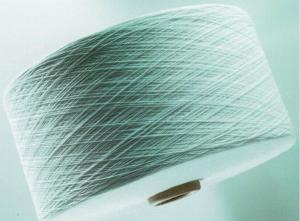

100% Water Soluble Sewing Thread Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100% Water Soluble Sewing Thread Made in China

Brife introduce:

Water-solubel PVA yarn

1) reasonable price

2) high quality

3) customized

5) payment: T/Tor L/C

Specs:

| Product name | 100 PVA yarn |

| Material | 100% whalen |

| Yarn type | spun yarn |

| Pattern | raw white |

| Style | ring spun yarn |

| Techniques | ring spun, siro spun or siro compact spun |

| Feature | Eco-Friendly, heat resistance, alkali-resistance, Moisture-Absorbent, |

| Use | Knitting, Weaving |

| payment | 100%TT T/T 30 in prepayment and the balance should be paid upon the copy of B/L, L/C at sight |

| Twistness | bellow 330 for knitting, above 380 for weaving |

| Yarn count | 20S-70S and 2-ply |

| package | 1, usually pp bags packing, 25kgs per bag , 320 bags /one 20'container (8tons) 2, also supply carton packing, 40kgs per carton, 150 carton / one 20' container (6tons) 3, also pallet packing 4, according to customers'needs |

We can supply water soluble yarn, 20 degree to 90 degree, yarn counts are from 20s to 100s.

This is a new kind of environmental friendly product. It can be mainly used for making towels,socks, the top-grade gloves, etc.

It can be used to make the untwist yarn with the cotton yarn.

We are the manufacture, we export the pva yarns to India, Turkey, Pakistan,etc. Have a large market, If you have any requirment, please feel free to contact us.

PVA yarn: 20/40/70/80/90 degree

Ne 20s/1 40s/1 50s/1 60s/1 80s/1 100s/1

hot water soluble yarn use the China Sinopec pva fiber .

Cold water soluble yarn use the Japan pva fiber .

Sample delivery:

- Q: How does textile twist yarn identify?

- Therefore, in the detection of the composition of the textile, we can extract several from the fabric edge of the warp and weft, untwisted to form a loose as a sample, on the fire burning

- Q: Textile waste silk (abandoned side yarn) what purpose ah?

- Textile industry more and more waste, need to use. The rapid development of chemical fiber industry, for the development of non-woven technology provides a wealth of raw materials, broaden the possibility of product development. Many traditional textiles for the final application, targeted poor

- Q: What is the difference between textile sizing and paper making?

- Modified starch is currently used industrially, mainly acid modified starch, oxidized starch, phosphate starch, acetate starch, carboxymethyl starch, cationic starch, amphoteric starch, grafted starch.

- Q: There are several kinds of yarn in textile mill

- Many varieties of yarn, different performance. It can be made of natural fibers or a variety of chemical short fibers made of pure spinning, it can be mixed by several fibers made of blended yarn, but also by the chemical fiber directly from the filament yarn processing

- Q: Textile spinning workshop car car summary and plan

- Summary must have a brief overview of the situation and narrative, some relatively simple, some more detailed. Achievements and shortcomings. This is the main content of the summary. The purpose of the summary is to be sure to score and find out the shortcomings. What are the results, how big, what aspects of performance, how to obtain; the number of shortcomings, in what areas, how to produce, should be written clearly.

- Q: What are the types of cotton yarns?

- According to the roughness habits: ① coarse yarn: 17 "special" (tex) and the following cotton yarn are coarse yarn. Mainly used for weaving thick or velvet, from the cotton fabric, such as coarse cloth, velvet, solid, etc .; ② in the yarn: 18-27 cotton yarn in the yarn, for weaving flat cloth, twill, satin and other general Woven fabric; ③ fine yarn: 28 and above cotton yarn, used for weaving fine cloth poplin, high-grade needle, woven fabric.

- Q: Textile yarn 75d ppt memory silk how much money meal?

- Memory is the shape of memory fibers. Fabric gloss soft and bright, anti-crepe shrinkage performance is good, there are wicking perspiration and anti-ultraviolet function

- Q: Cotton cotton yarn consumption of cotton how much?

- Tons of yarn consumption of cotton "and the raw material grade and length and with the rate, equipment, technology, operation, and even with the spinning branch (Turks) and the workshop temperature and humidity are related to the amount of cotton consumption quota is as follows:

- Q: What is the diameter of a yarn of 40 yarns?

- Where 0.040 is the common diameter coefficient of the medium cotton yarn; if the high diameter cotton yarn (fine cotton yarn) is the common diameter coefficient is 0.037; this coefficient can be based on the yarn volume specific gravity (g / C㎡) formula.

- Q: Is the thickness of the yarns 40S and 80S / 2 in the textile fabric the same?

- If your cloth with the yarn is 80S / 2, you want to use 40S instead, the textile industry people can see at a glance, careful consideration.

Send your message to us

100% Water Soluble Sewing Thread Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords