Galvanized Gabion Box 1m*1m*2m From Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Gabion Box

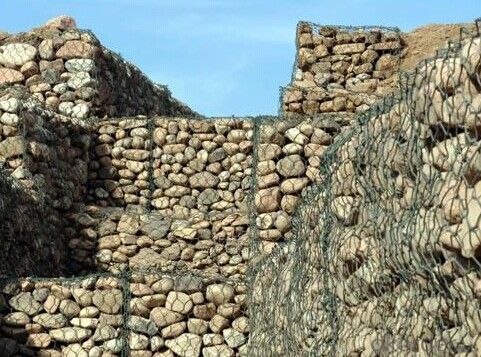

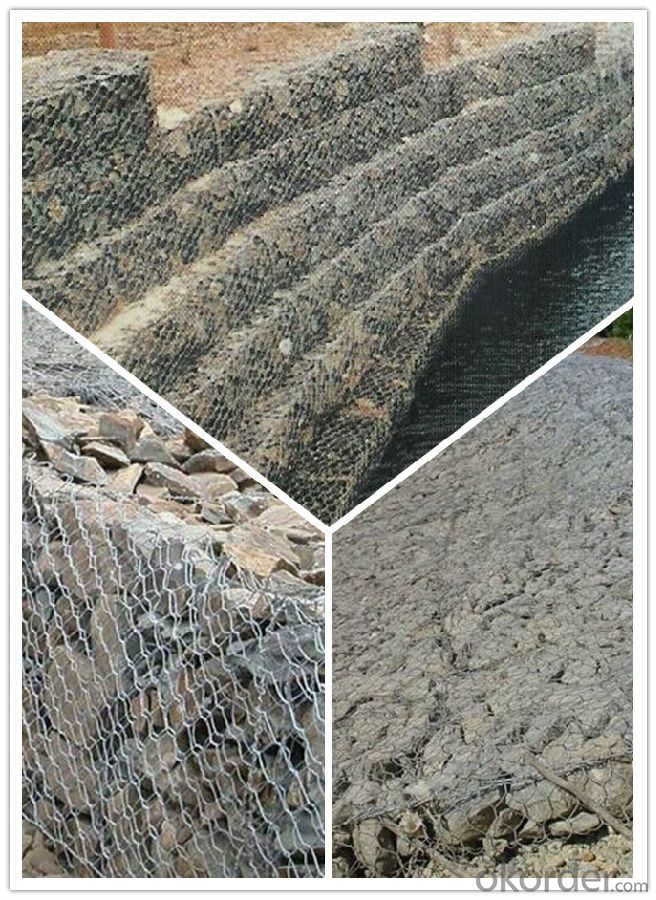

Box are made of double - twisted hexagonal wire mesh. To fill with stones at the river bank or seaside to stop flood, on the mountain prevent rock falling.

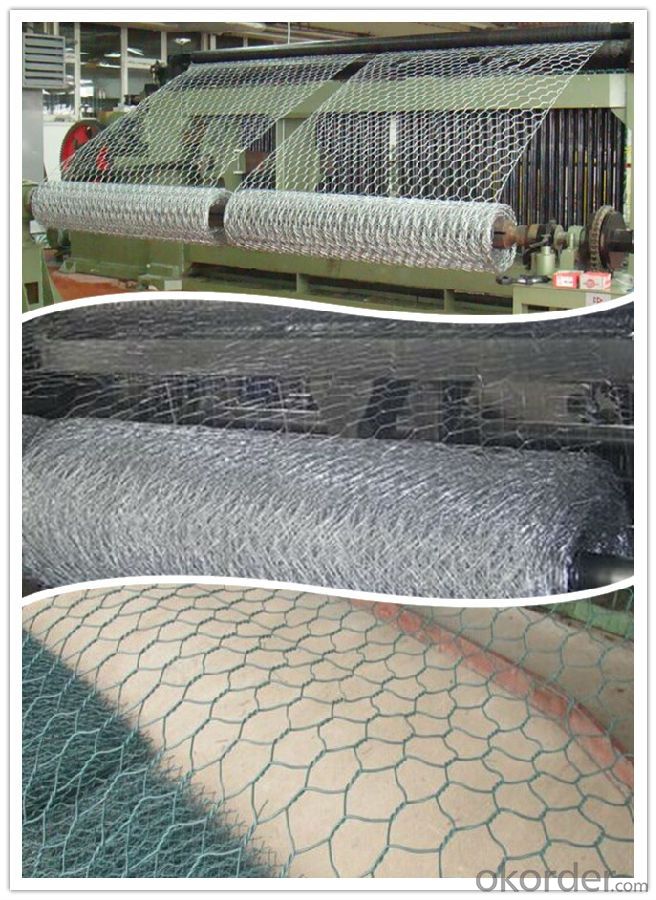

1. Gabion box materials: Hot dipped galvanized wire and PVC coated galvanized wire, Galfan coated wire

2. Gabion box mesh wire: 2.0mm, 2.2mm, 2.7mm, 3.0mm,

3. Gabion box selvage wire: 2.4mm, 2.7mm, 3.4mm, 3.9mm

4. Gabion box mesh size: 6*8cm, 8*10cm, 10*12cm, 12*15cm

5. Gabion box lacing wire: 2.2mm, 5% of gabion weight

6. Gabion box Zinc coating: 225-275g/m2 according to EN 10224-2

7. Gabion box size: 1x1x1m, 2X1X0.5m, 2X1X1m, 3X1X1m, 4X2X0.5m, 6X2X0.3m

8. Gabion box Steel according to EN 102182, Tensile strength between 380N/mm2 and 500N/mm2

Gabion Box Packing:

Gabion box applications:

1)Control and guide of water or flood

2)Flood bank or guiding bank

3)Preventing of rock breaking

4)Water and soil protection

5)Bridge protection

6)Strengthening structure of soil

7)Protection engineering of seaside area

| Hexagonal Wire Mesh Gabion Wire Mesh Specification | |||

| Length*Width*Height | 2m x 1m x 1m, 3m x 1m x 1m, 4m x 1m x 1m, 2m x 1m x 0.5m, 4m x 1m x 0.5m or Customized | ||

| Mesh Size | 60*80; 80*100; 100*120 as standard, or customized | ||

| Wire Diameter | 2.00mm to 4.0m or customized | ||

| Surface Finish | Electro Galvanized Hot Dipped Galvanized Galfan Coated PVC Coated | ||

| Weaving | Double Twist | ||

| PVC Coated Gabion Box Specification | |||

| Opening (mm) | Wire Diameter(Metal Wire) (mm) | Wire Diameter (PVC Coate)/ Inner/Outside(mm) | |

| 60X80 | φ2.0-2.8 | φ2.0/3.0-2.5/3.5 | |

| 80X100 | φ2.0-3.2 | φ2.0/3.0-2.8/3.8 | |

| 80X120 | φ2.0-3.2 | φ2.0/3.0-2.8/3.8 | |

| 100X120 | φ2.0-3.4 | φ2.0/3.0-2.8/3.8 | |

| 100X150 | φ2.0-3.4 | φ2.0/3.0-2.8/3.8 | |

| 120X150 | φ2.0-4.0 | φ2.0/3.0-3.0/4.0 | |

- Q: What are the reasons for the hair making of the screen plate?

- Film thickness to touch the edge of the brush slightly raised the feel is better. (Coating method can be used in this way to try: screen inside coated 2-3 times, and then dry, to be completely dry After the screen outside the continuous coating 2-3 times. (Outside the number of coating can be based on the final thickness of the corresponding increase or decrease)

- Q: Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

- Q: The difference between screen printing characteristics

- Advertising, curtains, curtains. For example, the current general offset printing, embossing and other printing methods can print the size of the largest size of the whole sheet, more than the full size, it is subject to mechanical equipment restrictions.

- Q: What is the commonly used mapping software for screen printing?

- It is characterized by enlargement of the image will not be distorted, and resolution has nothing to do, apply to graphic design, text design and some logo design, layout design.

- Q: How to clean the screen plate

- Directly with tap water rushed, and can be used with a cloth or soft brush brush. That the white mortar is water-based, then your screen board must also be water-based, so the fastest wash with tap water, the cost is the lowest, water-based stencil is not afraid of water, rest assured that red will not rot, unless you in the water Plus a release agent and the like. (But the water-based screen in the prepress are generally on the curing agent, or else is not easy to wash easily)

- Q: Screen printing has several characteristics

- The principle of stencil printing is: the printing plate (paper version or other version of the foundation to produce through the ink hole) in the printing, through a certain pressure to the ink through the hole version of the hole transferred to the substrate (paper, ceramics

- Q: Screen printing, how to choose the screen

- Textile printing using 60-135 mesh, oily ink in plastic / metal, etc. hard surface printing using 100-180 mesh, printed circuit board use more than 200.

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: What is the screen printing plate?

- Silk cloth is generally the quality of domestic and imported polyester is far worse.

- Q: Screen printing and printing the difference

- Printing (Graphic Arts, also use Graphic Communications that is graphic transmission) is the text, pictures, photos, security and other originals by plate making,

Send your message to us

Galvanized Gabion Box 1m*1m*2m From Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords