Forklifts - Heavy forklift - CPCD135B Forklift

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Electric forklifts - powered by lead-acid batteries, several types of forklifts are electric: cushion tire forklifts, scissor lifts, order pickers, stackers, reach trucks and pallet jacks. Electric forklifts are primarily used indoors on flat, even surfaces. Electric forklift batteries last 6 consecutive hours or throughout an 8-hour shift with 2-3 breaks. Batteries prevent the emission of harmful fumes and are recommended for facilities in food-processing and healthcare sectors.

Fuel cell forklifts produce no local emissions, can work for a full 8-hour shift on a single tank of hydrogen, can be refueled in 3 minutes and have a lifetime of 8–10 years. Fuel-cell-powered forklifts are often used in refrigerated warehouses as their performance is not degraded by lower temperatures.

Guided Very Narrow Aisle Order Picking truck - counterbalance type Order Picking Truck similar to the Guided Very Narrow Aisle truck, except that the operator and the controls which operate the machine are in a cage welded to the mast. The operator of course wears a restraint system to protect him against falls. Otherwise the description is the same as Guided Very Narrow Aisle truck.

Truck Mounted Forklift / Sod Loader - comes in Sit Down Center Control. Usually has an Internal Combustion Engine. Engines are almost always diesel, but sometimes operate on kerosene, and sometimes use propane injection as a power boost. Some old units are two stroke compression ignition, most are four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems.

Cost

The cost of a new forklift can vary between $15,000 to in excess of $150,000, dependent on the model and in particular the capacity of the forklift. The most common forklifts are typically gas powered and have a capacity of between 2 and 2.5 tonnes. The cost of these varies from around $18,500, for some of the less well known Chinese manufactured forklifts, up to around $20,000, for the German forklifts from well established manufacturers; it is important to take into account fuel and maintenance costs when calculating the total cost of ownership.

Specialty trucks

At the other end of the spectrum from the counterbalanced forklift trucks are more 'high end' specialty trucks:

Articulated Counterbalance Trucks

These are, unlike most lift trucks, front wheel steer, and are a hybrid VNA (Very Narrow Aisle) truck designed to be both able to offload trailers and place the load in narrow aisle racking. Increasingly these trucks are able to compete in terms of pallet storage density, lift heights and pallet throughput with Guided Very Narrow Aisle trucks, while also being capable of loading trucks, which VNA units are incapable of doing.

Guided Very Narrow Aisle Trucks

These are rail or wire guided and available with lift heights up to 40' non-top-tied and 98' top-tied. Two forms are available; 'man-down' and 'man-riser' where the operator elevates with the load for increased visibility or for multilevel 'break bulk' order picking. This type of truck, unlike Articulated Narrow Aisle Trucks, requires a high standard of floor flatness.

Omni-directional Trucks

Omni-directional technology (such as Mecanum wheels) can allow a forklift truck to move forward, diagonally and laterally, or in any direction on a surface. Omni-directional wheel system is able to rotate the truck 360 degrees in its own footprint or strafe sideways without turning the truck cabin. One example is the Airtrax Sidewinder. This forklift truck has also made an appearance in the TV -series called 'Mythbusters'.

Forklift Specification:

| MODEL | CPCD135B | ||||

| PERFORMANCE DATA | rated capacity | kg | 13500 | ||

| load centre | mm | 600 | |||

| mast type | stage | 2-CJ | |||

| max lifting height | mm | A | 4000 | ||

| overall height | lifting | mm | E | 5884 | |

| lowering | mm | F | 3884 | ||

| free lift height | mm | 0 | |||

| mast inclination(F/B) | * | O/P | 6\12 | ||

| fork length | mm | M | 1500 | ||

| PERFORMANCE DATE | lifting speed | loaded | mm/s | 290 | |

| unloaded | mm/s | 310 | |||

| lowering speed | loaded | mm/s | < 600 | ||

| unloaded | mm/s | >300 | |||

| travelling speed | loaded | km/h | 25 | ||

| unloaded | km/h | 27 | |||

| min.turning radius | mm | B | 4160 | ||

| min.width of angle aisle | mm | 3620 | |||

| brake distance | m | < 7 | |||

| max.gradient | % | 15 | |||

| overall length | mm | C | 6030 | ||

| overall width | mm | D | 2460 | ||

| overall height(over head) | mm | G | 2875 | ||

| wheelbase | mm | H | 3100 | ||

| SIZE WEIGHT | track | front | mm | I | 1765 |

| rear | mm | J | 1890 | ||

| min-gound clearance | mm | 260 | |||

| service weight | 17500 | ||||

| BRAKE | brake operation type | driving brake | AIR-BOOST TYPE | ||

| parking brake | shde-drum type | ||||

| ENGINE | model | 6DE1-24 | |||

| manufacturer | DACHAI | ||||

| transimission type | Hydraulical | ||||

| Other | tyre(pneumatic) | front | 12.00-20-18PR | ||

| rear | 12.00-20-18PR | ||||

| Carriage type | trunk welding type | ||||

| truck stability | conform to standard JB/SQ131-90 | ||||

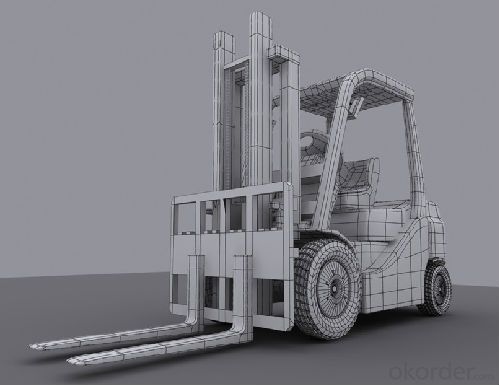

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: How to solve the oil spill?

- Fix the main bearing in time. When the main bearing and shaft neck fit clearance is too large, before and after the sealing of the oil seal for crankshaft impact could lose caused by the oil from the crankshaft head leakage, or to the penetration of the clutch oil, thus pollution lining cause skid, job failure. Avoid the one-way valve and the ventilatory valve. This type of valve hole blocking easy cause box shell temperature, pressure, piston motion resistance, fuel consumption increase, oil and gas is full of the whole space, lubricating oil consumption increase and change cycle shortened. Properly handle all kinds of tubing joint seals. Tighten and press the nuts to seal and seal, after sealing or sealing the thin copper leather on two cones. Avoid hubcaps. Cavity should be adopted for the lubrication (namely adequate lubrication), dredge vent, the rational use of braking, strictly choose the high quality parts, and assembly and adjustment according to the process specification. Hopefully, the above points will help you to solve similar problems.

- Q: What certificate is required to train the forklift

- A copy of the id card, two on the back. There are four photos of the white background, the body check. The application form. The technical supervision department of jiangmen city is aimed at the person who can open, the examination certificate. Will not drive, still go to zhongshan city east feng town sha kou bridge, yi lake peninsula south gate seek li coach to learn. With the study, learn the textual research. He that learns well is fast

- Q: Which is better, solid forklift tyres and inflatable forklift tyres?

- Cons: tires are harder and harder to bump Like, the installation is troublesome, the process is much, if the installation is not good still can cause the tyre and the rim to skid.

- Q: How many ways to push the forklift truck?

- Fuel and electric power. The fuel oil tonnage is big, the power foot, because the burning oil will produce the exhaust gas to the environment the high place is not suitable for use! The relative tonnage of electric power is small, suitable for a small warehouse or clean workshop.

- Q: What about the steering wheel of an electric forklift without stepping on the accelerator?

- Do you have an electric drive or a hydraulic steering? If the oil pressure is turned, will the rise and tilt be normal? If the machine is normal, check the multi-way valve if it is not normal

- Q: What are the requirements for a forklift

- To apply for a job: Older than 18 years of age; A healthy body Have certain level of culture and work experience; Knowledge and skills in the safety and technology of the special equipment operators with forklift license;

- Q: Is the forklift card issued by the labor bureau or the bureau of quality supervision? Which good?

- Forklift license has two kinds: 1. Grade card is issued by the labor bureau skills (primary, intermediate, advanced) the certificate of cover different grade card is different color, green, primary, intermediate and senior red, blue. Such certificates may be subsidized by the title of office; The certificate of special operations issued by the bureau of quality supervision is the same as that of green skin, which can be used for forklift operation. The more important.

- Q: Why is the front wheel of the forklift narrow

- The rear wheel is smaller, so the needed floor area is smaller and the radius becomes smaller, making the shift more flexible.

- Q: What do you mean by the center spacing of the load on an electric forklift?

- Load center distance In short, it means the center of gravity of the cargo. For example, the length of the fork is one meter, and the center of the load is half a meter away. In turn, the 1.8-meter-long cargo fork, the center of the payload is 0.9 meters away. It is dangerous to use a one-meter fork fork, which is 1.8 meters long, and the center of mass of the cargo is at 0.9 meters. It's likely to fall!

- Q: What procedures are required for a forklift licence

- The forklift should be known Number one: you need information for the inspection (2) inspection of motor vehicles in the factory Certificate of forklift (original and copy of each) A copy of the owner's code certificate A copy of the business license of the owner It is not directly handled by the legal person (which is required to submit a power of attorney)

Send your message to us

Forklifts - Heavy forklift - CPCD135B Forklift

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords