Fiberglass Pultruded Profile Frp Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiber-reinforced plastic (FRP) (also fiber-reinforced polymer) is a composite material made of a polymer matrix reinforced with fibers. The fibers are usually fiberglass, carbon, or aramid, while the polymer is usually an epoxy, vinylester or polyester thermosetting plastic.

According to customer demand, we can design different functional properties of glass fiber products, carbon fiber products, aramid fiber products and other composite materials products. The scope of products wide range of areas, including: tents, windsurfing, yachting, sports equipment, transportation, communications, electronics, model airplanes, new energy, building materials and other fields.

Create composite materials, composite materials to guide development of the industry total cohesion fiberglass's mission and values.

FEATURES

1.corrosion resistant

2.lightweight,

3.extremely strong and durable

4.mainly used for power&chemical plant

5.high strehght

6.good flexibility

7.aging resistant

8.corrosion resistant

SPECIFICATIONS

Item | FRP | PVC | Aluminum alloy | Steel | Wood |

Tensile strength(mpa) | 350 | 50 | 140 | 290 | 6 |

Tensile modulus(mpa×104) | 4 | 1.6 | 6 | 20 | 0.8 |

Density(g/cm3) | 1.8 | 1.2 | 2.7 | 7.8 | 0.4 |

Thermal conductivity(w/n•0C) | 1.3 | 2 | 220 | 85 | 0.8 |

Coefficient of li near expansion(1/℃) | 0.7×10-4 | 62×10-4 | 22×10-6 | 10×10-4 | 10×10-4 |

Heat resistance(℃) | 130 | 70 | 200 | 300 | |

Appearance | Colorful | ||||

Sevice life(year) | 50 | 15 | 25 | 10 | 10 |

Corrosion resistance | A | B | C | D | E |

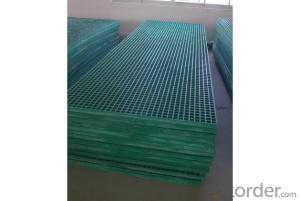

PICTURES

- Q: What are the different types of FRP pultrusion profiles available?

- A variety of FRP pultrusion profiles are available to meet specific application requirements and performance criteria. These profiles include: 1. Standard shapes: These profiles are widely used in various industries and applications. They come in different sizes and shapes, such as round tubes, square tubes, rectangular tubes, and angles. Standard shapes offer versatility and are suitable for both structural and non-structural applications. 2. Custom profiles: These profiles are tailored to customer specifications. They offer flexibility in terms of shape, dimensions, and reinforcement options. Custom profiles are ideal for unique or specialized applications where standard shapes may not suffice. 3. Structural profiles: These profiles are designed for high strength and stiffness. They are commonly used in load-bearing applications, including beams, columns, and trusses. Structural profiles are reinforced with additional fibers to enhance their load-bearing capacity. 4. Electrical profiles: These profiles possess excellent electrical insulation properties. They find application in electrical and electronics applications such as cable trays, busbars, and insulating supports. Electrical profiles offer high dielectric strength and resistivity. 5. Environmental profiles: These profiles are formulated to withstand harsh environmental conditions, including extreme temperatures, UV radiation, and chemical exposure. They are commonly used in outdoor applications like structural supports, handrails, and grating systems. Environmental profiles offer long-term durability and resistance to degradation. 6. Fire-retardant profiles: These profiles are designed to have improved fire resistance properties. They are commonly used in applications where fire safety is crucial, such as building construction, transportation, and aerospace. Fire-retardant profiles incorporate additives that inhibit flame spread and reduce smoke generation. It is important to note that these are just a few examples of the FRP pultrusion profiles available. Depending on specific industry requirements, there may be other specialized profiles. The selection of the appropriate profile depends on factors such as the intended application, load requirements, environmental conditions, and regulatory standards.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q: What is the fatigue resistance of FRP pultrusion profiles?

- The fatigue resistance of FRP pultrusion profiles refers to their ability to withstand repeated or cyclic loading without experiencing failure or degradation over time. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their exceptional fatigue resistance compared to other traditional materials such as steel or aluminum. The fatigue resistance of FRP pultrusion profiles can be attributed to the nature of the composite material itself. FRP profiles are typically made by impregnating continuous fibers, such as fiberglass or carbon fiber, with a polymer resin matrix. This combination of fibers and resin creates a material that exhibits high strength-to-weight ratio, excellent corrosion resistance, and superior fatigue properties. The fiber reinforcement in FRP profiles provides them with inherent resistance against fatigue. The continuous fibers distribute and absorb stresses more evenly, preventing the formation and propagation of cracks or defects that can lead to failure. Additionally, the polymer resin matrix acts as a protective layer, shielding the embedded fibers from environmental factors that could degrade their fatigue resistance. The fatigue resistance of FRP pultrusion profiles can be further enhanced through specific design considerations and manufacturing techniques. For example, the orientation and arrangement of the fibers within the profile can be optimized to improve the load-carrying capacity and fatigue life. Additionally, the use of advanced resin systems and manufacturing processes can result in improved interfacial bonding between the fibers and the matrix, further enhancing the fatigue resistance. Overall, FRP pultrusion profiles are renowned for their exceptional fatigue resistance. This makes them an ideal choice for applications that require long-term durability and resistance to cyclic loading, such as infrastructure components, aerospace structures, marine applications, and sporting goods.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals used in oil refineries. The composition of FRP profiles includes a combination of high-strength fibers, such as fiberglass, carbon fibers, or aramid fibers, embedded in a polymer resin matrix. This unique construction provides excellent resistance to a wide range of chemicals, including those commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully selected to withstand harsh chemical environments. For instance, vinyl ester or epoxy resins are often used in the manufacturing of FRP profiles for oil refinery applications due to their superior chemical resistance properties. Moreover, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete, which can deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Additionally, FRP profiles offer several other advantages in oil refinery applications, including high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is essential to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there might be certain highly concentrated or specialized chemicals that could potentially affect their performance. In such cases, it is advisable to consult with FRP manufacturers or experts who can provide tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

- Q: What raw materials do FRP pultrusion require?

- Fiber: pultruded glass fiber roving, continuous felt, stitch woven felt, stitch woven composite felt, fabric, glass fiber surface mat, polyester fiber surface felt, etc.;

- Q: What are the insulation properties of FRP pultrusion profiles?

- Due to the composition of the materials used, FRP pultrusion profiles possess exceptional insulation characteristics. FRP, an acronym for Fiber Reinforced Polymer, combines the reinforcing strength of fibers with the insulating attributes of the polymer matrix. The insulation qualities of FRP pultrusion profiles chiefly depend on the polymer matrix, which typically consists of thermosetting resins such as polyester, vinyl ester, or epoxy. These resins possess low thermal conductivity, meaning they have poor heat-conducting abilities. This property allows FRP pultrusion profiles to effectively minimize heat transfer via conduction. In addition to their low thermal conductivity, FRP pultrusion profiles also exhibit outstanding electrical insulation properties. The polymer matrix functions as an insulator, preventing the flow of electric current and minimizing the risk of electrical accidents or equipment damage. Moreover, FRP pultrusion profiles demonstrate resistance to moisture, chemicals, and UV radiation, further enhancing their insulation capabilities. Moisture and chemicals can compromise the insulation properties of materials, but FRP exhibits a high level of resistance to these factors, ensuring long-lasting insulation performance. In conclusion, FRP pultrusion profiles offer exceptional insulation properties, making them an ideal choice for applications that require thermal or electrical insulation. They provide a dependable and durable solution for various industries, including construction, electrical, and transportation.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of theme park rides. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing ride structures that need to withstand dynamic loads and forces. Their high strength-to-weight ratio allows for the creation of large, complex structures that can support the weight of riders and withstand the forces generated during operation. Additionally, FRP pultrusion profiles are corrosion-resistant, which is crucial for theme park rides that are often exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures that the ride structures remain durable and safe over their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles is their design flexibility. They can be easily molded into various shapes and sizes to meet the specific requirements of theme park ride designs. This versatility allows for the creation of unique and visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties, which can be essential for rides that involve electrical components or systems. This insulation helps to minimize the risk of electrical hazards and ensures the safety of riders and operators. In conclusion, FRP pultrusion profiles are well-suited for the construction of theme park rides due to their lightweight, high strength, corrosion resistance, design flexibility, and electrical insulation properties. These profiles can contribute to the development of safe, durable, and visually appealing ride structures that enhance the enjoyment and excitement of theme park visitors.

- Q: Can FRP pultrusion profiles be used in the construction of railway platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of railway platforms. FRP profiles are lightweight, durable, and corrosion-resistant, making them suitable for various structural applications. They offer high strength-to-weight ratio, reducing the load on the platform structure while maintaining structural integrity. Additionally, FRP profiles can be customized to meet specific design requirements, providing flexibility in creating efficient and long-lasting railway platforms.

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- FRP pultrusion profiles offer a range of benefits that make them suitable for constructing stadium seating. Firstly, their lightweight yet strong composition is ideal for accommodating a large number of seats. This lightweight feature facilitates easier handling and installation, ultimately saving time and effort during construction. Secondly, FRP pultrusion profiles possess exceptional durability and corrosion resistance, making them well-suited for outdoor applications like stadium seating. Their ability to withstand rust, rot, and degradation from moisture, UV rays, and chemicals commonly found in stadiums ensures a long-lasting seating solution. Moreover, the non-conductive properties of FRP pultrusion profiles provide an added safety advantage, particularly in areas with electrical wiring. This reduces the risk of accidents or electric shocks associated with conductive materials. Additionally, the versatility of FRP pultrusion profiles allows for customization to meet specific design requirements, offering flexibility in stadium seating layouts. They can be manufactured in various shapes, sizes, and colors to align with both aesthetic and functional needs. Lastly, FRP pultrusion profiles boast a long service life with minimal maintenance requirements, resulting in a cost-effective choice for stadium seating in the long term. In conclusion, due to their lightweight, durable, non-conductive, customizable, and cost-effective nature, FRP pultrusion profiles are an excellent option for constructing stadium seating.

- Q: Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. Pultrusion profiles made from fiberglass reinforced plastic (FRP) are manufactured using a combination of resin and glass fibers. The resin used in the manufacturing process is typically formulated to provide resistance to UV radiation. This UV resistance helps to protect the FRP pultrusion profiles from the harmful effects of prolonged exposure to sunlight. FRP pultrusion profiles have been extensively tested and have demonstrated excellent resistance to UV degradation. They are commonly used in outdoor applications where they are exposed to sunlight, such as in construction, infrastructure, and marine industries. UV resistance ensures that the FRP pultrusion profiles maintain their structural integrity, color, and aesthetic appearance over an extended period of time. However, it is important to note that the level of UV resistance may vary depending on the specific formulation of the resin used in the manufacturing process. Different manufacturers may use different resins with varying levels of UV stabilizers. It is recommended to consult with the manufacturer or supplier to ensure that the specific FRP pultrusion profiles being used are designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also important to ensure their long-term UV resistance. This may include cleaning, applying protective coatings, or using UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, ensuring their durability and longevity in outdoor environments.

Send your message to us

Fiberglass Pultruded Profile Frp Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords