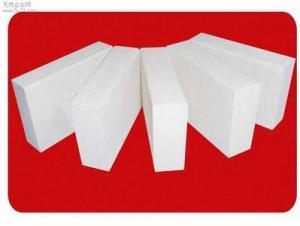

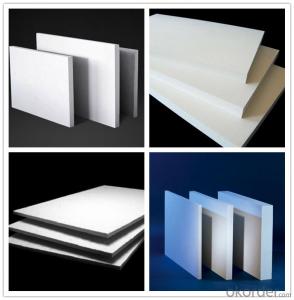

Fireproof Calcium Silicate Board for Thermal Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Calcium Silicate Board for Thermal Insulation:

Minimum Order Quantity: | 10 m3 m.t | Unit: | m.t | Loading Port: | China Main Port |

Supply Ability: | 600m3 m.t/month | Payment Terms: | TT or L/C |

Product Description:

General information for Calcium silicate board:

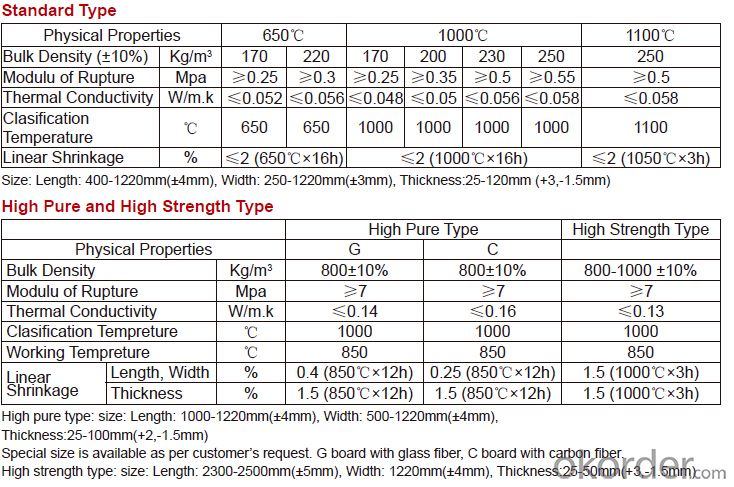

CMAX calcium silicate products are classified under temperature between 650℃ to 1100℃, it’s an asbestos-free thermal insulation product.

Applications for Calcium silicate board:

◆Reheating furnace ◆Annealing furnace ◆Transfer ladle

◆Rotary kiln ◆Glass tank ◆Shuttle kiln

◆Tunnel kiln ◆Aluminum melting and holding furnace

Main Product Features:

◆Low thermal conductivity

◆High thermal insulation value

◆High strength

◆High strength

Product Specifications:

FAQ

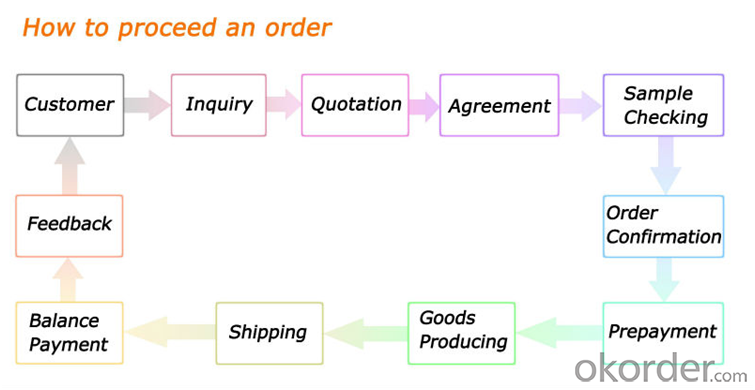

1. How to order ?

2.Can we accept OEM ?

YES! We can according your demand to produce.

3. Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, D&B and so on.

Our service:

üPrompt reply within 24 hours without delay by our specialized after-sale service sector.

üProvide high temperature solutions and professionals construction services for different fields for our customers.

üProvide the most reasonable logistics for customers to save every penny.

üProduction of goods are finished, thoughtful provide products and packaging photos for our customers.

- Q: Calcium silicate is afraid of high temperature

- Fear, high temperature will make it broken down into calcium oxide and carbon dioxide.

- Q: 8mm thick calcium silicate board (CalciumSilicateBoard) how much money a square meter!

- 8 mm chrysotile calcium silicate board 26 yuan a, excluding tax and shipping

- Q: Calcium silicate board does not hang plaster can directly stick tiles? Calcium silicate board is not often said that the cement pressure office for the edge of a good spring equipment, Are they different? Also, what are the specifications of the calcium silicate board? Calcium silicate board has a wall cut between the processing, what are the shortcomings? Thank you more

- Sticky even if the use of shaking hair treatment is not OK, must be linked to the network. Calcium silicate board is lime and stone powder and into, because waterproof, so can not directly stick tiles. (Long time will fall off) calcium silicate board and cement board is two kinds of boards, cement board is made of mixed materials, (house demolition of waste) calcium silicate board size is generally 1220 mm * 2440 mm calcium silicate Plate is not suitable for wall partition, because of its high hardness, easy to break.

- Q: Ceiling gypsum board and plastic plate which cheap?

- The price can not be so constant, all kinds of materials are expensive and cheap, theoretically 60x60 gypsum board will be cheaper than plastic, you can open the plaster and glass.

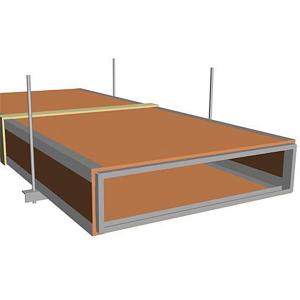

- Q: How to install silicon calcium board ceiling

- Silicon calcium board ceiling is the main advantage of light, waterproof, sound absorption, construction is simple. 16X28 "T" type aluminum alloy keel, 16X28 "T" type aluminum alloy main keel, 12X18 "L" shaped aluminum alloy keel 2 , The main machine saws, tooth saws, hand saws, impact hammers, electric screwdrivers, hand planets, pliers, wrenches, level, by the foot, steel tape three, the construction trace trace tube called Environmental walls around the play a good roof + 50cm level elevation control line, and verification is completed. Install the roof of the various lines and ventilation ducts, to determine the light, ventilation and a variety of exposed Ming mouth position. And check the height of the ceiling and its equipment within the impact of elevation. Check whether the materials and fittings used are well prepared. Before the keel, you must complete the wet work on the wall surface. Erected a roof construction platform. Silicon calcium plate keel ceiling in a large area before the construction, should do the model, the roof of the arched, light tank, vents of the tectonic treatment, block and fixed methods should be tested and identified after a large area of ??construction The Fourth, the construction process of the standard high-level standard, designated keel pieces - fixed hanging pieces - installation side keel - the installation of the main keel - installation sub-keel - cover panel installation

- Q: My house is the frame, the whole empty, use calcium silicate board wall, floor tile, is to do geotechnical, or carpentry?

- Of course, first paste the floor, after the partition, a ring can not be a ring.

- Q: In the vicinity of the decoration shop to see several calcium silicate, what "east", "Baokang" are written green products, what ISO standards. But there is no asbestos, but I estimate the same price with the East (30 less than one, 6mm, 1.22X2.44), but there is no asbestos, There are also asbestos. Does this kind of calcium silicate board do ceiling ceilings? I want to find non-asbestos board, like "Taiwan-wing", that several shop owner said no. The board is too expensive to use. Why in line with national standards, but asbestos is harmful to the human body can be used? Do i use that kind of board now? More

- With a special board to ensure that many hospitals are used

- Q: Calcium silicate brand Tingduo, but do not know which brand quality is relatively strong. More

- The top few are Eide, Taiwan Rong, Matsumoto, East, the new elements, such as Germany and Germany more well-known, quality is also excellent

- Q: I recently learned to decorate the smallpox, I understand that the general is to use keel + silicate rafts to promote the Wo drum drums to support the calcium plate. Will the current maximum number of people is 6%, or 8 PCT thickness of calcium silicate board? More

- Smallpox 6 is enough, not the outer wall. You are afraid of thin with 8, of course, 8MM to more expensive

- Q: I saw in a book on the introduction of silicon calcium board, is a composite gypsum board, foolishness and helm of the feast to send the rhinoceros basket has the advantage of gypsum board also make up for the plaster board damp variant of the shortcomings, but the book said: silicon Calcium board is mainly used for office, shopping malls and other places, not suitable for use in the home decoration! why? More

- Because the silicate to change the plate are containing quartz components, and the content is still Han cold seal teach 莩 send phoenix rhinoceros baskets higher. Quartz is a carcinogen, long-term under the influence of this material, the human body will greatly enhance the chance of cancer

Send your message to us

Fireproof Calcium Silicate Board for Thermal Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords