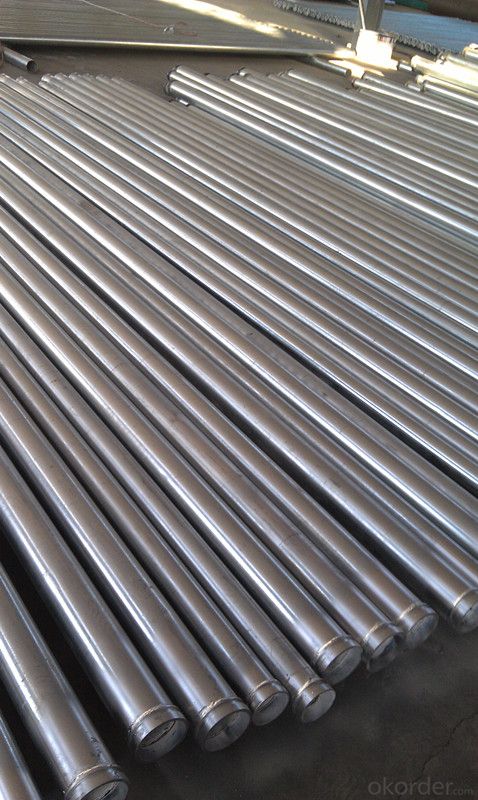

Galvanized Victaulic Shouldered grooved Pipe for mining

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | Shouldered Grooved pipe |

Outside Diameter(mm) | 60.3mm-425mm |

Wall thickness(mm) | 2mm-20mm |

Certification | FM/UL; SGS/BV |

Standard | 1.ASTM A106/A53 GR.A; ASTM A106/A53 GR.B; ASTM A53/A106 GR.C 2.APL 5L GR.B, API 5CT J55, K55, N80 3.ASTM, BS,DIN, EN |

Grade | A, B, C, ST33, ST37, ST35.8, ST45-8, ST45-4, ST52 |

Place of Origin | Hebei Cina |

Face finished | 1.Manual polished 2.mechanical polished 3.black paint on the face 4.Shoulder Grooved on both ends 5.Galvanized or Colour Painting |

Export | Europe, South America, the Middle East, Africa, Asia and other countries and regions, well received by consumers! |

Process Method | 1.Cold Drawn 2.Cold rolled 3.Hot rolled 4. Hot expanded |

Application | Tube with hollow cross-section, a large number of channels for transporting fluids, such as the transportation of oil, natural gas, gas, water and some solid materials, pipes, etc.. |

Package | 1.Inner Packing:Caps at both ends, steel strong trips on every bundle 2.Outer Packing:Standard export package or as per clients' requirements |

- Q: Can steel pipes be used for underground irrigation systems?

- Yes, steel pipes can be used for underground irrigation systems. Steel pipes are a popular choice for irrigation systems due to their durability, strength, and resistance to corrosion. They can withstand the pressure and stress of being buried underground and can last for many years without the need for frequent maintenance or replacement. Steel pipes also have a smooth interior surface, which allows for efficient water flow and reduces the risk of clogging. Additionally, steel pipes are readily available in various sizes and can be easily customized to meet specific irrigation system requirements. However, it is important to ensure that the steel pipes used for underground irrigation systems are properly coated or treated to prevent corrosion and prolong their lifespan.

- Q: Can steel pipes be used for oil and gas pipelines?

- Yes, steel pipes can be used for oil and gas pipelines. Steel pipes are commonly used in the oil and gas industry due to their strength, durability, and resistance to corrosion. They can withstand high pressure and extreme temperatures, making them suitable for transporting oil and gas over long distances.

- Q: How are steel pipes coated for protection against external elements?

- Steel pipes are coated for protection against external elements through a process called pipeline coating. This involves applying a layer of protective material, such as epoxy or polyethylene, onto the surface of the steel pipes. The coating acts as a barrier, preventing corrosion and damage from external factors like moisture, chemicals, and UV radiation. This protective coating ensures the longevity and durability of the steel pipes, even in harsh environments.

- Q: Are steel pipes suitable for underground chemical transport?

- Steel pipes are widely regarded as appropriate for transporting chemicals underground because of their high strength and durability. They have the ability to endure the pressure and weight of the soil above, rendering them impervious to harm or collapse. Furthermore, steel pipes possess corrosion resistance, which is vital when conveying chemicals that might react with or corrode other substances. They also have the capability to handle a wide range of temperatures, making them suitable for transporting chemicals that necessitate specific temperature conditions. Nevertheless, it is crucial to carefully consider the particular chemical being transported and seek advice from experts in chemical engineering or pipeline design to guarantee the compatibility of the steel pipes with the chemical and the implementation of any necessary safety precautions.

- Q: How are steel pipes used in petrochemical plants?

- Steel pipes are extensively used in petrochemical plants for various applications such as transporting fluids, gases, and chemicals. These pipes are commonly used for the transfer of raw materials, intermediates, and finished products within the plant. They are also utilized for process lines, cooling systems, and as structural components in petrochemical plants. The durable and corrosion-resistant nature of steel makes it an ideal choice for withstanding the harsh conditions and high-pressure environments typically found in these facilities.

- Q: Galvanized steel pipe DN100 and SC100

- DN is the meaning of "bore", also expressed in water supply and drainageSC is welded steel pipe, generally GB tube, that is, thick walled steel pipe, look at the design requirementsMT refers to the wire tube, usually thin-walled tube, there are KBG and JDG

- Q: What is the difference between steel pipes and cast iron pipes?

- The main difference between steel pipes and cast iron pipes lies in their composition and properties. Steel pipes are made from an alloy of iron and carbon, which gives them high strength and durability. They are also resistant to corrosion and can withstand high pressure and temperature conditions. On the other hand, cast iron pipes are made from molten iron, which provides them with excellent soundproofing capabilities and resistance to fire. However, cast iron pipes are more prone to corrosion and can be brittle, making them less suitable for high-pressure applications.

- Q: Can steel pipes be used in the automotive industry?

- Yes, steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. The high strength, durability, and heat resistance of steel make it an ideal material for handling the demands of the automotive environment.

- Q: How are steel pipes used in HVAC systems?

- Steel pipes are commonly used in HVAC systems for transporting hot or cold water, as well as other fluids like refrigerants and condensate. They are durable, resistant to corrosion, and can withstand high pressure, making them ideal for carrying fluids throughout the system. Steel pipes are typically used for water supply lines, steam distribution, and hydronic heating and cooling systems in HVAC installations.

- Q: How do you calculate the weight of a steel pipe?

- To calculate the weight of a steel pipe, you would need to know the dimensions of the pipe, specifically the outer diameter (OD), wall thickness, and length. Firstly, you need to determine the cross-sectional area of the pipe. This can be done by subtracting the inner diameter (ID) from the outer diameter (OD) and dividing the result by 2 to get the radius. Then, you can use the formula A = πr^2 to calculate the area. Next, multiply the cross-sectional area by the length of the pipe to get the volume. The formula for volume is V = A * L, where A is the cross-sectional area and L is the length. Finally, to calculate the weight of the steel pipe, you need to multiply the volume by the density of steel. The density of steel is typically around 7850 kilograms per cubic meter (kg/m^3) or 0.2836 pounds per cubic inch (lb/in^3). The formula for weight is W = V * ρ, where V is the volume and ρ is the density of steel. It's important to note that if you are working with different units, you will need to convert them to match the units of the density. For example, if the length is in feet and the density is in pounds per cubic inch, you would need to convert the length to inches before performing the calculations. Remember to double-check your measurements and calculations to ensure accuracy.

Send your message to us

Galvanized Victaulic Shouldered grooved Pipe for mining

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords