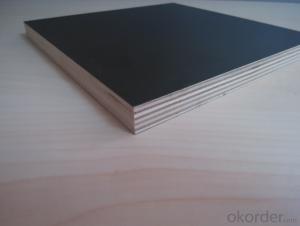

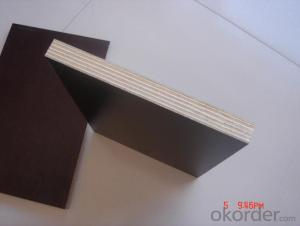

Competitive Plywood Prices - Film Faced Plywood for Building Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

description

Type: Plywoods

Place of Origin: Shandong, China (Mainland)

Brand Name: CNBM

Model Number: 1220 x 2440

Usage: Indoor, construction, Furniture, decoration, packing.

Grade: First-Class

Main Material: Poplar

Formaldehyde Emission Standards: E0

Plywood Type: 7-Ply Boards

Core: Poplar, Hardwood, Hardwood, Combi, Birch, pine,eucalypts

Quantity: 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ

Certificate: ISO9001: 2000; CE; CARB

Min Order: 1X40HC for each size

SPECIFICATION

Size: 1220 x 2440 x 2.5mm

Thickness: 5mm, 9mm, 12mm, 15mm, 18mm

Thickness tolerance: 2.4mm up

Glue: MR, Melamine, WBP Phenolic

Moisture: ≤15%

FEATURE

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. It is good to keep surface warm so in winter the project can also be continued.

3 After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4. The 18mm plywood can be used to make camber and it also can be cut into small pieces according the special requirements.

5. Environmentally friendly.

6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time.

- Q: The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

- Q: What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q: Wood board, plywood, MDF What is the difference

- Can be single-sided sanding, double-sided sanding or both sides are not sanding.

- Q: What is the use of plywood for construction?

- The outermost front panel is called a panel, the back is called a backplane, and the inner board is called a core plate

- Q: Material for the plywood defects which

- Primary rot incipient decay The erosion of the fungus by the growth of the fungus causes a slight change in its chemical composition (usually before drying), showing slight changes in the hardness and discoloration, resulting in changes in the nature of the wood.

- Q: What are the advantages and disadvantages of plywood?

- and then made of adhesive glue from the three or more layers of plate-like material

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

- Q: For the plywood environmental advice?

- E0 is the highest environmental rating. E1 grade glue to do the plywood can be used directly for the interior.

Send your message to us

Competitive Plywood Prices - Film Faced Plywood for Building Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords