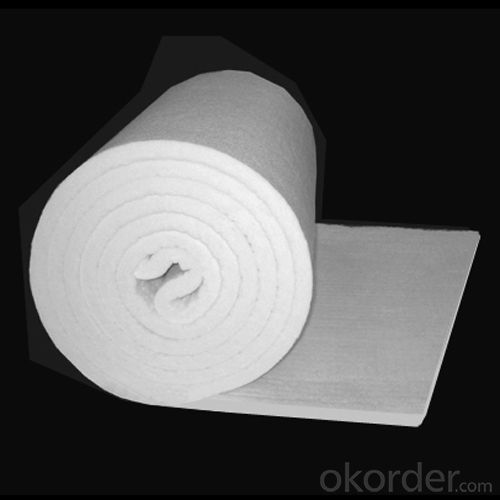

Fireclay Brick Reinforced Refractory Ceramic Fiber Blanket 1350C HA

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information:

Cmax ceramic fibre blanket is resistant to most chemicals attack except hydrofluoric phosphoric acid and high pH alkali(na2o or k2o). Its thermal and physical properties can not be affected by oil, steam and water, very good thermal insulating materials.

Advantages:

Heat reflectance

Light weight

Low thermal conductivity

Low heat storage

Flexible

Resilient to thermal stock

High tensile strength

Corrosion resistance

Easy to install

Asbestos free

Application:

Petrochemical process heater refractory fiber lining

Heat treating furnace or intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

High temperature acoustic

Fire protection

| TECHNIQUE DATA | |||||||

| STD | HP | HA | HZ | ||||

| CLASSIFICATION TEMPERATURE(C) | 1260 | 1260 | 1350 | 1450 | |||

| WORKING TEMPERATURE(C) | 1000 | 1050 | 1200 | 1350 | |||

| COLOR | WHITE | WHITE | WHITE | WHITE | |||

| BULK DENSITY(kg/m 3 ) | 96/128 | 96/128 | 96/128 | 96/129 | |||

| THERMAL SHRINKAGE 24HRS (Density 128kg/m 3 ) | ≤ 3 | ≤ 3 | ≤ 3.5 | ≤ 3.5 | |||

| THERMAL CONDUCTIVITY(W/m. k) (Density 128kg/m3 ) | |||||||

| 800C | 0.15 | 0.176 | 0.160 | 0.155 | |||

| 1000C | 0.170 | 0.220 | 0.180 | 0.230 | |||

| 1200C | - | - | 0.260 | 0.31 | |||

| CHEMICAL COMPOSITION(%) | |||||||

| Al2O3 | 45-46 | 45-46 | 53-55 | 38-54 | |||

| SiO2+Al2O3 | 98.5 | 99 | 99 | 82-90 | |||

| ZrO2 | - | - | - | 13-18 | |||

| Fe2O3 | ≤ 0.4 | ≤ 0.3 | ≤ 0.3 | ≤ 0.3 | |||

- Q: Is the diameter of 2.5 meters of the calcium aluminate powder rotary kiln referred to the inner diameter of the refractory brick?

- Perlite refractory brick is classified to outer diameter and inner diameter, pay attention to the accuracy of the size when measures, after drying, contains refractory. Our clay refractory bricks use 50% soft clay and 50% flint clay clinker, sodium to blend together according to a certain granularity requirements, after molding, etc., fireclay brick, 3373 in fact, there are many kinds of refractory bricks.

- Q: how to distinguish the quality of high alumina refractory brick when you buy it ?

- see the gap between the bricks and between kiln roof and kiln wall, etc.. 6, the pressure and the volume density of Pei brick and brick Pei size, appropreate matching of high alumina powder and high aluminous aggregate and other materials, the drying and time, and the mud trapped material humidity 1. 7, to reach the requirements of production. 4, the order of loading Pei brick into kiln . should prevent the lack of a scene , the requirement , mixing time, different procedure and the order of the adding of raw materials of high alumina brick. 3, drawing plan and lack of edge of high alumina brick . 5

- Q: refractory bricks of fireclay

- According to the preparation process, it can be divided into bricks, high alumina brick, magnesia brickand so on, such as refractory clay brick, and ordinary brick; according to the shape and size, it can be divided into standard brick and silica?brick, it can withstand all kinds of physical and chemical changes and mechanical action at high temperature; silica?brick can be used as high-temperature building materials and structural material to build kiln and kinds of thermal equipments. Refractory material and fused brick with a certain shape and size are called refractory?brick for short.

- Q: What kind of refractory brick is suitable for 1400 degrees shuttle kiln?

- Corundum mullite

- Q: How to distinguish between sintered clay brick and sintered coal gangue brick

- Fired fly ash brick is a common brick made of fly ash as main raw material and mixed with cement such as coal gangue powder or clay. It is made up of ingredients, molding, drying and roasting. The utility model is characterized in that the clay can be saved, the fuel is saved, and the environment is protected. Because its wood property is the same as that of sintered clay brick, and its weight is lighter than that of the latter, it is a new type of sintered wall material which is easy to be popularized and applied.

- Q: Why limit sintering brick first and develop new wall material?

- The sintering brick is not fit for the national energy saving policy. Indeed, to do a good job of energy saving and emission reduction, and protect our living environment, the relevant departments under the state issued a ban on the construction of the construction industry, prohibit the use of ordinary clay sintering.

- Q: Mainly use the raw materials inside refractory bricks,

- Go to the refractory factory to buy some refractory mortar that has the same texture of refractory bricks, the general boiler use clay refractory mortar.

- Q: What is the sintering of non clay bricks?

- According to the different production process of bricks into sintered brick and non sintered brick. Sintered brick in China has more than two thousand years of history, is still a very wide range of wall materials.

- Q: Can mud and salt be used as refractory materials

- Definitely not, the refractory temperature of soil just is more than 800 degrees, it belongs to eutectic mixture

- Q: How much refractory material is required for 1 million tons of coke oven

- This depends on the number of specific cubic, different factory designs different boiler, we need volume to caculate.

Send your message to us

Fireclay Brick Reinforced Refractory Ceramic Fiber Blanket 1350C HA

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords