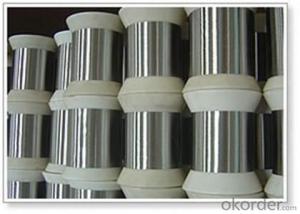

Galvanized Wire 0.13mm for Kitchen Scrubber /Mesh Scourers /Cleaning Ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Kitchen scrubber wire :

Dia:0.13mm 0.18-0.27mm,Tolerance:+/-0.005mm

Tensile Strength:650-950n/mm2

Zinc Thickness:more 7g/m2

kitchen scrubber wire is mostly used to make staple,brush,U-type nail,net, tub handle,mesh scourer and others cleaning products.

Size | Size Tolerance | Tensile Strength | Zinc Coat Thickness |

mm | +/-mm | n/mm2 | g/m2 |

0.13 | 0/-0.01 | 1000-1250 | 5 |

0.18 | 0/-0.01 | 750-950 | 7 |

0.20 | 0/-0.01 | 750-950 | 8 |

0.22 | 0/-0.01 | 700-850 | 9 |

0.24 | 0/-0.01 | 650-800 | 10 |

0.27 | 0/-0.01 | 650-800 | 11 |

0.36 | 0/-0.01 | 1000-1250 | 5 |

0.48 | 0/-0.01 | 1000-1200 | 5 |

0.55 | 0/-0.01 | 950-1210 | 5 |

0.59 | 0/-0.01 | 950-1150 | 5 |

0.70 | 0/-0.01 | 950-1150 | 5 |

0.72 | 0/-0.01 | 950-1150 | 5 |

0.78 | 0/-0.01 | 9501150 | 5 |

0.88 | 0/-0.01 | 950-1150 | 5 |

0.96 | 0/-0.01 | 950-1150 | 5 |

1.21 | 0/-0.01 | 950-1150 | 10 |

1.37 | 0/-0.01 | 950-1150 | 18 |

1.59 | 0/-0.01 | 950-1150 | 18 |

1.83 | 0/-0.01 | 950-1150 | 18 |

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Look at that oil and then choose the emulsifier To use the all-around emulsifier for oil and other oil Used for lubricating oil, mechanical oil and mine Oil, clutch oil, gear oil, brake oil, engine oil, ink, demoulding oil, compressor oil, refrigeration oil, vacuum pump oil, the internal combustion engine oil (1: diesel engine oil. 2: gasoline engine oil. 3: ship oil), oil bearing, guide Rail oil, hydraulic oil, hydraulic oil, metal processing oil dynamic tools, electrical insulating oil, oil, heat conduction oil, rust-proof oil, special occasions, oil, turbine oil, quenching oil, fuel oil, oil have oil selection and other occasions Engine oil emulsifier, no oil emulsifier is the domestic initiative of non-toxic + environmental protection + high efficiency emulsifier. For the removal of oil emulsifier and oil emulsifier, nano-oil emulsifier is used for the removal of oil and oil emulsifier in addition to oil and inorganic oil

- Q: What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q: What are the benefits of sanitation

- Love, what do you say is the advantage of washing your car every day

- Q: How to keep the equipment clean

- The equipment needs to protect the electric motor circuit and the structure that need to adjust often is good! ~

- Q: What is the pool cleaning equipment

- That should see you need to manually or automatic, manual cleaning equipment include: trolley, water pump, the suction sewage pipes, telescopic rod, suction pool head, pipe bend, and so on. Fully automatic is a complete set of facilities, which is ready to go directly to the water.

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: Is it ok to clean the car with a dry ice cleaner?

- High pressure water gun. Spray the cleaning agent for 5 minutes, start the car, then charge again. Be careful to avoid high pressure packs, electrical appliances, computer boards, and air intake.

- Q: The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- It's usually a person + device approach

- Q: It is best to wash mechanical equipment using that cleaner

- See what equipment needs to be cleaned, the current cleaning agent is nutritionally ionized, non-ionized... Principle: 1. The cleaning agent shall not be related to damage, corrosion and pollution. Effectively remove dirt; You can satisfy these two principles

- Q: Is there any molding equipment in the car engine?

- You don't want to take the engine apart and you want to clean up the carbon in it? It's going to be a big problem. Be careful. In case the carbon is filled with oil filters, there is a precedent for the effects of a short period of oil. If it's an engine that's removed and the parts of the engine are cleaned, you can use an ultrasonic cleaning machine (I guess you don't mean that). This is the same as weight loss, normal maintenance is crucial, once the carbon is much carbon, processing is difficult.

Send your message to us

Galvanized Wire 0.13mm for Kitchen Scrubber /Mesh Scourers /Cleaning Ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches