Forklifts - Heavy forklift - FD200B forklift

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Articulated Counterbalance Trucks

These are, unlike most lift trucks, front wheel steer, and are a hybrid VNA (Very Narrow Aisle) truck designed to be both able to offload trailers and place the load in narrow aisle racking. Increasingly these trucks are able to compete in terms of pallet storage density, lift heights and pallet throughput with Guided Very Narrow Aisle trucks, while also being capable of loading trucks, which VNA units are incapable of doing.

Guided Very Narrow Aisle Trucks

These are rail or wire guided and available with lift heights up to 40' non-top-tied and 98' top-tied. Two forms are available; 'man-down' and 'man-riser' where the operator elevates with the load for increased visibility or for multilevel 'break bulk' order picking. This type of truck, unlike Articulated Narrow Aisle Trucks, requires a high standard of floor flatness.

Omni-directional Trucks

Omni-directional technology (such as Mecanum wheels) can allow a forklift truck to move forward, diagonally and laterally, or in any direction on a surface. Omni-directional wheel system is able to rotate the truck 360 degrees in its own footprint or strafe sideways without turning the truck cabin. One example is the Airtrax Sidewinder. This forklift truck has also made an appearance in the TV -series called 'Mythbusters'.

A straight mast container handler at Haikou Xiuying Port, Hainan, China

UL 558 Safety Rated Trucks

In North America, some internal combustion powered industrial vehicles carry Underwriters Laboratories ratings that are part of UL 558. Industrial trucks that are considered "safety" carry the designations GS (Gasoline Safety) for gasoline powered, DS (Diesel Safety) for diesel powered, LPS (Liquid Propane Safety) for liquified propane or GS/LPS for a dual fuel gasoline/liquified propane powered truck.

UL 558 is a two-stage Safety Standard. The basic standard, which is G, D, LP, and G/LP is what Underwriter's Laboratories considers the bare minimum required for a lift truck. This is a voluntary standard, and there is no requirement in North America at least by any Government Agency for manufacturers to meet this standard.

The slightly more stringent GS, DS, LPS, and GP/LPS, or Safety standard does provide some minimal protection, however it is extremely minimal. In the past Underwriter's Laboratory offered specialty EX and DX safety certifications. If you require higher levels of protection you must contact your local Underwriter's Laboratory Office and check ask them what the correct safety standard is for your workplace.

UL 583 Safety Rated Trucks

UL 583 is the Electric equivalent of UL 558. As with UL 558 it is a two-stage standard.

Explosion proof trucks "EX RATED"

These are for operation in potentially explosive atmospheres found in chemical, petrochemical, pharmaceutical, food and drink, logistics or other industries handling flammable material. Commonly referred to as Pyroban trucks in Europe, they must meet the requirements of the ATEX 94/9/EC Directive if used in Zone 1, 2, 21 or 22 areas and be maintained accordingly.

U.S. Military 10K-AT "Adverse Terrain"

Automated forklift trucks

In order to decrease work wages, reduce operational cost and improve productivity, automated forklifts have also been developed.Automated forklifts are also called forked automated guided vehicles and are already available from a growing number of suppliers.

Counterbalanced forklift components

A typical counterbalanced forklift contains the following components:

Image of an electric forklift with component descriptions

Truck frame - is the base of the machine to which the mast, axles, wheels, counterweight, overhead guard and power source are attached. The frame may have fuel and hydraulic fluid tanks constructed as part of the frame assembly.

Counterweight - is a mass attached to the rear of the forklift truck frame. The purpose of the counterweight is to counterbalance the load being lifted. In an electric forklift the large lead-acid battery itself may serve as part of the counterweight.

Cab - is the area that contains a seat for the operator along with the control pedals, steering wheel, levers, switches and a dashboard containing operator readouts. The cab area may be open air or enclosed but it is covered by the cage-like overhead guard assembly. When enclosed, the cab may also be equipped with a cab heater for cold climate countries along with a fan or air conditioning for hot weather.

Forklift Specification:

| Model | Unit | FD200B | |

| Rated Capacity | kg | 20000 | |

| Lifting Height | mm | 4000 | |

| Load Centre | mm | 1250 | |

| Max.Height | Top | mm | 6470 |

| Down | mm | 4470 | |

| Mast Inclination(F/R) | * | 6\12 | |

| Fork | mm | 1800 | |

| Lifting Speed | loaded | mm/s | 330 |

| unloaded | mm/s | 340 | |

| Lowering Speed | loaded | mm/s | <600 |

| unloaded | mm/s | >300 | |

| Travel Speed | loaded | mm/s | 28 |

| unloaded | mm/s | 30 | |

| Min. Turning Radius | mm | 5500 | |

| Min.Width of Right Angle Aisle | mm | 4860 | |

| Brake Distance(unloaded) | m | <7 | |

| Max.Gradient | % | >20 | |

| Overall Length | mm | 8370 | |

| Overall width | mm | 3200 | |

| Overall Height (Overhead guard) | mm | 3585 | |

| Wheelbase | mm | 3750 | |

| Track | front | mm | 2350 |

| rear | mm | 2480 | |

| Min. Ground Clearance | mm | 305 | |

| Service Weights | kg | 31000 | |

| Brake Type | Driving Brake | HYDRAULIC TYPE | |

| Parking Brake | PLIERS PLATE TYPE | ||

| Engine | Model | TAD720VE | |

| Manufacturer | VOLVO | ||

| Transmision | Hydraulic | ||

| Tyre | front | pneumatic | 4X14.00-24-24PR |

| rear | pneumatic | 2X14.00-24-24PR | |

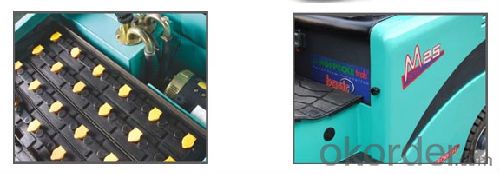

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

Forklift truck is an industrial handling vehicle, it is a kind of wheeled transport vehicle which is used for loading and unloading, stacking and short distance transportation.

The basic operation function of forklift is divided into horizontal handling, stacking, loading / unloading / pick and choose. According to the enterprise to achieve the operating function can be introduced from the above models in the initial determination. Also special operations will affect the forklift specific configuration, such as handling is roll and molten iron, need forklift installation is to perform a specific function.

Industrial handling vehicles widely used in ports, railway stations, airports, freight yards, factories, workshops, warehouses, distribution centers and distribution center, the pallet cargo loading and unloading, handling operations, it is essential to the tray transportation, container transport equipment in the cabin, car and container.

For indoor handling, such as in the warehouse, electric forklift more advantage. Compared with the internal combustion forklift, its main advantages are low noise, no pollution. Although the price of electric forklift forklift trucks than high, but low operation cost. Electric fork lift trucks are mainly due to no fuel, no need to replace oil and components such as plugs and sockets.

- Q: How much oil the three tons of forklifts are for a kilometer

- The 3-ton forklift is about 3 to 4.5 liters of oil. Forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. International standardization organization ISO/TC110 is called an industrial vehicle. Often used for the transportation of large items in storage, usually with a fuel engine or battery. The technical parameters of forklift are used to indicate the structure and performance of forklift vehicles. The main technical parameters are: rated lifting weight, load center distance, maximum lifting height, door frame, dip Angle, maximum speed, the minimum turning radius, minimum clearance from the ground and wheelbase, wheel track, etc.

- Q: What are the rules for the forklift

- The forklift management system In order to standardize the management of enterprises, to make the production safety work, the special system is formulated. First, safety management Safety education (weekly) for forklift drivers. 2, the operator must hold relevant certificates and strictly implement the safety operating rules, and the drivers are careful, to yearly check of forklift, qualified by the municipal labor bureau confirmed rear can continue to use a forklift driving and; Strictly according to the motor vehicle driving requirements in the factory: Do the inspection of forklift truck every day (according to the checking table) to keep the forklift in good condition.

- Q: What if the forklift oil is burned and the oil is burned

- Gas in the tubing, not oil.Have you had electricity for half a day? Electricity is not enough,

- Q: Diesel forklifts generally take a long time to replace the oil

- For the first time in the period suggested 50 hours to do the first oil change And with better oil level is above the CD, if you use the bad environment, see the purity of the oil, without a viscous dark or replaced. After the mill period, change every 200 hours. Basically 200 hours, the best method is to look at oil

- Q: Does the forklift have only one wheel? Front engine

- The two wheels are two sticks stuck can't turn a circle, and mat under the hard objects slippage of the wheels, the as long as let slip side is enough resistance can

- Q: What do you need to do to get a forklift license from the quality technology supervision bureau? Is there a practical test for the forklift truck?

- The driver of forklift has written test and practice exam, which is divided into two major categories, the pile test and the road test. There are different ways of testing in the area. Some areas are the actual driving forklifts, the actual operation of driving forklifts, the inspection of the rods, the line, the start, the fork, etc. This reflects the management of a region.

- Q: What do you mean by the center spacing of the load on an electric forklift?

- Load center distance In short, it means the center of gravity of the cargo. For example, the length of the fork is one meter, and the center of the load is half a meter away. In turn, the 1.8-meter-long cargo fork, the center of the payload is 0.9 meters away. It is dangerous to use a one-meter fork fork, which is 1.8 meters long, and the center of mass of the cargo is at 0.9 meters. It's likely to fall!

- Q: Learn the forklift truck, will you be tired in the future?

- Compared to talking about the forklift in the production line, but any job that lasts longer is tiring.

- Q: Where to test for a forklift?

- The general exam is to seek the quality board to register, but as you say, ask to provide the data to be more strict If you don't have to do it yourself, it's a lot easier to do it, but I can do it in detail

- Q: The depreciation period and the rate of depreciation of engineering machinery such as forklift truck

- The depreciation of engineering machinery is five years The invoicing price is depreciated according to the actual amount

Send your message to us

Forklifts - Heavy forklift - FD200B forklift

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords