Galvanized Corrugated Steel Plate / Sheet in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

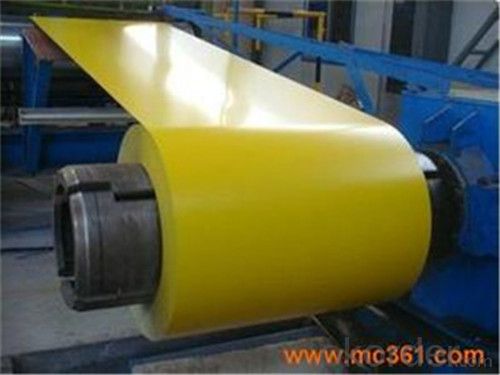

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Characteristic of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What is stainless steel coil used for?

- Stainless steel coil is highly valued in numerous industries for its long-lasting nature, ability to resist corrosion, and attractive appearance. One of its most frequent uses occurs in the manufacturing and construction fields, where it is employed in the creation of a wide array of products such as kitchen appliances, cutlery, automotive components, and architectural structures. Its resistance to corrosion makes it especially suitable for applications that necessitate protection against moisture, chemicals, and harsh environmental conditions. Moreover, the strength and ability to withstand high temperatures make stainless steel coils well-suited for use in industrial equipment, heat exchangers, and piping systems. Furthermore, the sleek and contemporary look of stainless steel is often preferred in the design and production of consumer goods like furniture, jewelry, and decorative items. In summary, stainless steel coil is a versatile material that is extensively utilized in a variety of industries due to its exceptional mechanical properties, ability to resist corrosion, and its versatility in terms of appearance.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: How are steel coils used in the manufacturing of construction cranes?

- Steel coils are used in the manufacturing of construction cranes to form the structural components, such as the boom, mast, and jib. These coils are processed and shaped through a series of cutting, bending, and welding techniques to create the strong and durable framework necessary for the crane's operation.

- Q: How are steel coils used in the manufacturing of storage cabinets?

- Steel coils are used in the manufacturing of storage cabinets as they are processed and shaped into sheets or panels, which are then cut, formed, and assembled to create the structural framework and outer shell of the cabinets. The steel coils provide strength, durability, and rigidity to the cabinets, ensuring their ability to withstand heavy loads and provide long-lasting storage solutions.

- Q: How do steel coils contribute to the marine industry?

- Steel coils are a crucial component in the marine industry as they have various applications that contribute to the development, maintenance, and efficiency of marine vessels. Firstly, steel coils are used in the construction of ships and offshore platforms. Their high strength and durability make them ideal for the hull structure, ensuring the integrity and safety of the vessel, even in harsh marine environments. Additionally, steel coils are utilized in the fabrication of various marine equipment and components. For instance, they are used to manufacture propellers, shafts, and rudders, which are essential for steering and propelling ships. The use of steel coils in these parts ensures their resilience against the corrosive effects of seawater, thus increasing their lifespan and reducing maintenance costs. Moreover, steel coils are employed in the production of marine pipelines and oil rig infrastructure. These coils are transformed into pipes and tubes that are used in the transportation of oil, gas, and other fluids. The strength and corrosion resistance of steel coils are vital in ensuring the reliability and safety of these pipelines, as they need to withstand extreme pressure and exposure to saltwater. Steel coils also play a role in the marine industry's maintenance and repair processes. When a ship undergoes renovations or repairs, steel coils are often used to replace damaged or corroded sections of the vessel. The versatility of steel coils allows them to be molded and welded into various shapes and sizes, making them suitable for different repair applications. Overall, steel coils contribute significantly to the marine industry by providing the necessary strength, durability, and corrosion resistance for the construction, maintenance, and efficiency of marine vessels. Their applications in shipbuilding, component fabrication, pipeline construction, and repair processes make them indispensable to the development and sustainability of the marine industry.

- Q: Is Stainless steel called that because.....a. Its stains lessORb. Its virtually stainless (it can't stain).Lol do you know the correct answer?????

- Stainless Steel is named that because when compared to untreated steel it is virtually stainless. It is virtually stainless, and harbors very little germs and bacteria. That is why it has been the standard in the food industry for years.

- Q: What are the common thicknesses available for steel coils?

- The specific requirements and applications determine the available common thicknesses for steel coils. However, various industries commonly produce and use certain standard thicknesses. Typically, steel coils can range in thickness from 0.005 inches to 0.5 inches or more, depending on the type of steel and its intended use. For instance, in automotive manufacturing, where steel coils are utilized for body panels and structural components, the thicknesses commonly range from 0.5 mm (0.020 inches) to 3 mm (0.118 inches). In the construction industry, steel coils are employed for roofing, siding, and structural framing. The common thicknesses can vary from 0.014 inches to 0.062 inches, depending on the specific application and structural requirements. Similarly, appliances manufacturing, such as refrigerators, washing machines, or HVAC systems, frequently employ steel coils with thicknesses ranging from 0.018 inches to 0.035 inches. It is important to note that these are only a few examples of common thicknesses, and variations can occur based on the specific requirements of different industries and applications. Custom thicknesses can also be produced upon request to meet unique needs in various sectors.

- Q: What are the advantages of using pre-painted steel coils?

- There are several advantages to using pre-painted steel coils. Firstly, pre-painted steel coils have a protective coating applied during the manufacturing process, which makes them resistant to corrosion and increases their lifespan. Additionally, the pre-painted coating provides a smooth and aesthetically appealing finish, eliminating the need for further painting or finishing. This saves time and money on additional coatings or treatments. Moreover, pre-painted steel coils are available in a wide range of colors and finishes, allowing for greater design flexibility and customization. Lastly, pre-painted steel coils are easy to install, lightweight, and have excellent durability, making them an ideal choice for various applications in construction, automotive, and other industries.

- Q: How are steel coils inspected for flatness?

- Steel coils are inspected for flatness using various methods, such as visual inspection, measuring the crown or center buckle, and conducting a straight edge test. These techniques help assess any deviations or unevenness in the coil's surface, ensuring that it meets the required flatness standards.

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Those are all excellent quality knives so if the style of knife that you want is available from several makers it comes down to personal preference. I would go with SOG myself but the others are real good too.

Send your message to us

Galvanized Corrugated Steel Plate / Sheet in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords