resistance and longevity. Steel is also found in cutlery, tools, and machinery. Overall, steel's versatility and reliability make it an essential material in numerous aspects of our daily lives.

Send your message to us

Galvanized World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 444 m.t.

- Supply Capability:

- 222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords