FRP Pultrusion Profiles with Excellent Electromagnetism Property - Latest Styles Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

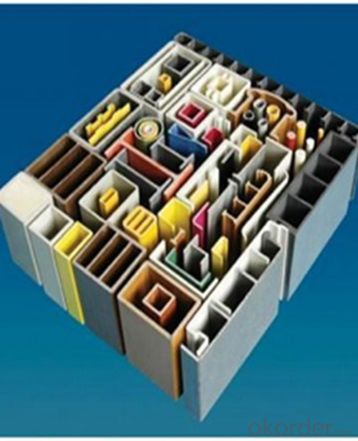

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Are FRP pultrusion profiles resistant to alkaline substances?

- Yes, FRP pultrusion profiles are generally resistant to alkaline substances. The use of fiberglass reinforced polymer (FRP) in pultruded profiles provides excellent resistance to a wide range of chemicals, including alkaline substances. The resin used in the manufacturing process is typically a thermosetting polymer, such as polyester or vinyl ester, which offers high resistance to alkaline solutions. Moreover, the reinforcement of fiberglass imparts additional strength and durability to the profiles, making them highly resistant to corrosion and degradation from alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the specific resin formulation and manufacturing process. Therefore, it is recommended to consult with the manufacturer or supplier to ensure the profiles meet the desired resistance requirements for specific alkaline environments.

- Q: What are the characteristics of FRP products?

- Light high-strengthThe relative density is between 1.5~2.0 and only 1/4~1/5 of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, while the specific strength can be compared with that of advanced alloy steel. As a result, aviation, rockets, aerospace vehicles, high pressure vessels, and other applications that need to reduce weight have excellent results. The tensile, flexural and compressive strengths of some epoxy FRP can reach over 400Mpa.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

- Q: Can FRP pultrusion profiles be used in the construction of elevated walkways?

- FRP pultrusion profiles have the capability to be utilized in the construction of elevated walkways. These profiles are not only lightweight, but they also possess significant strength, rendering them an optimal selection for the creation of walkways that are durable and have longevity, even when subjected to heavy foot traffic. Additionally, they provide exceptional resistance to corrosion, making them suitable for outdoor applications where exposure to moisture, chemicals, and UV radiation is a concern. Moreover, due to their high strength-to-weight ratios, FRP pultrusion profiles can be easily installed and lessen the structural load on the supporting elements. Furthermore, the non-conductive nature of FRP profiles make them a safer alternative for walkways in areas that are prone to electrical hazards. In summary, the advantages offered by FRP pultrusion profiles make them highly suitable for the construction of elevated walkways.

- Q: Are FRP pultrusion profiles impact resistant?

- FRP pultrusion profiles are widely recognized for their exceptional impact resistance. By combining reinforcing fibers like glass or carbon with a polymer matrix, they become intrinsically sturdy and long-lasting. The pultrusion process further bolsters their impact resistance by aligning the fibers in the direction of the load, providing optimal strength against impacts. Additionally, these profiles boast a remarkable strength-to-weight ratio, enabling them to withstand heavy impacts without significant damage or deformation. This characteristic makes them ideal for industries like construction, transportation, and infrastructure, where impact resistance is vital. Furthermore, FRP pultrusion profiles exhibit outstanding resistance to corrosion, chemicals, and UV radiation, enhancing their durability and long-term performance. Even in harsh environments, they maintain their impact resistance properties, making them the preferred choice for various sectors. Nonetheless, it is crucial to acknowledge that the impact resistance of FRP pultrusion profiles can vary depending on factors like design, composition, and manufacturing process. To ensure the profiles meet the desired impact resistance requirements for a specific application, it is advisable to consult with the manufacturer or supplier.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to sulfuric acid. The corrosion resistance of FRP profiles is one of their key advantages compared to traditional materials like steel or concrete. Sulfuric acid is a highly corrosive substance, but FRP pultrusion profiles can withstand its effects due to the inherent properties of the composite materials used in their construction. The corrosion resistance of FRP profiles is mainly attributed to the resin matrix that encapsulates the reinforcing fibers. Most commonly used resins in pultrusion, such as polyester, vinyl ester, or epoxy, have excellent chemical resistance properties, including resistance to sulfuric acid. However, it is important to note that the resistance of FRP pultrusion profiles to sulfuric acid can vary depending on several factors. The concentration and temperature of the acid, as well as the specific resin formulation used in the profile, can influence the overall resistance. In highly concentrated or elevated temperature environments, it is advisable to consult with the manufacturer or supplier to ensure the specific FRP profile meets the required resistance level. In general, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them suitable for various applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

- Q: What types of materials are commonly used in FRP pultrusion?

- Commonly used materials in FRP pultrusion include fiberglass, polyester resin, vinyl ester resin, epoxy resin, carbon fiber, and aramid fiber.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in pharmaceutical manufacturing. FRP profiles are made by impregnating fibers with a resin matrix, typically polyester or vinyl ester, which provides excellent chemical resistance. These profiles are designed to withstand exposure to a wide range of chemicals including acids, alkalis, solvents, and various cleaning agents commonly used in pharmaceutical manufacturing processes. The combination of the fiber reinforcement and the chemical-resistant resin matrix makes FRP pultrusion profiles an ideal choice for applications where exposure to aggressive chemicals is a concern. Unlike traditional materials like steel or wood, FRP profiles do not corrode or react chemically with the substances they come into contact with. Furthermore, FRP pultrusion profiles offer several other advantages for pharmaceutical manufacturing applications. They have exceptional strength-to-weight ratio, are non-conductive, and have high mechanical resistance. Additionally, FRP is a non-porous material, preventing the absorption or release of chemicals, which is crucial for maintaining strict hygiene and avoiding contamination in pharmaceutical processes. Overall, FRP pultrusion profiles are a reliable and durable choice for pharmaceutical manufacturing environments, providing excellent resistance to the chemicals commonly used in these processes.

- Q: Can FRP pultrusion profiles be used in the construction of swimming pool enclosures?

- Swimming pool enclosures can make use of FRP pultrusion profiles, which are known for their excellent strength-to-weight ratio, corrosion resistance, and durability. This makes them an ideal choice for outdoor applications like swimming pool enclosures. To manufacture FRP pultrusion profiles, fiberglass rovings are pulled through a resin bath and then through a heated die. This results in a continuous profile of uniform shape and strength. This manufacturing process ensures that the profiles are strong, stiff, and lightweight, making them easy to handle and install. In the construction of swimming pool enclosures, FRP pultrusion profiles can be utilized for various structural elements such as beams, columns, trusses, and panels. These profiles provide the necessary strength and support, while also offering resistance to corrosion, moisture, and UV radiation, which are common challenges in a swimming pool environment. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and aesthetically pleasing swimming pool enclosures. They can be fabricated in different shapes, sizes, and colors, enabling the desired architectural look and feel. Overall, FRP pultrusion profiles offer a reliable and long-lasting solution for constructing swimming pool enclosures. They provide the necessary strength, durability, and resistance to environmental factors. Additionally, their lightweight nature simplifies handling and installation, ultimately reducing construction time and costs.

- Q: What are the limitations of using FRP pultrusion profiles?

- There are several limitations associated with using FRP (Fiber Reinforced Polymer) pultrusion profiles, which are worth considering when selecting materials for a particular application. 1. Limited design flexibility: FRP pultrusion profiles are manufactured through a continuous process, resulting in a fixed cross-sectional shape. This restricts the ability to create complex or custom profiles, limiting design flexibility compared to other materials like metals or plastics. 2. Vulnerability to UV degradation: FRP materials can be susceptible to degradation when exposed to ultraviolet (UV) radiation. Over time, prolonged exposure to sunlight can cause fading, discoloration, and loss of mechanical properties. Therefore, proper surface coatings or UV protection measures must be implemented to ensure long-term durability in outdoor applications. 3. Lower impact resistance: FRP pultrusion profiles generally have lower impact resistance compared to metals. While they offer excellent strength-to-weight ratios, they may be more prone to damage from impacts or heavy loads. Careful handling and structural reinforcement may be necessary to mitigate the risk of damage. 4. Thermal expansion and contraction: Like most polymers, FRP materials have a relatively high coefficient of thermal expansion compared to metals. This means that they will expand and contract more significantly with changes in temperature. This property must be accounted for in design calculations and proper allowances made to ensure dimensional stability and prevent issues such as buckling or warping. 5. Limited fire resistance: FRP pultrusion profiles are generally combustible and can contribute to the spread of fire. While some FRP materials can be formulated with fire-retardant additives, they may still not meet the stringent fire safety requirements of certain applications. In situations where fire resistance is critical, alternative materials with better fire resistance properties may be preferred. 6. Cost considerations: FRP pultrusion profiles, especially those with specialty reinforcements or additives, can be more expensive compared to traditional materials like steel or aluminum. While the initial material cost may be higher, it is important to consider the overall life cycle cost, including maintenance, durability, and weight savings, to determine the cost-effectiveness of FRP profiles for a specific application. It is essential to carefully evaluate these limitations and compare them against the specific requirements and constraints of the intended application to determine whether FRP pultrusion profiles are the most suitable materials to use.

Send your message to us

FRP Pultrusion Profiles with Excellent Electromagnetism Property - Latest Styles Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords