FRP Pultrusion Profiles Molded Gratings - Fiberglass & Plastic Grating Floors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

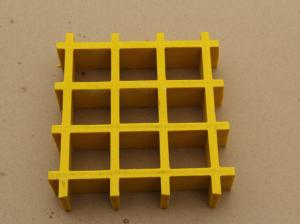

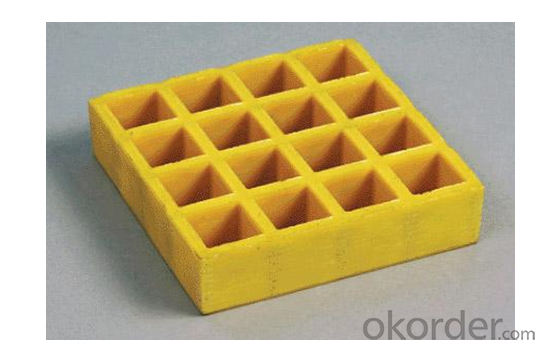

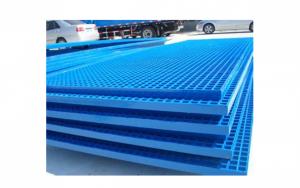

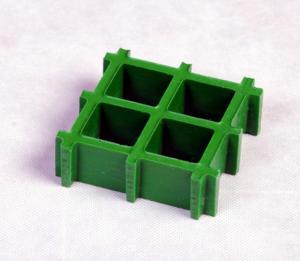

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Aging Resistance

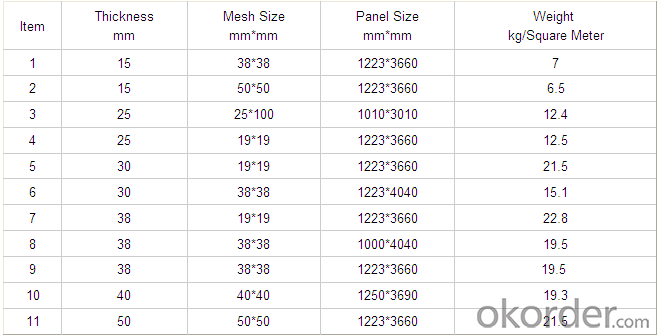

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

easy installation

Application

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

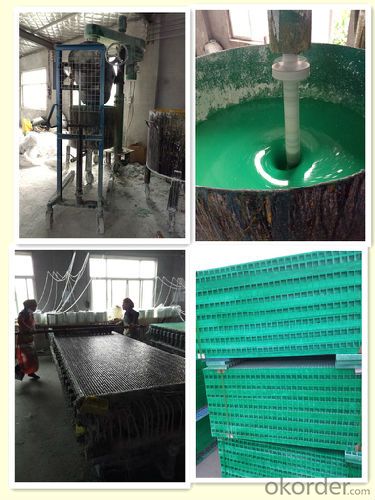

PROCESS

FACTORY

- Q: How do FRP pultrusion profiles perform in corrosive gas environments?

- FRP pultrusion profiles perform exceptionally well in corrosive gas environments due to their inherent resistance to corrosion. The composite materials used in their construction, such as fiberglass reinforcements and resin matrices, provide excellent protection against chemical attack and degradation. This makes FRP pultrusion profiles a reliable choice for applications where exposure to corrosive gases is a concern.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in pharmaceutical manufacturing. The use of high-quality resins and fiberglass reinforcement in the manufacturing process makes FRP pultrusion profiles highly resistant to a wide range of chemicals, acids, and alkalis commonly used in pharmaceutical manufacturing. However, it is always advisable to consult with the manufacturer or supplier to ensure that the specific chemicals used in the manufacturing process are compatible with the FRP profiles.

- Q: How do FRP pultrusion profiles perform in extreme humidity conditions?

- FRP pultrusion profiles perform exceptionally well in extreme humidity conditions. The fiberglass-reinforced plastic material used in the profiles is highly resistant to moisture absorption, preventing any degradation or dimensional changes. This makes them ideal for applications in humid environments, as they maintain their strength, durability, and structural integrity over time.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of pedestrian bridges. FRP pultrusion profiles offer several advantages that make them suitable for bridge construction. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in pedestrian bridges where weight considerations are important. The lightweight nature of FRP profiles also makes transportation and installation easier and more cost-effective. Secondly, FRP pultrusion profiles are corrosion-resistant, which is a crucial factor in bridge construction. Unlike traditional materials like steel or concrete, FRP does not rust or corrode, even in harsh environmental conditions. This property significantly extends the lifespan of the pedestrian bridge and reduces maintenance costs. Additionally, FRP pultrusion profiles offer design flexibility. They can be easily customized to meet specific project requirements, allowing for unique and innovative bridge designs. The material can be molded into various shapes and sizes, enabling the construction of aesthetically pleasing pedestrian bridges. Furthermore, FRP pultrusion profiles have excellent mechanical properties, including high strength-to-weight ratio and fatigue resistance. This ensures that the bridge can withstand the loads and stresses imposed by pedestrian traffic over an extended period. Lastly, FRP pultrusion profiles are non-conductive, making them a safe choice for pedestrian bridges. They do not conduct electricity, which reduces the risk of electrical accidents in areas where overhead power lines or electrical equipment are present. In conclusion, FRP pultrusion profiles are a suitable choice for the construction of pedestrian bridges due to their lightweight, corrosion-resistant, customizable, and mechanically strong properties. Their use can result in durable, low-maintenance, and visually appealing bridges that provide a safe and efficient means of pedestrian transportation.

- Q: What is the torsional strength of FRP pultrusion profiles?

- The torsional strength of FRP (Fiber Reinforced Polymer) pultrusion profiles is determined by various factors including the type and arrangement of fibers, resin matrix, manufacturing process, and the overall design of the profile. FRP pultrusion profiles are typically designed to have high torsional strength due to the inherent properties of the composite materials used. The torsional strength of FRP pultrusion profiles can vary depending on the specific application and the desired performance requirements. Manufacturers often conduct extensive testing to determine the torsional strength of their profiles and provide relevant data to customers. FRP pultrusion profiles are known for their excellent torsional strength compared to traditional materials like steel or aluminum. The combination of high-strength fibers and a durable resin matrix allows FRP profiles to withstand significant torsional forces without experiencing permanent deformation or failure. It is important to note that the torsional strength of FRP pultrusion profiles can be customized to meet specific project requirements. By adjusting the fiber type, fiber orientation, resin system, and profile geometry, manufacturers can optimize the torsional strength to ensure that the profiles can withstand the anticipated loads and operational conditions. In summary, the torsional strength of FRP pultrusion profiles is generally high due to the unique properties of the composite materials used and can be further customized to meet specific application requirements.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

- Q: What are the insulation properties of FRP pultrusion profiles?

- FRP pultrusion profiles have excellent insulation properties due to the nature of the materials used in their composition. FRP, which stands for Fiber Reinforced Polymer, combines the strength of the fiber reinforcement with the insulating properties of the polymer matrix. The insulation properties of FRP pultrusion profiles are primarily determined by the polymer matrix, which is typically made of thermosetting resins such as polyester, vinyl ester, or epoxy. These resins have low thermal conductivity, meaning they are poor conductors of heat. This property allows FRP pultrusion profiles to effectively reduce heat transfer through conduction. In addition to low thermal conductivity, FRP pultrusion profiles also exhibit excellent electrical insulation properties. The polymer matrix acts as an insulator, preventing the flow of electric current and reducing the risk of electrical accidents or damage to equipment. Furthermore, FRP pultrusion profiles are also resistant to moisture, chemicals, and UV radiation, which further enhances their insulation properties. Moisture and chemicals can degrade the insulation properties of materials, but FRP is highly resistant to these factors, ensuring long-term insulation performance. Overall, FRP pultrusion profiles offer superior insulation properties, making them an ideal choice for applications where thermal or electrical insulation is required. They provide a reliable and durable solution for various industries, including construction, electrical, and transportation.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the transportation and logistics industry. FRP pultrusion profiles offer several advantages that make them suitable for various applications in this industry. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in transportation vehicles, such as trucks, trailers, and containers, where reducing weight is crucial for improving fuel efficiency and reducing emissions. Despite their lightweight nature, FRP pultrusion profiles can withstand heavy loads and harsh environmental conditions, ensuring their reliability and longevity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials, such as steel or aluminum, FRP does not rust or corrode when exposed to moisture or chemicals. This makes FRP profiles suitable for use in transportation and logistics applications that involve exposure to corrosive substances, such as saltwater, chemicals, or acidic environments. By using FRP pultrusion profiles, companies can reduce maintenance costs associated with corrosion and prolong the lifespan of their equipment. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of transportation and logistics applications. Whether it is for structural components, platforms, flooring, or supports, FRP profiles can be customized to fit different needs, ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. In the transportation and logistics industry, this can be beneficial for applications such as insulation for refrigerated containers or electrical insulation for specialized vehicles. In summary, FRP pultrusion profiles are well-suited for the transportation and logistics industry. Their lightweight, strong, durable, corrosion-resistant, and customizable nature, along with their electrical and thermal insulation properties, make them a reliable choice for various applications in this sector.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in mining operations. FRP materials are known for their excellent chemical resistance properties, making them suitable for various corrosive environments, including mining operations. The resin matrix used in FRP pultrusion profiles can be selected to provide resistance against a wide range of chemicals commonly found in mining applications, such as acids, alkalis, solvents, and corrosive gases. Additionally, the reinforcement fibers, usually made of glass or carbon, further enhance the overall chemical resistance of the profile. Furthermore, FRP pultrusion profiles are non-conductive, which makes them an ideal choice for electrical and mining applications. They do not corrode or degrade under exposure to chemicals, ensuring durability and longevity in harsh mining environments. However, it is essential to consider the specific chemicals and concentrations used in mining operations. While FRP pultrusion profiles have excellent chemical resistance in general, prolonged exposure to extremely aggressive chemicals or high concentrations may require additional measures, such as selecting specific resin systems or surface coatings, to ensure optimal performance and longevity. It is advisable to consult with FRP manufacturers or experts to determine the best-suited materials for specific mining chemical environments.

- Q: Do FRP pultrusion profiles require any special tools for installation?

- Yes, FRP pultrusion profiles do require special tools for installation. These tools typically include saws for cutting the profiles to size, drills for creating holes, and adhesive application tools for bonding the profiles to the substrate. Additionally, specialized fasteners and brackets may be needed to secure the profiles in place. It is important to use these tools correctly to ensure a proper and secure installation of FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles Molded Gratings - Fiberglass & Plastic Grating Floors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords