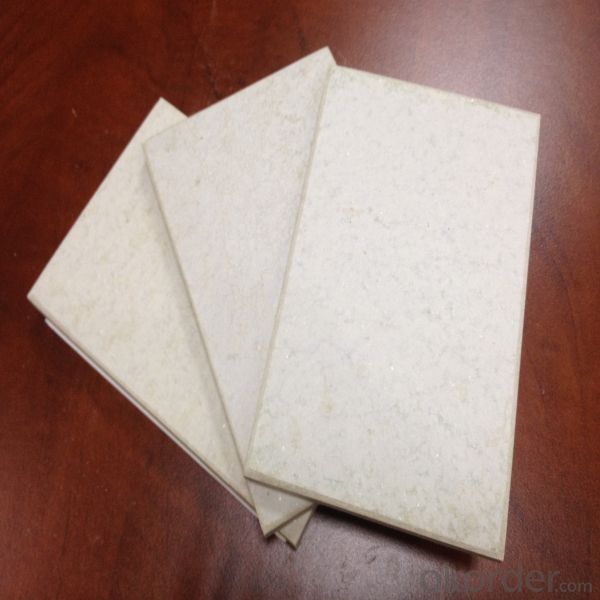

Ceiling calcium silicate board trim living room partition,for hotel office home school hospital,Europ standard, BS certification

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 88000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Component

fiber cement board is manufactured from Portland cements; Lime; Quartz; Cellulose fiber; additives and water. It does not contain asbestos, brucite , meerschaum, glass fiber and formaldehyde.

Product advantage/features:

l Healthy and Environmental

All the product is 100% no asbestos and other harmful composition.

All the product is recyclable,degradable.

l Noise-reduction

This board have the good function of sound dampening.

l Termite/Vermin Resistant.Rot Resistant

Most composition are inorganic material, proceed in the high temperature and high pressure.

l Non-combustibility

Reach the GB 8684 class A1, BS 476 part 4.

l Light and strong

High density, strong, but light weight. Reduce building’s weight, earthquake-proof.

l Long lifespan

Most composition are inorganic material, proceed in the high temperature and high pressure.

Stable performance, the lifespan mostly keep same to the building.

l Convenient to use

Outstanding product, very smooth surface without defect, directly use without processing again.

l Easy to process

It’s available used for the drywall system, reduce the time and labor. Traditional sticking is also ok.

Besides, this board can be lacquering, glue, bonding, punching, cutting, screwing, contour cutting, routing.

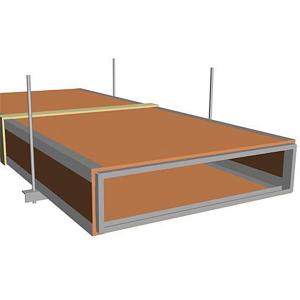

l Easy to install

This board use with the common metal accessories. Easy to buy and install.

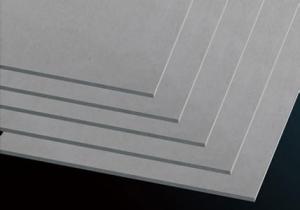

Specification:

Product size | |

Length | 2440mm |

Width | 1220mm |

Thickness | 4/6/8/9/10/12/15mm |

REMARK: We can also supply other specification as the client’s specially requirement | |

Physical properties:

The following data are the average tested figures during manufacturing

Product specification | ||

Density | 1.2~1.45 g/cm3 | |

Water absorption | ≤39% | |

Water contain | ≥10% | |

Non-combustibility | A1 grade Non-combustibility | |

Bending strength | Cross | ≥12 Mpa |

Parallel | ≥10 Mpa | |

REMARK: Please contact our technical department if you need more technical index. | ||

Loading

Base board loading quantity: | |

1X20GP | 1X40HC |

4mm: 1144PCS | 4mm: 1440PCS |

6mm: 856 PCS | 6mm: 1080 PCS |

8mm: 660 PCS | 8mm: 840 PCS |

9mm: 560 PCS | 9mm: 720 PCS |

10mm: 512 PCS | 10mm: 648 PCS |

12mm: 428PCS | 12mm: 540 PCS |

15mm: 342PCS | 15mm: 432PCS |

Factory info

Our factory owns 260,000 square meters, 500 meters long production line, 4 patents. Sales office is just 45 minutes driving from Guangzhou midtown. Should any chance, welcome to visit us. Attached are sample photo and factory photos.

- Q: Calcium silicate board can be recycled

- can!

- Q: Export of calcium silicate board or gypsum board, which one shipping cheap?

- The problem is high. How is the freight? First answer the following questions 1. Air / sea / land / courier, etc. which you choose 2. From where to where 3. The volume of goods Fu tiger brother Xi Xi Ding Ding Ding busy gross weight 4. Start time to think These three questions and then look for freight forwarding companies, different ways of transport billing in different ways, such as shipping: General you can charter / bulk cargo container is also very thin 40 Pu 40 ultra high 20 small cabinet special cabinet (frozen What kind of) air there are two kinds of billing: give you 2 price XX yuan / kg XX yuan / party according to your weight and volume of goods are calculated to calculate which is your preferred. Different airlines have different Of the starting standards, and some less than one party by a formula, and some side by side by two formulas, so the three questions to find out, looking for a freight forwarding. So that you can have a more accurate freight

- Q: Silicon calcium board wall how to paste tiles

- 1, in the wall hanging steel wire mesh 2. Plastering will find a vertical wall to find the vertical 3. Do waterproof layer 4, on the wall side of the hair 5. Tiling

- Q: Fiber cement pressure plate and calcium silicate board What is the difference, what is the use

- Differences: 1, their raw materials are different. Calcium silicate board is the use of siliceous, calcium material and a certain proportion of fiber materials as the main material, by the pulp, molding, autoclaved curing from. Fiber cement is based on fiber and cement as the main raw material for the production of cement cement plate. 2, fiber cement pressure plate bending strength is V level, calcium carbonate board strength is IV level. Fiber cement pressure plate than calcium silicate board strength. Uses: Calcium silicate board and fiber cement board are common architectural decoration materials on the market, used in the construction of ceiling ceilings and partitions, home decoration, furniture liner, billboard liner, ship cabin, Board, network floor and tunnel and other indoor works of the wall; commercial buildings of commercial buildings, entertainment and bathing places, shopping malls, hotels; industrial buildings of the factories, warehouses; residential buildings of the new residential, renovation renovation; public places hospitals, theaters , Station, subway and so on. The main use is the wall, ceiling, floor, furniture, road insulation, sound absorption barrier, ship compartment and duct and other industrial panels and suction walls, sound absorption ceiling, pouring walls, composite wall panels and other fields.

- Q: Living room to do silicon calcium board ceiling, whether need to put putty, brush latex paint?

- need. Gypsum board ceiling not only need to put outside the putty. The first step: first have to fill the first seam, the gypsum board interface first fill the seam to scratch the gypsum sticky powder or patchwork; the second step: and then paste kraft paper or cloth. The third step and then putty putty, if the wipes of environmental putty do not need point anti-rust paint, and will not rust. But if the scraping bucket glue putty must be a point anti-rust paint, and if no point will be rusty. The fourth step: usually gypsum board after filling the general two lowest putty. Not recommended to scratch three times. Too thick but easy to fall out.

- Q: Silicon calcium board ceiling keel is what material

- Are generally metal keel! There are 38 main keel, T-shaped main keel, and vice keel.

- Q: Silicon calcium board ceiling specifications which? Silicon calcium board ceiling brand which?

- Recommend you with the top ten brands: 1, allies ceiling 2, Aopu integrated ceiling 3, Rong Sheng integrated ceiling 4, character integrated ceiling 5, Meiling integrated ceiling 6, France lion dragon integrated ceiling 7, Chu Chu full ceiling 8, Austrian integrated ceiling 9, Vantage integrated ceiling 10, modern integrated ceiling silicon calcium board ceiling Specifications: 1: ceiling on the calcium silicate board specifications on the ceiling are 1200 * 600,300 * 300,300 * 600,595 * 595, the thickness is mainly 15mm. Other special specifications are mainly to the manufacturers scheduled. 2: partition board in the wall board applications, silicon calcium board specifications are: 603 * 603,2440 * 1220,2400 * 1200, the thickness is mainly 15mm.

- Q: Calcium silicate board how much money a square ah

- Calcium silicate board thickness is different, different density, length and width specifications are different, calcium silicate board generally have 10-50 per month, depending on the brand and quality of silicon calcium plate difference, but it is recommended not only look at the price Ignoring the ceiling of the quality works of the ceiling ceiling and partition, home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall.

- Q: What waterproof material moisture in the decoration?

- Gypsum board basically divided into 3 kinds: ordinary paper gypsum board, moisture gypsum board, fire gypsum board; moisture price of the burden of heavy delivery 郛 Hao shop Tong Chung profile; calcium silicate board is not environmentally friendly, there are many shortcomings, I will Inconvenient to say.

- Q: Ceiling silicon calcium board and mineral wool board which is better

- Silicon calcium board is better than gypsum board

Send your message to us

Ceiling calcium silicate board trim living room partition,for hotel office home school hospital,Europ standard, BS certification

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 88000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords