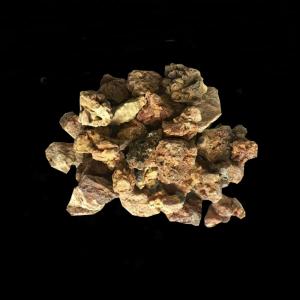

Fused Magnesite High Grade for Refractory Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Liaoning, China

Application: Refractory

Shape: Block

Material: Magnesite

Chemical Composition: Mgo;CaO;SiO2

Mgo:96%-97%

Product name: FM

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: 0-30mm etc

Sample supply: free sample

Color: Brown, white

MOQ: 25Mt

Supply Ability

Supply Ability:1000 Metric Ton/Metric Tons per Month

Grade | MgO | SiO2 | CaO | Fe2O3 | Al2O3 | Loi | B.D g/cm3 |

Dicalcium-fused magnesium | 97.00 | 0.70 | 1.40 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 0.85 | 1.60 | 0.70 | 0.20 | 0.15 | 3.20-3.30 | |

96.00 | 0.95 | 1.90 | 0.80 | 0.23 | 0.12 | 3.20-3.30 | |

Common fused magnesite | 97.20 | 0.80 | 1.10 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 1.20 | 1.30 | 0.70 | 0.20 | 0.10 | 3.20-3.30 | |

96.00 | 1.40 | 1.50 | 0.80 | 0.20 | 0.10 | 3.20-3.30 | |

Size | 0-1mm, 0-30mm, 1-15mm, 1-30mm, 200mesh or according to customer's requirements. | ||||||

Plant photos:

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Port Main port of China

Loading:

What is fused magnesite?

Fused magnesite is produced by high quality magnesite through electro- fusing, After melting, the SiO2 of material moves to the surface for the difference in the specific, so it has well grown crystals, well crystal perfection and structure homogeneity, excellent chemical stability, good corrosion resistance to slag and high strength at high temperature.

Where to apply fused magnesite?

It is widely used for gunning materials, fused magnesite ramming material, magnesite brick, magnesite chrome brick, vacuum and vacuum induction furnace, electric arc furnace refractory lining, magnesia crucible, furnace and a variety of refractory, such as large scale glass furnace by floating method, electrical furnace, convert furnace, house hold electrical appliances as electrical insulating materials,

- Q: What's the fire endurance of fire windows?

- Fire endurance of fire doors and fire windows stipulated by the fire prevention norm: Fire endurance of A class fire door or fire window is 1.2h rather than 1.5h, and fire endurance of B class fire door or fire window is 0.9h rather than 1.0h. Fire prevention code doesn't explicitly state that the fire door has thermal insulation function, so it can definitely be interpreted that the fire door only has fire integrity. For the fire door without heat-shielding performance, at certain distance from the unexposed surface, it has strong thermal radiation and is easy to hurt people. For the A class thermal insulating fire door, its fire integrity is 0.1h shorter than that of the corresponding fire door stipulated in the specification, but its heat-shielding performance and integrality is improved. All in all, compared with the specification that the fire integrity of the A class fire door should be 0.6h, it has much more improved its performance.

- Q: How to distinguish the construction fire-proof material rating?

- Currently the national standards divide building materials as follows: A1, A2, B, C, D, E, F. External wall thermal insulation fire?rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. Class A is non-combustible, class B1 flame retardant, class B2 combustible, class B3 flammable. Combustion performance grades of building materials and products are divided into class A1, A2, B, C, D, E, F. And grading of flooring materials and pipeline thermal insulation materials is also stipulated separately, whose combustion performance grade is distinguished by the subscript fl and L respectively. ie. Combustion performance grades for ordinary building materials and products are A1, A2, B, C, D, E, F; combustion performance grades for paving material are Alfl, A2fl, Bfl, Cfl, Dfl, Efl, Ffl; combustion performance grades for pipeline thermal insulation material are A1L, A2L, BL, CL, DL, EL, FL.

- Q: what's the varieties of fire-proof?sealing?material?

- Fire blocking material currently on the market include: fire stopping board, foam blocking material, flame resisting module, fire-resisting sealant, flexible organic caulking, WXY-II and fire retardant bag, etc. fire-proof?sealing?material is widely used in building construction and can ensure high-temperature flame and smoke from fires not spread to another fire?compartment, different buildings generally use different sealing methods. Pipeline is generaly sealed by pouring concrete board or mortar.

- Q: I wanna ask about the building insulation materials fire rating?

- In China, the main external insulation materials are divided into level A, level B1, level B2 and level B3. According to the current "Combustion Performance Classification Method of Building Materials", level A thermal insulation material is incombustible material and inorganic insulation material. However, there are few level A thermal insulation material on the current market, only glass wool, rock wool board, foam glass and vitrified micro bead. However, compared with level A insulation material, the organic insulation materials are popular in the market. Level B insulation material can be divided into three levels, level B1 is flame-retardant, level B2 is flammable, and level B3 is flammable. Level B1 nonflammable thermal insulation material is determined by the fire endurance of the material, in addition, different parts of material is divided differently! More common is EPS / XPS insulation boards which have added flame retardant through special treatment. B2 level of combustible insulation materials, common to EPS expanded polystyrene foam insulation board and XPS board, that is, we often say that the general board. The ignition point of this material is very low, and it will release a large amounts of harmful gases in the combustion process. level B3 flammable insulation material is a kind of thermal insulation material which mainly made of polyphenyl foamed. Since this material is highly flammable, it has been eliminated. Civil construction insulation materials, popular building insulation materials in China's current market are mainly made by three organic foam, such as EPS (molded polystyrene board), XPS (extruded polystyrene board) and PU (polyurethane)

- Q: Refractory materials are needed for casting metallurgy.

- High quality refractory materials can not be separated from the process of smelting metal and casting moulding, because the quality of melting furnace, iron / steel ladle directly affect the chemical composition of the metal liquid, and exert irretrievable influence on comprehensive quality of castings. Classification of refractory materials used in foundry smelting process: refractory brick, siliceous brick, high alumina brick, corundum brick, magnesia brick, magnesia brick, magnesia carbon brick. Unshaped refractory materials: ramming material, castable, refractory cement, silica, magnesia, coating material and light insulation material etc.

- Q: What are the construction measures of refractory material in winter? Please descriptive briefly.

- The temperature is low in winter, so refractory bulk materials should be stirred evenly on time to avoid freezing.

- Q: What is the acceptance standard of refractory?

- Feeler gauge is used to check the thickness of the refractory brickwork joint. The top of the gauge can not be sharpened. Feeler gauge is of the width of 15mm, length of 100mm and thickness of 1, 1.5, 2 or 3mm. The thickness is eligible when the depth which the feeler gauge is inserted in is less than or equal to 20mm. Ten places should be inspected per 5m2 of masonry surfaces. It is qualified when the condition in which thickness of the brickwork joint is 50% larger than a predetermined depth is not less than five times and it is excellent when the condition is no more than two times.

- Q: How is the development of Xinmi refractories industry? What's its advantages and disadvantages?

- I don't know how it has developed. Its advantage is the coal industry. You have to know the generating capacity in Xinmi thermal power plant first, and then you will know their coal cinder yield, after all, this is the raw material. Xinmi is not far away from Zhengzhou. The real estate in Zhengzhou is still good. I'm not sure about the others.

- Q: Which refractory is suitable for the tunnel kiln?

- The refractories produced by the following ten manufacturers are relatively good. They are all being the top ten brands! 1. king coconut (Chinese well-known trademarks, famous brand, the nation's largest manufacturer of wood panels, large building materials chain enterprises, Hangzhou king coconut Holding Group Co., Ltd.) 2. Fuxiang (founded in 1998, the leading professional sheet production outstanding enterprises, Fuxiang Industrial Co., Ltd.) 3. Bunny (China famous brand, China Top brand, plywood industry iconic brand, large listed companies, high-tech enterprises, Edward Bunny decoration materials Co., Ltd. 4. new Millennium boat ( Chinese well-known trademarks, famous trademarks in Zhejiang, Zhejiang famous brand, well-known trademarks in Hangzhou, Zhejiang Province key forestry enterprises, the Millennium boat Group Hangzhou Huahai Wood Industry Co., Ltd.) 5. Jin Luli (China famous brand, Chinese brand-name products, Shandong Province, to wood-based panels and steel-based enterprises, hundred private enterprises in Shandong Province, Luli Group Co., Ltd.) 6. Albert (professional fire protection board development / production and marketing of the modern manufacturer, the introduction of advanced production technology industry HPL) 7. desert oasis (China famous brand lumber, China's top ten brands plate, sheet famous Chinese brand, oasis Wood) 8. Peng Che-hung (professional fire protection board development / production and marketing of the modern manufacturer, the introduction of advanced production technology industry HPL ) 9. Worldwide (professional magnesium fire plate glass production and sales of integrated large-scale well-known enterprises, famous brands Firewood industry) 10. Mogan (national key high-tech enterprises, China's largest and most influential environment-friendly decorative materials production one of the enterprises, Zhejiang Hua Yunfeng new material Co., Ltd.)

Send your message to us

Fused Magnesite High Grade for Refractory Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords