Composite Fiberglass Reinforced FRP Pipes for Coal Mine Ventilation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Fiberglass Reinforced FRP Pipes for The Coal Mine Ventilate

Company Introduction

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs

in china buiding materials industry. Established in 1984, CNBM is a large group corporation of building materials

with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely

owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

Characteristics

• Corrosion resistance High mechanical property

• Low friction coefficient

• Light weight

• Non toxic

• Maintenance free

• Long life span

• Double O ring sealing joint make the pressurization

more convenient and unique.

• Convenient and quick installation

• Long life of more than 50 years

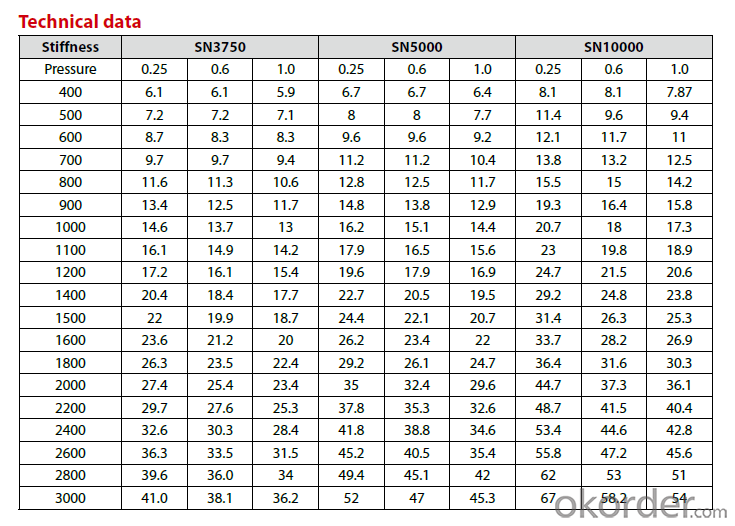

Production range

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced.

Also, we can provide the customized product according to user’s specific requirements.

Application

Due to its own advantages, the RPMP is used extensively in the city engineering water supply and drainage,

the water supply and the drainage or the recycle water in the electric factory, the waste water treatment, the oil

chemical industry and so on.

We will try our best to meet costomers' demands. Welcome you come here to visit us.

We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

- Q: Why FRP pipes for outdoor waste gas treatment equipment are selected?

- Relative to the iron and steel materials such as glass, steel price is the highest, and can reach more than 25 years of life in the outdoors; other materials, such as: PP material, although very similar characteristics of steel and glass, but there is a fatal flaw: the outside is very easy to be corroded and aging, especially direct sunlight high and low temperature conditions, the service life is often less than two years.

- Q: Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- These two parameters are based on the need and the actual geological situation to determine, not a backfill a few meters can be determined.

- Q: Do I need CCC certification for ventilated GRP?

- Of course, there is also used for air conditioning duct glass fiber reinforced plastic pipe, the thickness needs at least 25MM, lined with EPS insulation foam.

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- Glass reinforced plastic sand pipe is mainly to increase the rigidity of the pipe, the relative wall thickness of pure glass steel tube, low compressive strength, shock resistance decreased.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- Other fields such as chemical industry, the product is relatively high, generally aerial or ground, even if there is high pressure, bad high risk, so even high stiffness is thicker instead of sand, in general, not afraid of high investment, the use of pure glass tube, don't use the sand tube.

- Q: What are the materials used in smoke exhaust pipes?

- In the production of the coal mine exhaust pipe is indispensable, in underground work, because from the ground, the air is not easy to reach, easy to accumulate large amounts of methane gas, these gases will need ventilation pipe timely transferred to the ground to prevent the explosion in the coal mine ventilation pipe, the material is generally iron and plastic.

- Q: There is a gap between the new glass fiber reinforced plastic pipe and its through wall. How can the plug be prevented from leaking through the cracks around the pipe?

- Foam with polyurethane, and buy their own back, do it yourself.

- Q: Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- FRP corrosion resistance, high strength (afraid of tanks), light quality, easy to install, socket or flange interface, the price is more expensive than cement

- Q: What are the advantages of FRP pipes?

- Light weight, corrosion resistance, aging resistance, long service life,

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

Send your message to us

Composite Fiberglass Reinforced FRP Pipes for Coal Mine Ventilation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords