Fiberglass Mesh Tape for Plaster - Fiberglass Mesh Roll Reinforcement 4*5

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Mesh Roll Reinforcement 4*5

Fiberglass Mesh Roll Reinforcement 4*5 is mainly alkali-resistant fiberglass fabric, use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

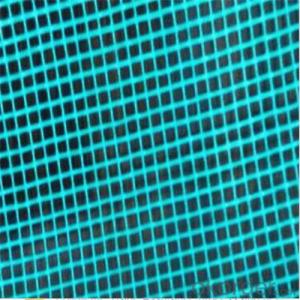

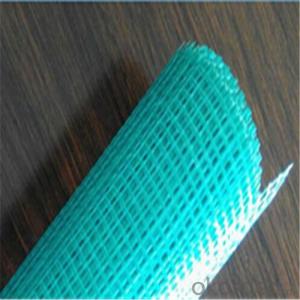

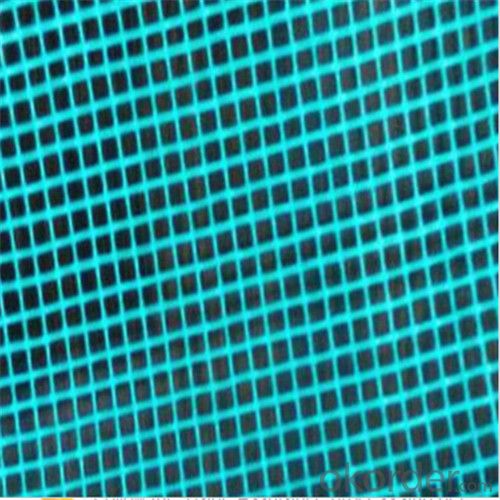

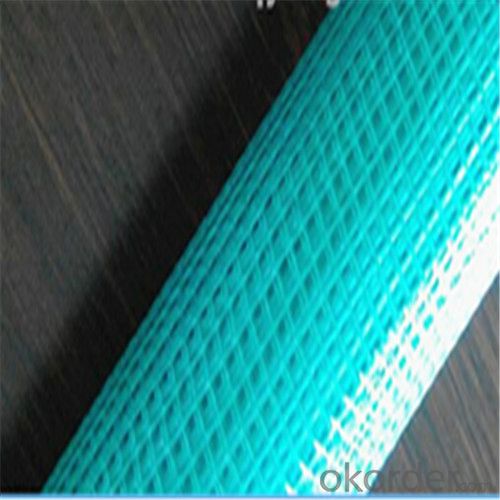

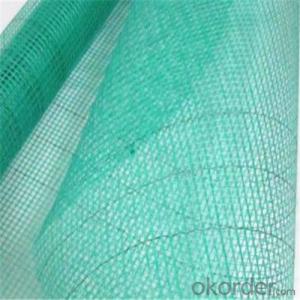

Image of Fiberglass Mesh Roll Reinforcement 4*5

Quick Detail of Fiberglass Mesh Roll Reinforcement 4*5

FOB Price of Fiberglass Mesh Roll Reinforcement 4*5: US $0.21 – 0.32 / Square Meter

MOQ of Fiberglass Mesh Roll Reinforcement 4*5: 5000 Square Meters

Supply Ability of Fiberglass Mesh Roll Reinforcement 4*5: 2000000 Square Meters per Month

Loading Port of Fiberglass Mesh Roll Reinforcement 4*5: CHINA MAIN PORT

Payment Terms of Fiberglass Mesh Roll Reinforcement 4*5: L/C, T/T

Specifications of Fiberglass Mesh Roll Reinforcement 4*5

Fiberglass Mesh Roll Reinforcement 4*5 Place of Origin: China (Mainland)

Fiberglass Mesh Roll Reinforcement 4*5 Brand Name: CMAX

Fiberglass Mesh Roll Reinforcement 4*5 Application: Wall Material, Marble Slab Reinforcement

Fiberglass Mesh Roll Reinforcement 4*5 Width: 1M-2M

Fiberglass Mesh Roll Reinforcement 4*5 Size: 5*5/ INCH, 4*4/ INCH, 4*5/ INCH

Fiberglass Mesh Roll Reinforcement 4*5 Weight: 40gsm to 200gsm

Fiberglass Mesh Roll Reinforcement 4*5 Length/ roll: 50m-100m, Special spec can be customized

Fiberglass Mesh Roll Reinforcement 4*5 Weave Type: Leno, Plain Woven

Fiberglass Mesh Roll Reinforcement 4*5 Yarn Type: C-Glass, E-Glass

Fiberglass Mesh Roll Reinforcement 4*5 Alkali Content: Medium Alkali

Fiberglass Mesh Roll Reinforcement 4*5 Standing Temperature: 500℃

Packing and Delivery of Fiberglass Mesh Roll Reinforcement 4*5

Package: Each Fiberglass Mesh Roll Reinforcement 4*5 roll is wrapped in a shrink bag, then put into containers

Packing Volumes: : 45000-50000m2/ 20FCL, 110000m2/ 40HQ, etc..

Delivery: About 15 days after confirming the order of Fiberglass Mesh Roll Reinforcement 4*5

Application/Usage of Fiberglass Mesh Roll Reinforcement 4*5

A. Wall reinforced material:

Fiberglass wall mesh, GRC wall panels,

EPS insulation with the wall board,

Gypsum board, Bitumen etc

B. Reinforced cement products.

C. Used for Granite, mosaic, marble back mesh etc.

D. Fabric waterproof membrane, asphalt roofing.

E. Framework material for reinforced plastics, rubber products,.

F. Fire board.

G. Grinding wheel base fabric.

H. Road surface geogrid.

I. Construction caulking tape etc.

FAQ of Fiberglass Mesh Roll Reinforcement 4*5

Q: What is Fiberglass Mesh?

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the main application of Fiberglass Mesh Roll Reinforcement 4*5?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh Roll Reinforcement 4*5?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh Roll Reinforcement 4*5?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh Roll Reinforcement 4*5?

A. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

B. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

C. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

D. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

E. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

F. Good impact resistance and not easy to be teared

- Q: How to use gridding cloth tape, namely glass fiber self adhesive tape?

- 1. Keep the wall clean and dry. 2. Paste and press the tape on the crack. 3. Confirm that the gap has been covered with tape, and then cut the needless tape and paint with mortar. 4. Allow it to dry naturally, then polish gently. 5. Fill enough paint in and make its surface smooth. 6. Cut the leak-out tape. Then, check if all the cracks have been properly patched, and decorate the crack with subtle composite material to make it look clean and new.

- Q: Mesh is the same thing with glass fiber cloth ?

- Platinum pot mesh fabric is a mixture of gray fabric knitted by platinum pot yarn and baken plastic, then what is the pot of gold yarn? It is the yarn drawn from pure platinum, then woven into fabric gold pot, combined with glue in the oven under a temperature of 200-500 degrees,and then baken into platinum pot mesh! The quality of pure platinum pot mesh can reach national standards! It looks beautiful and has an even mesh holes. - Di Xiang Mesh in Anping County - it is fireproofing,anti-cracking and heat insulated. It is difinitely the first choice of customers. The industrial glass fiber of pure platinum pot mesh glass fiber products is mainly used for pipeline corrosion, insulation flue {flues}, Continental, light panels, murals sandstone, glass, steel products and other gypsum GRC cement components and insulation board composite plate board walls, etc.

- Q: How to fill in the sample size of glass fiber gridding cloth?

- Alkali resistant gridding cloth specifications: mesh: 5 mm * 5 mm, 4 mm * 4 mm gram weight: 80 g - 160 g / ㎡ length/roll: 50 m, 100 m or 200 m alkali-resistant glass fiber grid cloth features:

- Q: How long does it need to warp fiberglass mesh on window in external wall thermal insulationworks?

- The width of wraping mesh depends on the thickness of thermal insulation boardon the site. The width of pasting on the wall is over 65mm, ang the width of flanging to the board is about 100mm. And the thrown part should be clean.

- Q: excuse me, when fixing the tile on the external wall of six-floors residential building, the thermal insulation board XPS extruded polystyrene board is using the steel mesh or the glass?fiber mesh.

- Both are currently in use, the majority is steel wire, preferably with reference to the implementation of local policies or standards.

- Q: Are epoxy resins and glass fibers the same kind of thing?

- Epoxy resins refer to organic compounds containing two or more epoxy groups in the molecule. Except for some of them, the relative molecular weight of them is not high enough. (two). The molecular structure of epoxy resin is characterized by the presence of active epoxy groups in the molecular chain. The epoxy group can be located at the end of the molecular chain, intermediate or ring like structure. Because the molecular structure contains active epoxy groups, they can react with various types of curing agents to form insoluble polymers with three directions network structure. Any polymer compound with epoxy groups in its molecular structure is collectively referred to as an epoxy resin.

- Q: Is it necessary to add 2 times of alkali resistant fiberglass mesh on the first floor?

- Alkali resistant glass fiber mesh cloth, external wall external insulation layer of reinforced materials, the main role is to: improve the mechanical strength of the surface layer, in order to ensure the continuity of the surface resistance of the surface layer of the dispersed shrinkage of the pressure and stress of insulation, to avoid stress concentration caused by the surface properties and anti crack. The changes of temperature and humidity, unexpected effects. Play an important function and role in the system of the alkali resistant glass fiber mesh insulation, an important part of the selection of the glass fiber net exterior insulation system is also a very good quality.

- Q: When mineral varnish finishing is used for external wall thermal insulation, can fiberglass mesh be used?

- But currently, the quality difference of mesh is quite large in market. You can use mesh to prevent finishing from cracking resulted from uneven stress of plastering mortar and tiny cracks. Bad mesh has little anti-cracking effect.

- Q: Who knows how to use glass?silk mesh?

- Before paving, the wall should be cleaned up, potholes should be patched, an then brush latex and pave meshes on the wall, meshes should be paved smoothly, the interval overlap should be at least 50MM. when the wall is wholly dried up, then move on with next step.

- Q: If fiberglass mesh bent, how to straighten it up?

- First, from the perspective of raw material, it can be divided into the platinum pot and clay pot. Generally the softness and hardness of clay pot products is difficult to control, because clay pot products are generally coated with urea-formaldehyde resin adhesive, while platinum pot products are coated with latex, so its quality is easy to be controlled. Clay pot products only have two states, namely,hard and soft. One is hard, when the product is slightly positioned, but texture is a little brittle, has a poor pulling resistance and easily gets broken off. The other is soft, such products have relatively greater resistance, but are not positioned, so as for the clay pots coated with urea-formaldehyde resin adhesive, their hardness or softness and positioning are mutually contradictory. That is, hard product has better positioning, but possess a smaller tensile force, while soft product has poor positioning, but better tensile force . But as for platinum pot coated emulsion products, their hardness and softness is easy to be controlled, but has to stay within a certain range, the extreme of either is not conducive to construction. To ensure the positioning, the product's hardness and softness in certain range is adjustable, if too hard, the hair nets would be very bad to live with mortar, because a hard product itself has a certain tension, it is difficult to control the mesh. Not soft products in the construction could not be hooked on, so the hardness and softness must be moderate, products with good positioning are easy to be constructed. Just take a trowel with mortar wipe live on the line, if the positioning is not good, when wiping with a trowel, the line will move back and forth, which will affect the overall effectiveness of the insulation and construction.

Send your message to us

Fiberglass Mesh Tape for Plaster - Fiberglass Mesh Roll Reinforcement 4*5

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords