Fully Drawn Yarn FDY Yarn High Strength Eco-Friendly

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

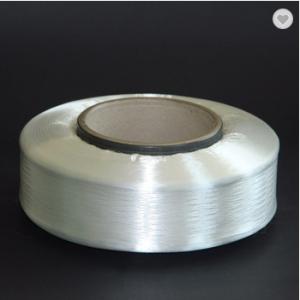

Product Description of FDY Yarn

Material | 100% polyester |

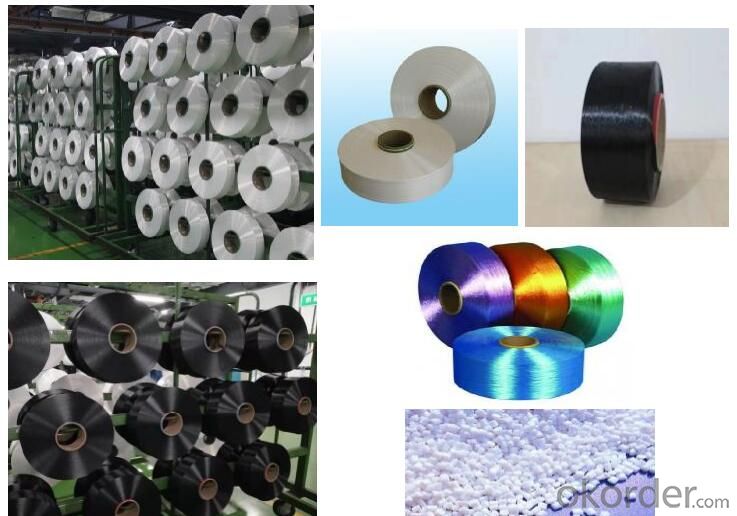

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

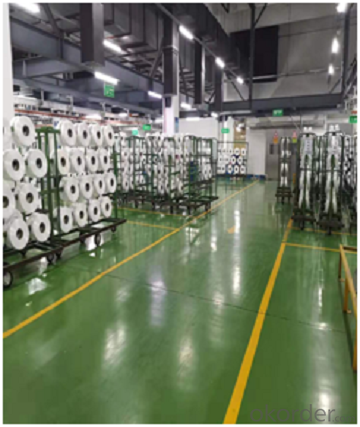

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Advantage of Us:

1. Subsidiary of Stated-owned group, reliable and trustable

2. Industry leader in the PET chip and yarn fields

3. On time delivery and prompt response

4. Well-funded and accept different kinds of payment terms

- Q: What is the difference between textile sizing and paper making?

- The modified starch used in papermaking is mainly: acid modified starch (surface sizing), oxidized starch (surface sizing, coating), phosphate starch (surface sizing, coating), oxidized acetate starch (coating) Cationic starch, amphoteric starch (pulp added), grafted starch (coated. Market less) a technology is not up to standard, and then a cost can not accept

- Q: There are several yarns of textile mills

- In the special yarn: in the special yarn 21 to 32 special (British 19 to 28 British branch) of the yarn. Such yarns are suitable for medium and thick fabrics such as medium cloth, gabardine, khaki and so on. 3. Fine yarn: fine yarn refers to 11 to 20 special (British 29 to 54 British branch) of the yarn. Such yarns are suitable for thin fabrics, such as fine cloth, poplin and the like. 4. Special fine yarn: special fine yarn refers to 10 special and below (British 58 British branch and above) of the yarn.

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- At a nominal moisture regain, a 1-pound (453, 5g) heavy yarn length of 840 yards (one yard equal to 0,9144 m) is a multiple of 1 pound, which is just 840 yards long, ; 1 pound yarn length of 21 × 840 yards long, the fineness of the yarn 21, written for 21s

- Q: How to choose the twist of the roving?

- The roving strength increases with the increase of the roving coefficient, and the roving twist factor is increased to reduce the production efficiency of the roving machine, but it can increase the strength of the roving, reduce the roving elongation and improve the quality of the roving.

- Q: Textile class 21 yarn, 32 shares of what is the meaning of goods ah

- Such as the yarn, 21 is a single yarn, 32 shares, equivalent to 16 yarn. So 32 shares more than 21 single yarn to be thick. The yarn is also more expensive than the single yarn.

- Q: What is the reason why the yarn is spinning

- Jingwei yarn is naturally based on the geographical latitude and longitude of the call, horizontal called weft, parallel to the cloth called warp,

- Q: What is the difference between mesh cloth and Bali yarn?

- Balinese yarn, also known as glass yarn, English name voile, textile and apparel fabrics in a kind, is a plain weave woven thin transparent fabric, belonging to the woven fabric.

- Q: What are the types of textile yarns?

- Raw yarn (unprocessed): UDY (no extension) POY (semi-extended) FOY (full extension), processing wire, spinning, packing yarn, yarn number of shares: single strand

- Q: Forming Principle of Yarn of Textile Industry

- Steel ladder in the older models is completed by iron cannon, that is, a designed iron arc to guide the steel lift, a bit similar to the cam mechanism. But now some new models, such as 1502, there are special molding agencies, I think it should be computer control, and is a separate variable frequency motor drag

- Q: What is the yarn in the textile

- The naked eye can be seen, generally can be hand picked out, but some of the fabric organization is not to pick, specifically to try their own.

Send your message to us

Fully Drawn Yarn FDY Yarn High Strength Eco-Friendly

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords