Furnace Used Ceramic Fiber Heaters for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

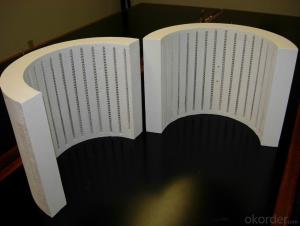

We use the imported High purified raw material to produce the box heater, and the heater will be installed by different ways as customer required. The box continuous working temperature is 0-1200℃,it only needs 12 minutes the temperature can reach to 1000℃

Application:

Ceramic fiber shaped products are produced by vacuum-filtrating forming process. Fibers of various shaped for various circumstances are available according to customer's requirements. The specifications and the temperature requirements all depends on the customer.

We use the imported High purified raw material to produce the tube heater, and the heater will be installed by different ways as customer required.

Ceramic Fiber Insulated Heater is available with heating element embedded in vacuum forming or installed on machined ceramic fiber blocks, in form of flat panel, half tube, tube or any custom made shapes.

Advantage:

◆Precise size

◆Short heating time

◆Easy installation

◆Low dust

◆Energy saving

◆Long service life

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

◆Low light

FURNACE INNER SIZE(D×W×H) | Voltage(V) | Power(W) | Service Temp(℃) |

550×460×60 | 380 | 7500 | 0~1200 |

1350×400×60 | 380 | 10500 | 0~1200 |

1620×290×60 | 380 | 8000 | 0~1200 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of ceramic fiber heaters?

The ceramic fiber heaters will be used in various electric heating furnaces,

smallest laboratory furnace, largest production furnace, pipe heating etc

---------What type of ceramic fiber heaters we can produce?

1. Flat panel

2. Half tube

3. Round tube

4. Box shape

5. Customers required shapes

----------what advantages of ceramic fiber heaters?

1. Precise size

2. Short heating time

3. Easy installation

4. Low dust

5. Energy saving

6. Long service life

7. Low thermal conductivity

8. High tensile strength

- Q: Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q: What is the process of producing ceramic fiber mats?

- Specifications:Diameter 10mm-- infinityProduct features:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q: What is ceramic fiber paper?

- Ji'nan Huolong ceramic fiber paper is made from high purity ultrafine ceramic fiber cotton by dispersing agent evenly dispersed, high temperature binder and a dilution ratio of the mixed, heated by microwave drying was prepared.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- (2) the density of Tao Xianzhan is below 200Kg/m3 (generally 160kg / m3), only light heat resistant lining L / 6 - 1/7.(3) the heat capacity is only 1 / 9 of light heat resistant lining and light fireclay bricks.(4) the ceramic fiber is stable in high temperature, the residual shrinkage rate is very small, and it needs no shrinkage or expansion joints, so it is easy to construct.(5) the coefficient of thermal conductivity is small. On the hot surface temperature of 600 degrees Celsius (the average temperature of 366 DEG C) when the orientation coefficient is 0.078W / (M. K); 900 (the average temperature is 551 DEG C) of O.096W / (m.k); 1100 (the average temperature is 678 DEG C) of 0.125W / (m.k), is about light fireclay bricks 1 / 8, for the light at 1 / 10 heat resistant lining.(6) sound insulation effect is good. The ceramic fiber coating can reduce the high-frequency noise with frequency less than 1000Hz, and also absorb some low-frequency noise.(7) it has a certain tensile strength.(8) good chemical stability.(9) good elasticity (78% at normal temperature), easy to transport and install.(10) it has better resistance to airflow erosion, and can withstand 30 - 50m/s airflow erosion.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Inorganic refractory: CeramicHeavy industries (of fire furnaces)There are also organic polymers: halogen and halogen free construction"Ceramic fiber materials are generally used in heat insulation places, and can be used in all high temperature industries.

- Q: The characteristics of ceramic fiber paper

- 1, high strength tear resistant 2, high flexibility 3, low slag ball content 4, accurate thickness 5, thermal shock 6, very low thermal conductivity

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

- Q: How to choose the right ceramic fiber and aluminum silicate products?

- When choosing ceramic fiber, aluminum silicate fiber products,1, according to the use of temperature to choose,1050, ordinary ceramic fiber, aluminum silicate fiber, suitable for 850 degrees Celsius temperature insulation1260 standard ceramic fiber aluminum silicate fiber, suitable for 1000 degrees Celsius temperature insulation1260 high purity ceramic fiber, aluminum silicate fiber, suitable for 1100 degrees Celsius temperature insulation1400 high alumina ceramic fiber aluminum silicate fiber is suitable for 1200 degrees Celsius temperature1400, zirconium containing ceramic fiber, aluminum silicate fiber, suitable for 1280 degrees Celsius temperature insulation

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- New product -- soluble ceramic fiber blanket. Ten years ago have been produced, but not up, from the beginning of 2015, Japan, Europe and other countries on the ceramic fiber products safety index is getting higher, the soluble ceramic fiber is also hot again, also with the help of a power plant thermal ceramic dragon pipe insulation insulation with 600 DEG 30mm thick aluminum silicate fiber blanket. The trial production of a batch of 20 tons of soluble ceramic fiber blanket.

Send your message to us

Furnace Used Ceramic Fiber Heaters for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords