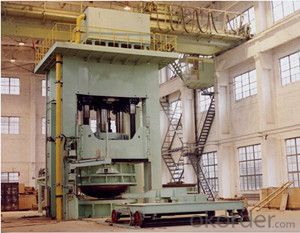

Forging Equipment Other Hydraulic Press Electrode Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI’s electrode presses are used for pressing formation of sponge and particle rare metals such as sponge titanium and sponge zirconium. Our pressed electrodes are used for producing titanium and its alloys, and zirconium and its alloys. They are widely used in fields such as aviation, spaceflight and nuclear power.

Our electrode presses include 50MN, 60MN and 80MN models. We also can design and manufacture corresponding electrode presses with other specifications per customers’ requirements.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: What brand of foreign brands punching machine, seeking answers

- It is driven by switched reluctance servomotor. The servo press has the characteristics of high efficiency, high reliability, maintenance-free, intelligent intelligent CNC, high precision products and has been exported abroad.

- Q: 16 punch stuck

- 16 tons of punch for the small tonnage mechanical rigid clutch punch, a drive, driven by the motor directly drive the crankshaft to drive the slider up and down movement.

- Q: Pneumatic punch a work, the inverter shows how the matter

- The inverter in the work to stop the general are reported overload alarm more, it is recommended to find the electrical engineer to adjust the corresponding parameters of the inverter

- Q: Punching machine punching force is generally how much

- I still know a little about punching the hole.

- Q: What is the purpose of the punch

- Can be made of blank, can make blanking, punching, forming, drawing, finishing, fine red, plastic, riveting and extrusion, etc., are widely used in various fields.

- Q: Does anyone know that Taiwan is doing punching company which is more famous?

- Hello, very honored to answer your questions.

- Q: Who is invented?

- In 1851, the United States Elias Howe applied for a similar zipper design patent zipper development history With the development of human social economy and science and technology, zipper from the initial metal materials to non-metallic materials, single species single

- Q: What is the maximum number of stamping machines in the world?

- 14,000 tons of hydraulic press up to 17.5m, about 5 stories high, the maximum forging weight of 600 tons of steel ingots.

- Q: Iron plate punching machine

- 60-100 tons can be, how do you use the `` `

- Q: What is the difference between the punching machine and the hydraulic press?

- The working principle of the punching machine is generally crank press, driven by the motor flywheel, and through the clutch, transmission gear drive crank connecting rod mechanism to move the slider up and down, driving the drawing die on the steel plate. The so-called double action refers to the press

Send your message to us

Forging Equipment Other Hydraulic Press Electrode Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches