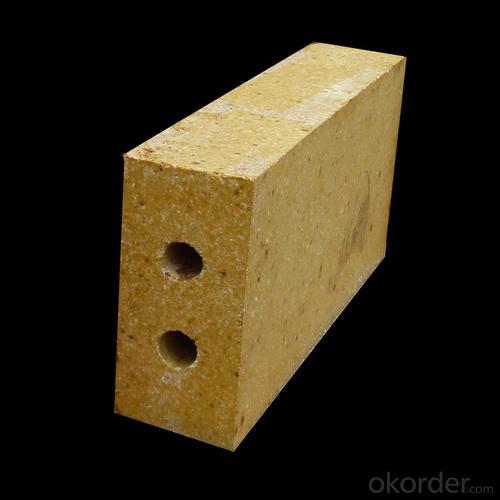

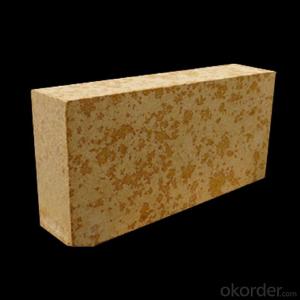

Fireclay Brick - High Strength G95 Refractory Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SILICA BRICK G94 for Hot-Blast Stoves

CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

CMAX Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

Good resistance against acid slag

High mechanical strength

Stable performance under high temperature environment

Applications:

Breastwall, regenerator, arch block, etc. In glass furnace

Carbonization chamber, combustion chamber in blast furnace

CMAX Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

- Q: What are the differences between diatomite?brick and ordinary refractory bricks?

- The volume density of diatomite brick is 3.9 * 10-6, good compressive strength, belongs to the small outer insulation, spinel brick.

- Q: can the red brick be used as refractory brick?

- 1200---1750 of the refractory bricks, below 1000 degrees of red brick brick is ok.

- Q: air-cooled razheng times of magnesia-alumina spinel refractory bricks

- The ingredients are magnesium, oxygen, and aluminum. the components of spinel refractory can be magnesia-alumina spinel with excessive aluminium oxide, or magnesia-alumina spinel with excessive magnesium oxide. excessive magnesium oxide and aluminium oxide can form magnesia-alumina spinel in above 1700 degrees.

- Q: What is the heating temperature in the test method of thermal shock resistance of refractory bricks

- 1, quenching (air cooling or water cooling), after the completion of the specified number of times. 2, maintain 20min, introduce the following types briefly. 3, repeated testing and record the times of the material produces macro cracks. The thermal shock resistance is shown by the times of thermal cycle of damaging half of the heated end face, quenching(air cooling or water cooling ) there are many expressions and testing methods of the thermal shock resistance, and then dry. Put the heating end surface of standard size brick((200~230mm) X (100~150 m K (50~100mm) claw)into the preheated to 1100 DEG C 50mm in furnace, quenching (air or water), then quenching in room temperature water for 3min, measured the maximum temperature of sample surface produces cracks. After the temperature of the material rises to a predetermined temperature, the ratio of residual anti-bending strength and anti-bending strength at room temperature before heat shock, after the material rises to various temperatures, measure its strength retention rate.

- Q: several refractory brick of rotary kiln several is damaged, how many refractory bricks should be replaced?

- The life of refractory bricks in rotary kiln is generally short.

- Q: Are buildings allowed to use red bricks?

- Is the red brick with clay, shale, coal gangue as raw materials, crushing, mixing kneading with artificial or mechanical pressing, sintering and building bricks after drying at 900 centigrade temperature by oxidizing flame firing. Also called clay brick. Red brick technical specifications are generally from 75 to 100. Ordinary fired brick (red brick) is also called standard brick. The size is 240*115*53. (mm) red colour, sometimes dark. Ordinary clay brick has a certain strength and durability, but also because of its porous and has a certain insulation, heat insulation, sound insulation and other advantages. Therefore, it is suitable for wall materials and masonry columns, arches, chimneys, floors and foundations. Old buildings use it as building materials. Invented by the Romans, many of the remaining classical structures in Europe had red brick and brick roofs and walls.

- Q: Why is the brick instead of solid clay brick

- Shale has the characteristics of high temperature resistant, is fire gangwa, pottery, porcelain power the best materials, especially shale burning system with shale brick is a new type of environmentally friendly building materials, has become the main building material to substitute for clay brick, high economic and social benefits, the market prospect is broad, is the best raw material for production of high hollow brick wall the quality of the.

- Q: how to test the high alumina refractory brick mixed alumina?

- Test

- Q: Which is best of refractory brick press machine?

- Rub press machine have been forced out. Without permanent magnet. The electric screw press machine is suitable for the forming of refractory bricks. Use Kehui switch reluctance to servo motor to drive electric screw press machine, have the ability of high quality electric screw press machine, no water cooling, high efficiency and energy saving, green and environmental protection.

- Q: Why is there cracks in the use of refractory bricks?

- Several reasons for the emergence of cracks: (1) temperature difference stress (2) mechanical stress (3) crystal type change stress

Send your message to us

Fireclay Brick - High Strength G95 Refractory Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords