Plywood MDF Film Faced Plywood with Top Quality 15mm & 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

| Product Name | Film Faced Plywood | ||||||||

| Size | 1220x2440mm(4'x8'), 1250x2500mm, 915x1830(3'x6') or as per your requirement | ||||||||

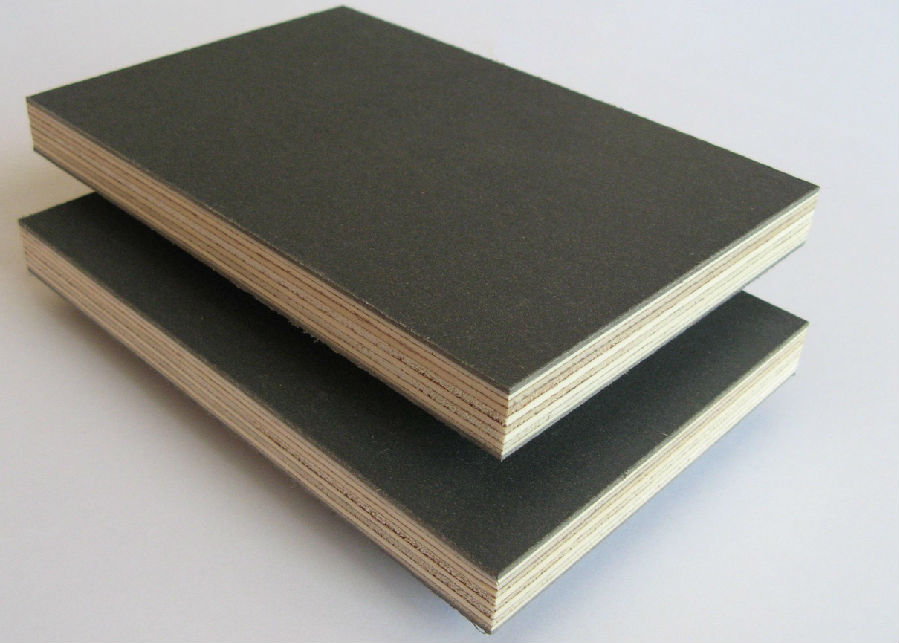

| Thickness | 8-24mm | ||||||||

| Thickness Tolerance | +/-1mm-+/-0.5mm | ||||||||

| Number of Plies | From 5 to 15 depending on thickness | ||||||||

| Face/Back | Black Film, Brown Film, Red Film (Film can be printed with requested logo) | ||||||||

| Finish | Glossy, Matt, Anti-slip | ||||||||

| Core | Poplar, Hardwood, Birch, Combined | ||||||||

| Glue | WBP, Melamine, MR | ||||||||

| Loading Quantity | 50cbm - 58cbm per 40'hq, 45cbm per 40'ft, 22.5cbm per 20'ft | ||||||||

| MOQ | 1X20'ft Container | ||||||||

| Lead Time | 15 days after receiving your prepayment or L/C | ||||||||

| Productivity | 8000cbm per month | ||||||||

| Packing | Inner with waterproof plastic bag, outside with plywood or carton, then fastened with 3'x6' sheet iron and packed with pallets | ||||||||

| Payment terms | TT or L/C at sight | ||||||||

| Production Advantages: | |||||||||

| 1Transference to concrete is set up very easily, so good for construction work. | |||||||||

| 2)Waterproof, Wear-resistant, anti-cracking. | |||||||||

| 3 After installation of concrete, the surface looks like a mirror. (The cement does not stick.) | |||||||||

| 4 It can be used to make camber and it also can be cut into small pieces according the special requirements. | |||||||||

| 5. Environmentally friendly. | |||||||||

| 6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time | |||||||||

Features:

1. In boiling water, it can keep glue-sticking and non-deformed for 60 hours at least.

2. Physical mood is better than iron moulds and can satisfy the requirements of

constructing mould ,while the iron ones are easy to be deformed and can hardly

recover its smoothness even after repairing .

3. If used abide by the illustrations strictly. It can be reused more than 50 times.

thus reducing the cost greatly and avoiding the disadvantages from

rusty and erosive of iron mould.

4. Solves the problems of leaking and rough surface during constructing process

5. Particularly suitable for watering concrete project because it can make

the concrete surface smooth and flat

6. Realizing a higher economic profits

FAQ:

1.Can I be your agent?

Yes, welcome to deep cooperation. We have big promotion in the market now. For the details please contact with our overseas manager.

2.Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3.Is the sample available?

Yes, samples are available for you to test the quality.

4.Are the products tested before shipping?

Yes, all was qualified before shipping. We test every batch every day.

5.What's your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

6.What's benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

Your can get good reputation from your market and obtain more orders.

- Q: Now what is the market for plywood development?

- the cumulative sales revenue was RMB 72,163,513,000, an increase of 39.25% over the same period in 2005; total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Quality grade for the premium, one, two, three a total of four, the indicator is similar to the MDF, but the intensity is much higher than the MDF

- Q: Selection of plywood in plywood production

- Natural wood veneer is made of precious natural wood, veneer or cut by the processing of veneer veneer

- Q: Plywood can improve timber utilization and is a major way to save wood.

- Pure solid wood furniture is that all the furniture materials are solid wood, including the desktop, wardrobe doors,

- Q: Multilayer board and plywood difference

- multi-layer board is one of the commonly used materials processing enterprises, is a wood-based panel

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is one of the most commonly used materials for interior decoration

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

Send your message to us

Plywood MDF Film Faced Plywood with Top Quality 15mm & 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords