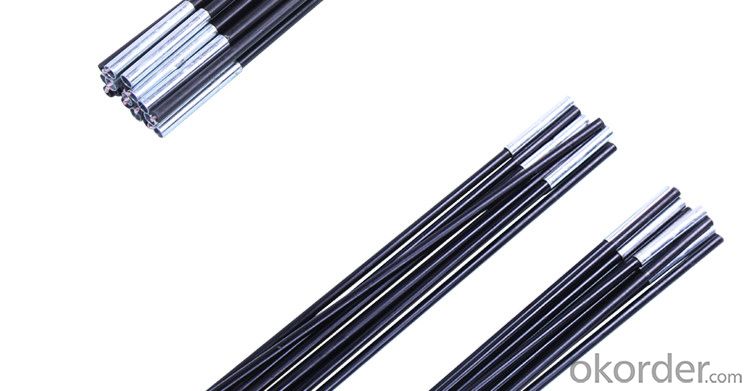

High Quality FRP Pultrusion Profiles Fiberglass Stick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

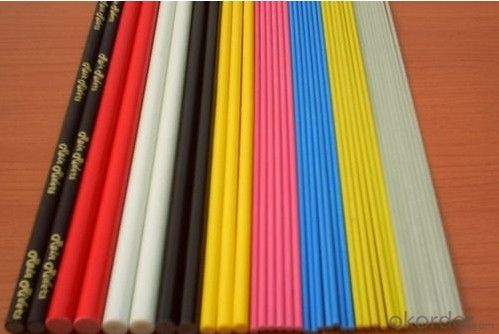

Specifications of Fiberglass Stick with HighQuality:

1. Fiberglass stake

2. Colorful,UV resistant

3. Good flexibility,impact resistant

4. UL,ISO9001,ROHS,

Performance of Fiberglass Stick with High Quality:

|

|

Applications of Fiberglass Stick with High Quality:

|

|

- Q: Can FRP pultrusion profiles be used in the renewable energy sector?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy sector. These profiles possess excellent strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various renewable energy applications. They can be utilized in the manufacturing of wind turbine blades, solar panel frames, structural components for hydroelectric power systems, and much more. Additionally, FRP pultrusion profiles offer design flexibility, allowing for customization to specific project requirements.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP pultrusion profiles are widely recognized for their exceptional ability to withstand oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix creates a material that is naturally resistant to numerous chemicals, including oil and grease. This resistance can be attributed to the non-reactive nature of the polymer resin, which prevents oil or grease from infiltrating the material and causing harm. Moreover, the pultrusion manufacturing process further enhances the profiles' resistance to oil and grease. In this process, the fibers are soaked in the resin and then drawn through a heated die, where the resin solidifies. This results in a sturdy, uniform material with a compact surface that is less porous and more capable of resisting chemical penetration. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the resin used and the conditions of the application. In certain instances, specialized resin formulations can be employed to augment the profiles' oil and grease resistance, ensuring suitability for even the most demanding environments. Overall, FRP pultrusion profiles are widely regarded as highly resistant to oil and grease, making them an exceptional choice for applications exposed to these substances. However, it is always advisable to consult with the manufacturer or supplier to confirm that the specific FRP profile being utilized is suitable for the intended application and chemical exposure.

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- There is a wide selection of FRP pultrusion profiles, which come in various shapes and sizes, to accommodate different applications and industries. Some of the commonly found shapes are as follows: 1. Square and rectangular profiles: These profiles are utilized in construction, infrastructure, and industrial sectors, and they come in different dimensions. They possess exceptional structural strength and can serve as beams, columns, or other load-bearing components. 2. Round profiles: Round FRP pultrusion profiles are frequently employed as structural supports, handrails, and guardrails. They are available in different diameters to suit specific requirements. 3. I-beams: FRP I-beams are well-liked in the construction field because of their high strength-to-weight ratio. They are commonly used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are utilized in applications that demand a combination of strength and versatility. They find use in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: In addition to the standard shapes mentioned above, FRP pultrusion profiles can be tailor-made to meet specific requirements. Manufacturers have the capability to create profiles with unique shapes and sizes that cater to the needs of different applications. It is worth noting that the availability of shapes and sizes may differ among manufacturers. Therefore, it is advisable to consult suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: Can FRP pultrusion profiles be used in the aerospace industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace industry. These profiles offer numerous advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. They can be used in various aerospace applications including structural components, interior parts, and electrical systems. Additionally, their non-conductive properties make them suitable for applications where electrical insulation is required.

- Q: Can FRP pultrusion profiles be used in railway applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in railway applications. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various industries, including railways. In railway applications, FRP pultrusion profiles can be used for a wide range of components such as railway sleepers, bridges, platforms, cable management systems, and even structural support for railway tracks. These profiles offer excellent mechanical properties, including high stiffness and tensile strength, which are crucial for ensuring the safety and integrity of railway infrastructure. Furthermore, FRP pultrusion profiles have low thermal conductivity, making them resistant to extreme temperature variations. This is advantageous in railway applications where exposure to both hot and cold temperatures is common. Another significant advantage of using FRP pultrusion profiles in railway applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode in the presence of moisture or chemicals. This corrosion resistance minimizes the need for regular maintenance and extends the lifespan of railway components, reducing costs in the long run. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes, sizes, and colors, enabling engineers to create tailored solutions for different railway applications. Overall, the use of FRP pultrusion profiles in railway applications provides numerous benefits, including lightweight design, high strength, corrosion resistance, and customization options. These qualities make FRP an attractive alternative to traditional materials and contribute to the overall safety, efficiency, and longevity of railway infrastructure.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals commonly used in mining operations. The composite material used in FRP pultrusion profiles is inherently corrosion-resistant and can withstand the harsh chemical environment typically encountered in mining. Additionally, FRP pultrusion profiles offer excellent resistance to acids, alkalis, solvents, and other chemicals, making them a durable and reliable choice for mining applications.

- Q: How do FRP pultrusion profiles perform in high humidity environments?

- FRP pultrusion profiles perform exceptionally well in high humidity environments. The fiberglass reinforcement in the profiles provides excellent resistance to moisture absorption, preventing any adverse effects on their structural integrity. This makes them highly durable and suitable for long-term use in humid conditions without any significant degradation or damage.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP pultrusion profiles can be used in chemical storage tanks. FRP (Fiber Reinforced Plastic) materials are known for their excellent corrosion resistance and durability, making them an ideal choice for storing various chemicals. The pultrusion process further enhances the strength and structural integrity of the profiles, making them suitable for demanding applications like chemical storage tanks.

- Q: Are FRP pultrusion profiles resistant to chemicals used in power plants?

- Yes, FRP pultrusion profiles are highly resistant to chemicals commonly used in power plants. The composite materials used in their construction, such as fiberglass and resin, offer excellent resistance to corrosion and chemical attack. This makes FRP pultrusion profiles a durable and reliable choice for various applications in power plants, including structural components and equipment.

Send your message to us

High Quality FRP Pultrusion Profiles Fiberglass Stick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords