Large Diameter Composite Pipes for Hydraulic Transmission - GRP/FRP Pipes on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introdiction

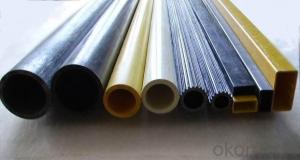

FRP Pultrusion profile is a kind of composite which made by reinforced fiberglass materials (fibers, mat,etc.) and combination withresins and other auxiliary materials(binders). It has very excellent characteristics such as high temperature resistance, corrosion resistance, high strength, light weight, low moisture absorption, good insulating, large-span etc.Pultrusion profiles has very high designability, it can be made into diverse FRP products by appropriate connection and combination of various kinds shaped pultrusion profiles, and it is widely used in different fields such as light industrial products, construction platform, handrail, crawling ladders, pedestrian walkways, cable bridge, cooling tower support, electrotechnical products, etc.We can supply many kinds of FRP pultrusion profile such as Angel beam, I beam, U channel, round tube/rod, square tube, rectangular tube, solid rod, other special shaped profiles etc, and we can also make customized designs.

2.Product Features:

1. High strength.

2. Light weight.

3. Excellent corrosion resistance.

4. Good electric insulating.

5. Fire resistance.

6. Structurally strong.

7. Anti-aging and low maintenance.

8. Easy to fabricate and install.

9. Various Colors available.

10. High designability, can make customized designs.

11. Cost-effective.

3.Specifications

1) adopted the glass fiber and products as its reinforced material,

2)saturated polyester resin as its body material,

materials:

3) adopted the glass fiber and products as its reinforced material,

4)saturated polyester resin as its body material,

5)sand as its filler and equipped with the stipulated length winding technique,

features:

6)lightness and high strength,

7)distinguished properties of water-fast and corrosion resistance,

8)excellent hydraulic property,

9)good hermetical property of joint without poison.

Application:

1) for water -leading projects

2) reduction of the transportation cost and therefore ensured the high quality of the drinkable water.

3)sewage pipes,rainwater pipes

Diameter: DN300-4000

Pressure: PN6-25

Rigidity level: SN2500-10000

Length: 6m, 12m

4.Pultruded Fiberglass Pipe, FRP pipe, GRP pipe of high strengh

The fiberglass reinforced plastic rod is made from high strength glass fibers along withextremely durable resin. The glass fibers impart strength to the rod while the resin impartsexcellent corrosion resistance properties in harsh chemical and alkaline environments.

5.Advantages

1) Long Working life

2) Light weight

3) High strength

4) Good flexibility

5) Beautiful appearance

6)Good Insulation

7) Corrosion resistance

8) Good comprehensive benefits.

- Q: The difference between FRP process tubes and GRP tubes

- Process tubes are mostly pure glass steel, not sand, and sand pipe, of course, is added sand.

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- This depends on the size of the pipe diameter, the greater the diameter, the thicker the wall.

- Q: Mending method for glass fiber reinforced plastic pipe

- Other repair methods: choose resin, accelerator, curing agent, high quality glass fiber cloth. Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, the proportion of the curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth for glass steel with a good quick, let the glass steel glass fiber cloth fully soaked, waiting for glass steel fully cured, and then repeated several layers. It will be strong.

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- Glass reinforced plastic sand pipe is mainly to increase the rigidity of the pipe, the relative wall thickness of pure glass steel tube, low compressive strength, shock resistance decreased.

- Q: Glass tube has different diameters with different prices. Who can elaborate?

- The standard for FRP pipe execution is GB21238-2007

- Q: Which is better, PVC pipe and GRP pipe?!

- Depends on location, and design requirements. Nowadays FRP is in the majority.

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- According to the project of quota valuation mode, input the actual quantity according to the quota item number, the following materials will automatically adjust the quota quota project, has been considering material wastage, when engineering calculation does not need additional.

- Q: Which is better, pultruded FRP square pipe with PVC?

- When a material with higher temperature is conveyed in a wear-resistant pipe, there is a problem that the price of the heat-resistant steel pipe is very expensive. These problems can be easily solved after the wearable pipeline is put on the market. Widely used in wear-resistant pipe wear serious mine filling, ore concentrate and tailings transport, coal-fired power plant powder, slag, ash and other wear-resistant pipe is also very suitable.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Ensure the solidification of glass steel products in a reasonable range, in general, glass fibre reinforced epoxy resin material curing degree if the use of amine curing agent, the best curing degree in the range of 135 degrees --150 degrees, polyester resin, Mohs hardness of about 60 is OK.

Send your message to us

Large Diameter Composite Pipes for Hydraulic Transmission - GRP/FRP Pipes on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords