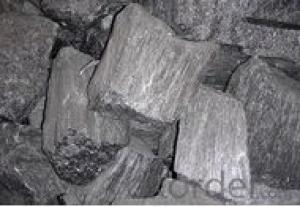

Fused Mullite 75 Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Fused Mullite:

Fused Mullite is produced by melting mixed pure quartz sand and industrial alumina in huge electric arc furnace .With the high content of mullite crystal, high melting point, excellent thermal stability, low reversible thermal expansion and resistance to thermal shock and chemical corrosion at high temperature, the fused mullite can be widely used as lining bricks in glass body kiln and large hot wind furnace in iron-making blast furnace, as well as in ceramic kiln and performance.

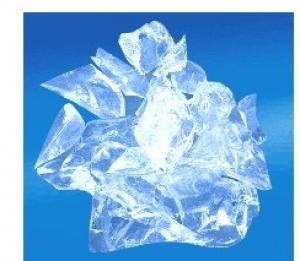

Specifications of Fused Mullite 75 :

| Chemical/Physical Analysis | WFM75 |

| Al2O3(%) | 70-77 |

| SiO2(%) | 22-29 |

| Fe2O3(%)Max | 0.5 |

| TiO2(%)Max | 0.1 |

| Na2O+K2O(%)Max | 0.4 |

| Apparent Porosity(%)Max | 4 |

| Bulk Density (g/cm3)Min | 3.05 |

| Refractoriness(℃)Min | 1850 |

Description of Fused Mullite 75:

Fused Mullite is produced by melting mixed pure quartz sand and industrial alumina in huge electric arc furnace .With the high content of mullite crystal, high melting point, excellent thermal stability, low reversible thermal expansion and resistance to thermal shock and chemical corrosion at high temperature.

Applications of Fused Mullite 75:

Fused Mullite 75 is used in the manufacture of refractory, investment cast, ceramic and electronic products where hot strength, resistance to spalling, and low thermal conductivity are important factors.

Packaging&Delivery:

Packaging Details : 1mt big bag or according to customers' requirements

Delivery:7-15 workdays after the order is confirmed

Competitive Advantage of Our Fused Mullite 75:

1.High purity

2.Competive price

3.Timely delivery and service

4.Hot oversea sales

- Q: What are the applications of refractory?

- Refractory usually refers to the inorganic non-metallic material, whose refractoriness is above 1580℃. And it can be used for necessary parts. You can search more information on the Internet. It can be used in ferrous metal metallurgy, chemical, ceramics and so on. Fire material generally refers to above 1580 ℃ refractoriness of inorganic material, where the material can be used in corrosion, the network is very strong look, we know that colored when the metallurgical, chemical-resistant ceramics, etc. of industrial production high temperature. Different things are needed in different industries.

- Q: What kinds of refractory will be used in kiln of sintering ceramics?

- If it is ordinary ceramic, you can use ordinary clay bricks and high alumina brick, adding calcium silicate board, the insulating brick and cotton fiber.

- Q: Does hardware construction materials contain refractory?

- refractory includes one kind of building materials. It is a special material and not commonly used.

- Q: What material is used to make furnace pipe of refractory bricks?

- Furnace pipe of refractory brick is an indispensable part of casting cupola. Furnace pipe is divided into upper and lower part. Radial direction and axial breathing. The upper furnace pipe adopts double layer steel structure and countercurrent air supply mode. The lower furnace pipe is made by processing integrated heat resistant steel in flange, fin and inner wall in wearing parts. The operation life is over 3000h. There is radiating rib of heating air on the edge of furnace pipe liner by using the heat of casting cupola to heat air in cupola. Hot air temperature is about 180-250℃, which contributes to improve trhe thermal efficiency of production equipment, decrease production cost and improve economic benefit of enterprises.

- Q: can slag tailings be used to be the base materials of refractory materials ?

- the rest of it can be used as refractory additives. the scale currently used clay bricks to make high-temperature liquid. It is easy to produce large amounts of liquid because of the high iron content, instead of its refractoriness. But it can be used as refractory minaralizer.

- Q: what are the types of piping insulation material fire?rating?

- Pipe insulation material Fire rating: heat conductivity coefficient(at room temperature) 0.025 grade non-combustible Class A low temperature bending ≤ 5000 breaking elongation 5,000 specifications 5000 anti-bending?strength 5000 compressive?strength 5000 special brand of high use temperature -250 ~ 150 ℃ core material, phenolic foam, form, stratiform, shape,flake.

- Q: What are the requirements on fire resistance period of C-level fireproof glass?

- Class C: The fireproof glass which only meets demand of fire integrity. This glass has advantages of transmittance, fireproofing, smoke resistance and high intensity. It can be applied to fireproof glass partition walls, fire windows and with no requirements on outdoor curtain walls, etc. The fireproof glass can be classified as composite fireproof glass and single chip fire-proof glass in terms of structure. Class B: The fireproof glass which meets demands of fire integrity and thermal radiation intensity at the same time. This glass is mostly composite fireproof glass which has advantages of transmittance, fireproofing, and smoke resistance.

- Q: Who knows the fire endurance of rock wool color plate?

- I'm glad to answer your question and offer you some of my experiences, for reference only. rock wool board is artificial inorganic fiber taking basalt as raw material and produced by melting with high temperature, which has characteristics of lightweight, non-combustible, heat absorbing, small thermal conductivity. The initial research is a common type of application in the building mainly used for industrial buildings which should be consistent with provisions in "the application types and basic requirements of building insulation materials". Successfully tested in June, 1981 Rock wool board is a new type material with fuctions of thermal insulation, fire retardant, sound absorption. The fire endurance of general rock wool board is 140-180 degrees, within two hours, better not exceed this safe period, in order to avoid security risks.

- Q: Which fireproofing materials factory is the best in Xiangyang?

- Xiangyang Shenglaide Door Technology Co., Ltd. Location: Taibai Road, Fancheng District, Xiangfan, Hubei Province Xiangyang Ai'ruite Door Technology Co., Ltd. Location: Scientific and Technical Pioneering Park, Xiangcheng District, Xiangfan, Hubei Province Xiangyang Innovation and Ideal Manufacturing Co., Ltd. Location: Xiangyang Xiangfan state Jianshe Road, Xiangzhou District, Xiangyang, Hubei Province

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fused Mullite 75 Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords