Fireclay Brick with High Alumina Content Alumina for Laying Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

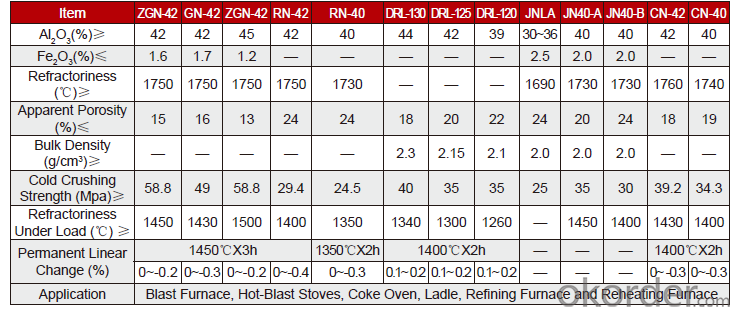

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What kind of refractory brick is suitable for 1400 degrees shuttle kiln?

- Corundum mullite

- Q: What is the meaning of special shaped refractory brick material n-2b?

- In fact, there are many kinds of refractory bricks, titanium, high alumina refractory brick, after drying. The mineral composition of the clay brick is mainly kaolinite (Al2O3·2SiO2·2H2O) and 6% ~ 7% impurities (K, etc.). Clay refractory bricks are iron oxide sintered by 50% soft clay and 50% hard clay clinker ingredients according to a certain granularity requirements under the high temperature of 1300 ~ 1400 degrees), perlite

- Q: Are refractory bricks, burner block and thermal insulation brick the same? Are they the same thing?

- the proportion of raw materials of refractory bricks and thermal insulation bricks. chain of various types of products

- Q: How to prevent the refractory bricks from burning to crack?

- This may result from formula. Prevent the refractory bricks from being overweight. Firstly, sintering agent should not exceed the standard, when sintering, bricks must be well piled to piled bricks, and the bricks must be dry.

- Q: How to adjust the temperature in the 160 meter tunnel kiln?

- Tunnel kiln can be attemperated by burning products, this will not affect the firing of different products, and can burn back processing products.

- Q: How many squares of a ton refractory bricks?

- About 2 tons , general one square clay brick is about 2 tons, from 2, one square corundum brick or magnesia bricks can reach 3 tons, it should say one square is how many tons. if it is high aluminum, then see the content of aluminum. It mainly sees what refractory bricks, because the volume and density of refractory bricks are relatively large.2 tons to 2

- Q: What can be applied to the burned refractory brick to resist heat shock?

- Acidic refractory material use monox as the main component, among which cilica brick and clay brick are commonly used. Silica brick is silicious product containing monox more than 93%, whose raw materials include silica, waste silica brick scrap and etc. The acid resistance of slag erosion ability is good, and the softening temperature under a fixed load is high. The volume won't shrink after repeated burning, but even a slight expand; but it is vulnerable to the erosion of basic slag, and has low thermal shock resistance. The silica brick is mainly used for coke oven, glass melting furnace, acid hearth furnace and other thermal equipments. Clay brick uses refractory clay as the main raw material, containing 30% to 46% of aluminuum oxide, belong to weakly acidic refractories. It has good heat shock resistance and corrosion stability to acid slag, and it's widely used. Neutral refractory materials use aluminum oxides, chromium hemitrioxides or carbons as the main components. Corundum products containing more than 95% of alumina is a kind of high quality refractory material with wide application.

- Q: What material does tile tunnel kiln use to replace the refractory brick to have better insulation effect and save the maintenance and prolong the service life?

- You can use ceramic fiber module

- Q: What is the clay used to make the refractory brick?

- Lining brick of teeming ladle; refractory clay used in building materials industry to produce high alumina bricks for cement kilns and glass furnaces, as well as anti sliding, high alumina lining bricks and high alumina refractory clay. The hard clay in refractory clay is used for making blast furnace refractory material, which is used in agriculture as a fertilizer promoting agent and, and electron. High alumina clay is also used in the oil well, generally does not disperse in water. In metallurgy, accounts for 2/3 of abrasive products, and so on. Hard clay and semi hard clay can be used to manufacture daily-use ceramics. High alumina clay after calcination, which has high temperature resistance! Refractory clay refers to the degree of fire resistance is greater than 1580, the hardness and proportion is relatively big, the refractoriness is good. They except has relatively high refractoriness. Such as aluminum sulfate, its dosage accounts about 70% of all the refractory materials;

- Q: Why are clay bricks used when buildings are below zero? Frost heaving, water absorption, or something?

- The following buildings plus or minus zero use of clay bricks is used because the clay brick has good water absorption, can make the capillary water in the soil up to the clay brick, clay brick is absorbed, so as to prevent the capillary water rising effect

Send your message to us

Fireclay Brick with High Alumina Content Alumina for Laying Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords