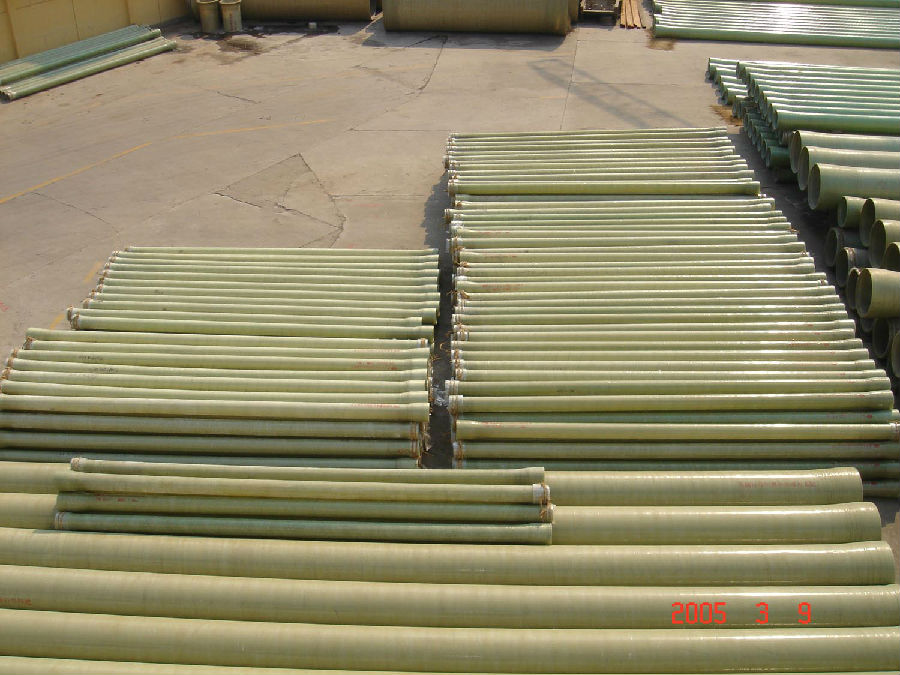

Composite Pipes - High Strength FRP/GRP Pipe for Water Transportation (DN<0.3m)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

In the FRP .with high tensile strength, the fiberglass plays the role of reinforcement whiles the wear-resistance and pressure –resistance synthetic resin is used for bonding the fiber as the basic materials. Putting together, they commonly play the role of being in finished form and load carrier.

Characteristics:

1. Good physical mechanics performance

2. Being resistant to chemical erosion and longer service life

3. Excellent hydraulic characteristics

4. Lower installation and keeping cost

5. Flexible design and shorter reform term

6. No medium pollution

FRP pipe classification by application field

1. Chemical medium transportation pipe

2.Various producing process pipe (chemical process, paper making process, polluted water treatment process, sea water purifying process, food and drink producing process, and medicine producing process)

3. Pressure pipe for small hydroelectric power station on the ground and cycling pipe for power plant

4. Polluted water collecting and transporting pipe

5. Drink water transporting main line and tubing pipe

6. Oil field water injecting pipe and oil transporting pipe

7. Heat transporting pipe and sea water transporting pipe

8. Agricultural irrigation pipe

9. FRP set (ventilation, air-conditioner, chimney, cleaner) and piping

10. Gas drainage pipe for mine

FRP pipe classification by pressure in working state

1. Medium and low pressure pipe 0.6MPa2.5 MPa

2. High pressure pipe5.5MPa24 MPa

3. Mobile gravity pipe (which can be used when the pressure is under 0.6MPa)

4. Vacuum tube, external pressure pipe or siphon.

FAQ:

1..Is your company a factory or trade company?

A:We have our own factory , we are on this business more than 10 years.

2.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

3.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q: What are FRP pipes made of?

- Length of single pipe lengthReduce pipe connection, speed up installation, improve the quality of the whole pipeline.

- Q: Do I need CCC certification for ventilated GRP?

- Of course, there is also used for air conditioning duct glass fiber reinforced plastic pipe, the thickness needs at least 25MM, lined with EPS insulation foam.

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- Not agree with the recommended answer, the same thickness of glass fiber reinforced plastic sand pipe and process tube, process tube stiffness is not low (can be calculated). The effect of sand inclusion is mainly to reduce the cost.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- It is generally assumed that it is made of glass fiber reinforced plastic. The main pipe is made of glass fiber reinforced plastic. The medium is corrosive. Other materials must not be suitable

- Q: What is the difference between glass tube, sand pipe and glass tube?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- Place an iron or glass piece of steel on a broken hole like a bicycle tire, then use three oil, two cloth, or five oil three cloth;

- Q: Slurry circulation glass fiber reinforced plastic pipe

- The slurry circulation glass fiber reinforced plastic pipe has good heat resistance and frost resistance. It can be used in the range of 40 to 80 degrees for a long time. If the resin is specially formulated, it can work at temperatures above 110 degrees celsius.

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Dislocation will cause the pipe to burst. The pressure is different, and the pipe will burst

- Q: What is the compressive strength of all kinds of FRP materials?

- Anti fouling and anti moth: unsaturated polyester resin surface clean and smooth, will not be ocean or sewage in the shellfish, fungi and other microorganisms stained, moth, so as to increase roughness, reduce water cross section, increase maintenance costs. FRP pipes are free from these pollution and are clean for a long time. At the same time, because of its smooth inner wall and excellent corrosion resistance, it will not cause scale and microbial growth, effectively guarantee water quality and maintain the stability of water resistance. But the traditional pipe still exist after water resistance increases and the surface fouling phenomenon.

- Q: What are FRP pipes used for making? What raw materials?

- Reinforced plastic made of glass fiber or its products as reinforcing material. Entitled "glass fiber reinforced plastics" or "glass fiber reinforced plastics". Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. Glass has a hard and brittle, has a good transparency and high temperature resistance, corrosion resistance and other properties; at the same time, steel is very hard and not brittle, but also has high temperature resistance characteristics.

Send your message to us

Composite Pipes - High Strength FRP/GRP Pipe for Water Transportation (DN<0.3m)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords