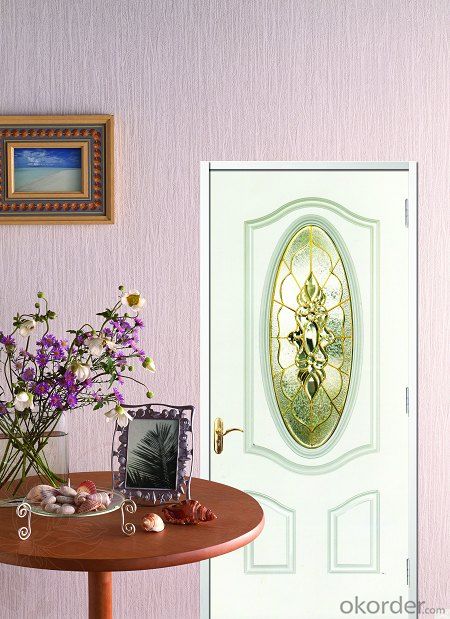

FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic/GRP Door-Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. Great apperance

2. High intensity

3. Long service life

4.Good sound insulation and heat preservation

5. Customize colors

Product Description

The Advantages of FRP Door &Window

Fiber-reinforced plastic (FRP) (also fiber-reinforced polymer) is compositematerialmading of polymermatrix reinforced with fiber. It’s commonly used inthe aerospace, automotive, marine etc. FRP has distinct advantages that makethem attractive for a wide uses. One of its uses is making FRP doors andwindows. The advantages are:

(1) Excellent water-sealing.Withrain-proof plate, grooves and poles water drainage, doors and windows canisolate rain to outside completely.

(2) Effectual heat preservation. The FRP doors and windows’ heat resistance is almost twice as much as plastic-steeldoors and windows. In winter, it’ll be good temperature keeper, increasing roomtemperature about 5°.

(3) High intensity. It could sustainits own weight, do not bend, fade, distort or rust.

(4)Perfect sound insulation.Withelaborate structure design and rigorous connection, the sound insulation of FRPdoors and windows is below 20db, which is in accordance with DIDN4109.

(5)Easy-maintained.FRP doors andwindows have good resistance to acids, alkalis and waste gas salty substances.They hardly need maintenance, any cleaner made them clean and new as before.

(6)High durability. FRP doors andwindows have long service life, about 50 years, almost same age with the building.

(7) We can customize any color or wooden grain according to your need.We will provide high-quality service, fast delivery and reasonable price,satisfying all your need.

comparing with other

FRP window and door Contrast to Other Materialswindow

Item | Aluminum alloy window /door | PVC window /door | FRP window /door | |

Weight | About 15kg/sq.m | About 8 kg/sq.m | About 6.2kgsq.m | |

Intensity | Tensile strength about 157MPa | Tensile strength about 49.2MPa | Tensile strength about 250MPa | |

Corrosion resistance | Intolerance Hydrogen Fluoride(HF) | Intolerance Hydrogen Fluoride(HF) | Excellent corrosion resistance | |

Insulativity | Good conductor, uninsulate | Have steel liner, bad insulativity | Good insulation and security | |

Durability | Service life less than 20 years. Frangibility | Service life less than 20 years. Frangibility | Service life more than 30 years. Durability | |

Cost | Cheap but high maintenance costs | Expensive and high maintenance costs | Reasonable price | |

Commonality | Over -20°C | -20°C-40°C, in high temperature easy to transfigure. | -40°C-80°C | |

Social benefits | High energy consumption, not environmentally-friendly window | Green product. | Green product |

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can certainly be used in renewable energy projects. FRP pultrusion profiles offer a wide range of advantages that make them suitable for various applications within the renewable energy sector. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for use in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus improving overall performance. Additionally, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in harsh environmental conditions. Secondly, FRP pultrusion profiles exhibit excellent corrosion resistance, making them suitable for solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period of time, reducing the need for frequent maintenance and replacement. Thirdly, FRP pultrusion profiles can be customized to meet specific project requirements, allowing for flexibility in design and functionality. They can be easily molded into complex shapes and sizes, enabling the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and have excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

- Q: Can FRP profiles replace carbon steel profiles?

- I am a man of glass fiber reinforced material. Honestly, "I can't do it."". Can be used in buildings, such as insulation, corrosion protection, aging resistance, flame retardant, etc.,

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles perform well in electrical grounding systems due to their non-conductive properties. Unlike metal profiles, FRP profiles do not carry electrical current, making them a safe and effective choice for electrical grounding applications. Additionally, FRP profiles are corrosion-resistant, durable, and lightweight, making them a reliable and long-lasting option for grounding systems.

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can definitely be used in the automotive industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP pultrusion profiles are lightweight, which is a crucial factor in the automotive industry as it helps in improving fuel efficiency and reducing overall vehicle weight. Lighter vehicles have lower energy consumption and emissions, making them more environmentally friendly. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratio. This means they can provide high strength and stiffness while being lightweight. This property makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. Furthermore, FRP pultrusion profiles are highly corrosion-resistant, which is a significant advantage in automotive applications. Vehicles are often exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP helps in ensuring the longevity and durability of automotive components, even in challenging environments. Additionally, FRP pultrusion profiles have good impact resistance, which is crucial for automotive safety. They can absorb and dissipate energy during impacts, reducing the risk of injury in case of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be designed to have specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the lightweight, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and prolonged component life, making them a viable alternative to traditional materials in automotive applications.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are corrosion-resistant. Water treatment plants are exposed to various corrosive elements, such as chemicals and moisture. Traditional materials like steel and concrete can deteriorate over time due to corrosion, leading to maintenance issues and potential structural failures. However, FRP pultrusion profiles are highly resistant to corrosion, ensuring long-term durability and reducing maintenance costs. Secondly, FRP pultrusion profiles are lightweight and have high strength-to-weight ratios. This makes them easy to handle and transport while maintaining structural integrity. Water treatment plants often require structural elements that can withstand heavy loads and support equipment. FRP pultrusion profiles provide the necessary strength without adding excessive weight, making them an ideal choice for such applications. Additionally, FRP pultrusion profiles are non-conductive and have excellent electrical insulation properties. This can be crucial in water treatment plants, where electrical equipment and wiring are present. The non-conductive nature of FRP helps prevent electrical hazards and ensures safe operation. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in design and construction. This adaptability makes FRP pultrusion profiles suitable for a wide range of applications within water treatment plants, including structural supports, walkways, handrails, and equipment enclosures. In summary, FRP pultrusion profiles are an excellent choice for the construction of water treatment plants due to their corrosion resistance, lightweight yet strong nature, electrical insulation properties, and customization options. They offer long-lasting durability, reduced maintenance costs, and enhanced safety, making them a reliable and efficient solution for this critical infrastructure.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Boat hulls can be effectively manufactured using FRP pultrusion profiles. These profiles possess numerous advantages that render them perfect for constructing boat hulls. Firstly, FRP pultrusion profiles are not only lightweight but also exceptionally sturdy and durable. Consequently, they are well-suited for boat hulls as their lightweight nature enhances fuel efficiency and enables increased speed. Moreover, their impressive strength-to-weight ratio guarantees that the boat can endure the rigors of the water without compromising its structural integrity. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion. This characteristic is of utmost importance for boat hulls, which are constantly exposed to water, salt, and other corrosive agents. The corrosion resistance of FRP pultrusion profiles ensures that the boat hull remains intact and maintains its performance over time, thus minimizing the need for frequent maintenance and repairs. Furthermore, FRP pultrusion profiles offer great design flexibility. They can be effortlessly molded into diverse shapes and sizes, thereby facilitating customization and optimization of boat hull designs. This flexibility empowers boat manufacturers to create hulls that are both functional and visually appealing. In addition to their strength, durability, corrosion resistance, and design flexibility, FRP pultrusion profiles also possess excellent electrical and thermal insulation properties. These properties are particularly important for boat hulls as they effectively prevent the passage of electrical currents and heat through the hull, thereby ensuring the safety and comfort of passengers and crew. Overall, FRP pultrusion profiles present an outstanding solution for boat hull manufacturing. Their lightweight, robust, and corrosion-resistant attributes, in conjunction with their design flexibility and insulation capabilities, make them an ideal choice for boat manufacturers seeking to produce high-performance and long-lasting vessels.

- Q: Can FRP pultrusion profiles be used in cooling towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in cooling towers. FRP pultrusion profiles offer several advantages that make them suitable for cooling tower applications. Firstly, FRP pultrusion profiles have excellent corrosion resistance, which is essential in a cooling tower environment where exposure to water and chemicals is common. Unlike traditional materials like steel, FRP pultrusion profiles do not rust or corrode, ensuring longer service life and reduced maintenance costs. Secondly, FRP pultrusion profiles have high strength-to-weight ratio, making them lightweight yet strong enough to withstand the structural requirements of cooling towers. This allows for easier installation and transportation, reducing overall project costs. Thirdly, FRP pultrusion profiles have excellent thermal insulation properties. Cooling towers involve the transfer of heat from water to the surrounding air, and the thermal insulation provided by FRP pultrusion profiles helps enhance the efficiency of the cooling process. Lastly, FRP pultrusion profiles are highly customizable and can be designed to meet specific requirements of cooling tower applications. They can be engineered to have various shapes, sizes, and dimensions to fit the specific needs of the cooling tower design. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for cooling tower applications, offering corrosion resistance, high strength-to-weight ratio, thermal insulation, and customization options.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- The renewable energy and solar power industry can effectively utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several key characteristics that make them ideal for such applications. To begin with, the high strength-to-weight ratio of FRP pultrusion profiles is crucial in the renewable energy sector. They are lightweight yet strong, allowing them to withstand various environmental conditions while remaining cost-effective. Additionally, these profiles offer excellent corrosion resistance, ensuring durability and longevity in outdoor and potentially corrosive environments like solar power plants or wind farms. Moreover, FRP pultrusion profiles have outstanding electrical insulation properties, making them suitable for electrical applications commonly found in the renewable energy industry. Furthermore, these profiles can be easily customized into various shapes and sizes, enabling the design and engineering of complex structures required for solar power installations or wind turbine blades. Furthermore, FRP materials are non-conductive and non-magnetic, ensuring their safety for use in electrical and magnetic fields associated with renewable energy systems. In conclusion, FRP pultrusion profiles provide a combination of strength, durability, lightweight, corrosion resistance, and electrical insulation properties that make them highly suitable for use in the renewable energy and solar power industry.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP pultrusion profiles can be used in the construction of offshore platforms. FRP, or fiber-reinforced polymer, offers excellent corrosion resistance, high strength-to-weight ratio, and durability, making it suitable for the harsh marine environment. These profiles can be customized to meet the specific requirements of offshore platforms, providing structural support and stability while minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic/GRP Door-Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords