15/32 Film Faced Plywood - High Quality Top Sale

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

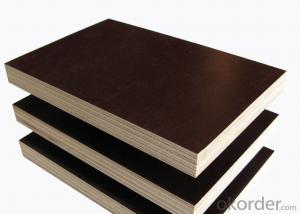

Specifications

1.size:1220*2440*1.7-35mm

2.surface:veneer,PVC,PU,UV,Melamine paper

3.material:poplar hardwood combi

4.usage:furniture,packing,construction

Good quality Commercial Plywood

Brief Introduction:

Hardboard density is plant fiber as raw materials, processed into density greater than 0.8g/cm of fiberboard, high strength, good workability easy bend, tenon and punch.

According to the panel is divided into one face light hardboard and both face light hardboard.

Structure of products Description:

Plain fiber hard board is made from fresh wood fibre and enviromental glue. We usually use poplar wood, pine wood, eucalyptus wood and other hard wood as raw material to make MDF

board.The thickness of board is from 2mm to 6mm. Standard size of plain MDF is 1220x2440mm. Density from 850m3 to 950kgs/m3. production from Diffenbacher Germany. Surface is very smoothly and density curve is perfect. Low emission of formaldehyde and High density fiber board

Packaging Detail: Loose packing or pallets

Delivery Detail: 14 days after deposit

Specifications of hardboard:

1)Size: 1220*2440*2.5mm~6mm

2)Glue: E0,E1

3)Tolerance of Thickness: +/-0.2mm

4)Material: Poplar and Mix Wood

5)Color: Brown or Dark Brown

6)Density: 950kg/m3~1000kg/m3

7)Face and Back: Smooth and Mesh Pattern

8)Moisture Content: 4%~8%

9)Certificate: ISO9001:2000SGS

10)Bending Strength:33~48Mpa

11)Usage: The Trim of Car,Package,Furniture,Sofa Inside,Photo Frame Back,Baby Carrier,Crib decoration panel and so on

Image:

- Q: What does plywood mean and its synthesis?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: Plywood is a common material for furniture?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- and the general splint or plywood Need, the number of layers is relatively less, in the balance of internal stress

- Q: A brief introduction to plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q: Classification of plywood for construction

- if you want to make outdoor use of wood products, you can use E1 (even E0 level) phenolic plasti

- Q: What is a joinery board?

- The center plate of the blockboard should have the same direction of grain and perpendicular to the texture of the core.

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

- Q: The usual length and width specifications are:

- Solid wood refers to pure solid wood, that is, all materials are not re-processed natural materials, do not use any furniture made of wood furniture.

Send your message to us

15/32 Film Faced Plywood - High Quality Top Sale

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords