Galvanized Gabion Box for Civil Engineering 2mx1mx1m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

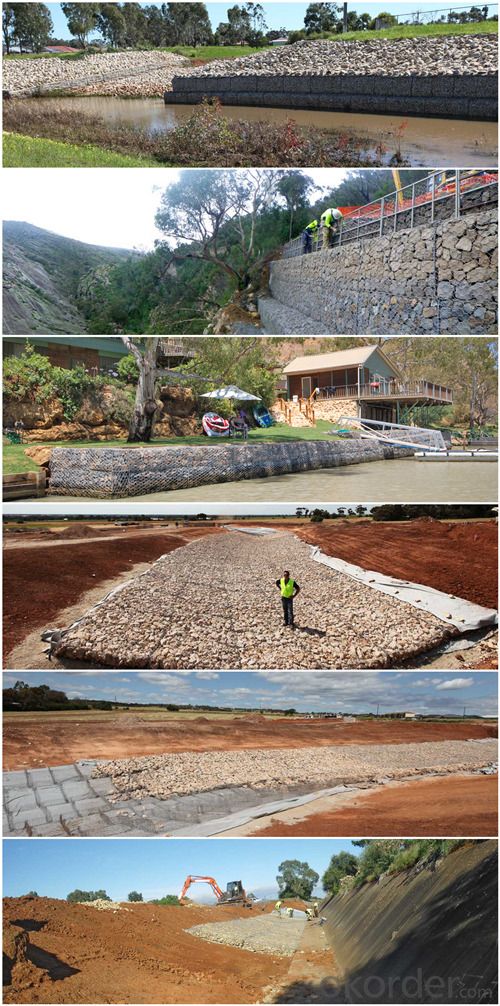

Gabion Box-a double-twisted wire mesh container of variable sizes, uniformly partitioned into internal cells, interconnected with other similar units, and filled with stone at the project site to form flexible, permeable, monolithic structures such as retaining walls, sea wall, channel linings, revetments, and weirs for erosion control projects.

Gabion Mattress-a double-twisted wire mesh container uniformly partitioned into internal cells with relatively small height in relation to other dimensions, having smaller mesh openings than the mesh used for gabions; revet mattresses are generally used for riverbank protection and channel linings.

| Table 1-Sizes for Gabion Box and Gabion Mattress | |||

| L (m) | W (m) | H (m) | # of Cells |

| 2 | 1 | 1 | 2 |

| 3 | 1 | 1 | 3 |

| 4 | 1 | 1 | 4 |

| 2 | 1 | 0.5 | 2 |

| 3 | 1 | 0.5 | 3 |

| 4 | 2 | 0.3 | 4 |

| 6 | 2 | 0.3 | 6 |

| Table 2-Standard Mesh Wire | |||

| Mesh Type | D (mm) | Mesh Tolerance | Mesh Wire (mm) |

| 8x10 | 83 | ±10% | 2.70, 3.00mm |

| 6x8 | 64 | ±10% | 2.20mm |

| Table 3-Standard Wire Diameters | |||||

| Wire Diameter ø mm | 2.20 | 2.70 | 3.00 | 3.40 | 3.80 |

| Wire Tolerance (±) ø mm | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Min. Qty of Zinc gr/m2 | 214 | 244 | 259 | 259 | 275 |

Double-twisted wire gabions and gabion mattresses are classified according to coating, as follows:

Style 1, consists of double-twisted wire mesh made from wire which is zinc coated before being double-twisted into mesh. Fasteners, lacing wire, and stiffeners are produced from zinc-coated wire.

Style 2, consists of double-twisted wire mesh made from wire which is coated with Zn-5A1-MM before being double-twisted into mesh. Fasteners, lacing wire, and stiffeners are also produced from Zn-5A1-MM coated wire.

Style 3, consists of double-twisted mesh, lacing wire, and stiffeners as Style 1 & 2 and overcoated with PVC. Fasteners shall be of stainless steel wire.

Gabions Production Process:

Case Study of Gabions and Gabion Mattresses:

- Q: What is the process of the screen printing process?

- The screen has a flat weave, twill weave, semi-woven, all woven. White screen exposure easily lead to diffuse reflection, golden, red, amber absorption of ultraviolet light, can prevent halo

- Q: Screen printing and other printing methods of the difference

- or the order quantity is not high, from a few to tens of thousands of pieces can be operated. Ink layer thick, thick color. Generally less printed continuous tone, mostly in the field of color majority.

- Q: What is the commonly used mapping software for screen printing?

- screen printing is a stencil printing, it is printed with India, embossing, gravure together known as the four printing methods. The stencil printing includes transcripts, engravings, stencils and screen printing.

- Q: Screen printing ink firmness problem

- If not enough, it can only change solvent-based ink, the solvent ink tension is small, ink layer spread, drying speed, adhesion will be much better, but the volatile substances on the human body and the environment is harmful, and flammable and explosive, need

- Q: Screen printing, how to choose the screen

- Stainless steel screen printing network tension good strength high printing effect good for printing precision products such as solar panels circuit board printing

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: What is the screen printing plate?

- Silk cloth is generally the quality of domestic and imported polyester is far worse.

- Q: Screen printing and printing the difference

- Full name screen printing is a stencil printing, it is printed with flat, embossed, gravure together known as the four printing methods.

- Q: What are the characteristics of screen printing?

- Screen printing generally has the following characteristics: not subject to printing the size and shape of the restrictions, the layout of the soft pressure small

- Q: What is the principle of screen printing?

- When printing, the ink through the mesh of the mesh on the substrate to re-form graphics / text.

Send your message to us

Galvanized Gabion Box for Civil Engineering 2mx1mx1m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords