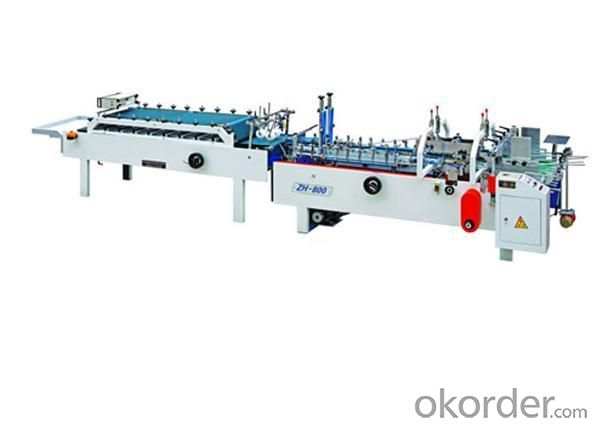

Folder Gluer ZH800/800C/880/1000

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1 Sets per Week set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Folder Gluer ZH800/800C/880/1000

1. wide applying area

2.easy to operate

3.reasonable price and good after-sales service

4.CE certificate

Model PRYZH-800 is the companys main push ordinary type folder gluer, its stability, versatility and flexibility are uses praise. Small to large box can paste with this box gluer. For small boxes, it can make 40,000 to 50,000 pcs per hour It is an Ideal gluing equipment for printing industry.

Features of Folder Gluer ZH800/800C/880/1000

1. | Line speed:0220m/min continuous adjustment. |

2. | Usage paper:210600g/ Paperboard |

3. | The box forming: Either sides folds, the both sides prefold and either side glue. |

4. | Paper feeding: Automatic feeding |

5. | Binder: Dissolve the type. |

6. | Electric: Single-phase AC220V 2.2KW |

7. | Weight:1800kg |

8. | Dimension:5800×900×1300(mm) |

9. | The counting range:0999999(full-automatic) |

Main Technical datas of Folder Gluer ZH800/800C/880/1000

Model | (A Max) | (A Min) | (B Max) | (B Min) | (C Max) | (C Min) | Use the amount of electricity | Governor extent | Weight | Contour dimension |

PRYZH-800 | 560mm | 105mm | 550mm | 50mm | 270mm | 50mm | 220v 2.2kw | 0220m/min | 1.5T | 5800×900×1300mm |

PRYZH-800C | 560mm | 65mm | 550mm | 50mm | 270mm | 30mm | 220v 2.2kw | 0220m/min | 1.5T | 5800×900×1300mm |

PRYZH-800G | 660mm | 105mm | 550mm | 80mm | 330mm | 50mm | 220v 2.2kw | 0220m/min | 2.0T | 5800×1050×1300mm |

PRYZH-1000 | 760mm | 130mm | 600mm | 80mm | 380mm | 60mm | 220v 2.2kw | 0220m/min | 2.3T | 5800×1200×1300mm |

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Southeast Asia; Mid East; South Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Folder Gluer ZH800/800C/880/1000

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1 Sets per Week set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords