Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

1. Specification of Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

Diameter: 20mm-150mm(0.75''-6'')

Hardness: 50HRC-65HRC as your request

Breakage Rate<0.5%

Impact Toughness>12J/cm2

Endurance Test>10000times

2. Chemical Composition of Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

Based on material,the forged steel balls are defined into 7 brands. And The chemical composition is shown in the following:

Brand | Material | C | Mn | Si | Cr | S | P |

CMAX-1 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-2 | 60MN | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.030 | ≤0.030 |

CMAX-3 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.030 | ≤0.030 |

CMAX-4 | 75Mn | 0.72-0.92 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.030 | ≤0.030 |

CMAX-5 | 75MnCr(B2) | 0.70-0.85 | 0.7-1.20 | 0.17-0.37 | 0.4-0.8 | ≤0.030 | ≤0.030 |

CMAX-6 | 75SiMn | 0.70-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.030 | ≤0.030 |

CMAX-7 | Wear-resistant Alloy | | | | | | |

Based on material, the casting steel balls are defined into 6 brands. And The chemical composition is shown in the following:

Name | Model | Material | C | Si | Mn | Cr | S | P |

CMAX-8 | High Chrome | Cr-22-32% | 2.0-2.8 | ≤1.0 | 0.5-2.0 | 22-32 | ≤0.01 | ≤0.01 |

CMAX-9 | Cr-17-22% | 2.0-2.8 | ≤1.0 | 0.5-2.0 | 17-22 | ≤0.01 | ≤0.01 | |

CMAX-10 | Cr-14-17% | 2.2-3.0 | ≤1.0 | 0.5-2.0 | 15-17 | ≤0.01 | ≤0.01 | |

CMAX-11 | Cr-10-14% | 2.2-3.2 | ≤1.0 | 0.5-2.5 | 11-14 | ≤0.01 | ≤0.01 | |

CMAX-12 | Medium Chrome | Cr-5-10% | 2.1-3.2 | ≤1.2 | 0.5-1.5 | 5-10 | ≤0.01 | ≤0.01 |

CMAX-13 | Low Chrome | Cr-1-5% | 2.2-3.5 | ≤1.2 | 0.5-1.5 | 1-5 | ≤0.02 | ≤0.02 |

3. Production Process of Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

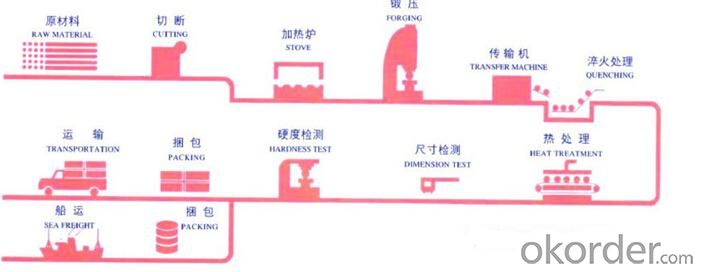

Production Process for Forged Steel Grinding Ball

(1)Raw material.(2)Cutting.(3)Heating.(4)Forging.(5)Quenching.(6)Tempering.(7)Testing.(8)Qualified Products.(9)Packing

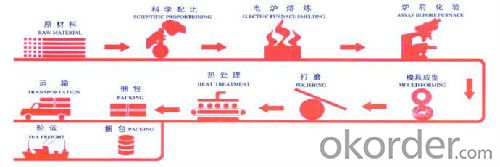

Production Process for Casting Grinding Ball

(1)Raw material.(2)Scientific Proportioning.(3)Electric Furnace Smelting.(4)Assay Before Furnace.(5)Mould Forming.(6)Polishing.(7)Heat Treatment.(8)Qualified Products.(9)Packing

4. Packing Ways of Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- uch as: automobile transmission shaft adopts mechanical rolling machine with good performance, gray cast iron can play seismic effect effectively, with good thermal conductivity of radiator graphite in gray cast iron, the aircraft engine turbine blade by casting directional solidification casting and Dan Jingzhu.Do everything we can to make the best use of it, the advantages and disadvantages of rolling and casting, and you'll find it yourself, Baidu, depending on how you use it

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron.

- Q: Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Forged Steel Grinding Ball & Casting Grinding Ball with Very Good Quality and Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords