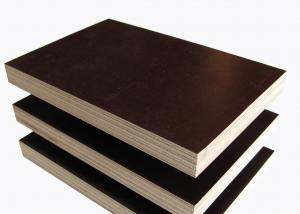

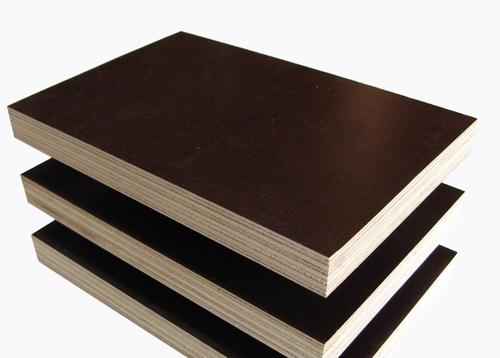

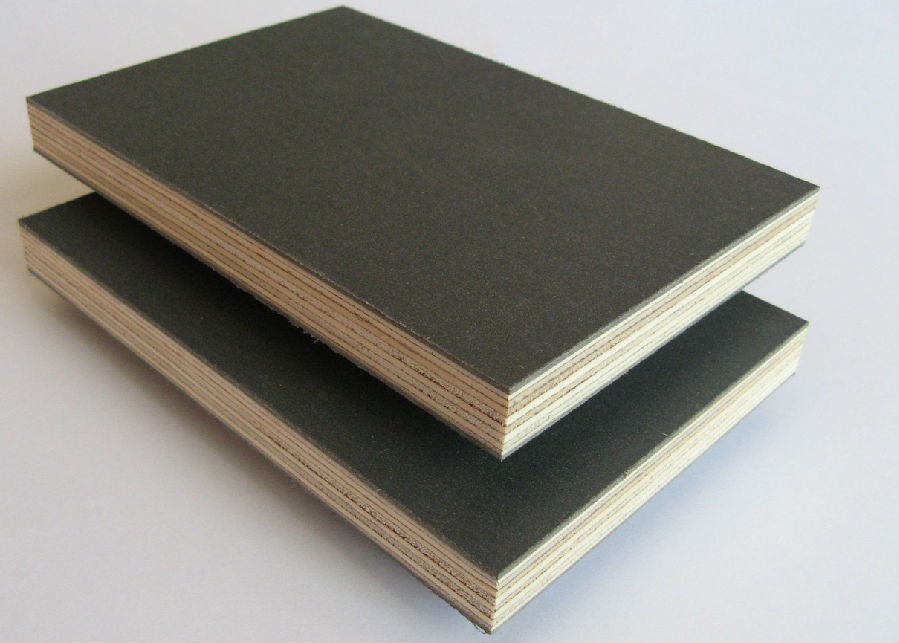

Film Face Plywood with stamp print with best quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Usage: | Grade: | |||

| Main Material: | Formaldehyde Emission Standards: | Plywood Type: | |||

| size: | Glue: | Core: | |||

| F/B: | Thickness: |

Packaging & Delivery

| Packaging Detail: | Inner with waterproof plastic bag, outside with 3mm plywood and carton, then fastened with 3'x6' sheet iron and packed with pallets |

| Delivery Detail: | 15 days after receiving your deposit or LC |

Specifications

15mm film faced plywood for construction

1.Size: 1220x2440/1250x2500mm

2.F/B: Black/Brown/red

3.Core: Poplar, Hardwood

15mm film faced plywood for construction

| Production Description | |||||||||

| Product Name | 15mm film faced plywood for construction | ||||||||

| Size | 1220x2440mm(4'x8'), 1250x2500(4.1'x8.2'), 915x1830(3'x6'), 1500x3000 as per your requirement | ||||||||

| Length/width tolerance | +/-2mm | ||||||||

| Thickness | 8-24mm | ||||||||

| Thickness Tolerance | +/-1mm-+/-0.5mm | ||||||||

| Number of Plies | From 5 to 15 depending on thickness | ||||||||

| Face/Back | Black, Brown, Red, Yellow | ||||||||

| Core | Poplar, Hardwood, Birch, Combined | ||||||||

| Glue | WBP, Melamine, MR | ||||||||

- Q: defects are divided into four grades

- It is generally judged by visualizing the allowable defects on the plywood. The grade depends on the permissible material defects, machining defects, and the requirements for splicing

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- . It can do the floor of the container and other buildings and factories that need to be gravitational, and can be used as a scaffolding. Liquefied gas transport isolation box and so on.

- Q: The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q: What kind of glue is today's plywood?

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde;

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

- Q: What are the shortcomings of plywood

- the plywood is not as smooth as the density of the board, with the plywood to do the grassroots, the surface and then bonding fire board, aluminum panels and other decorative panels, as the density board to do solid base

Send your message to us

Film Face Plywood with stamp print with best quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords