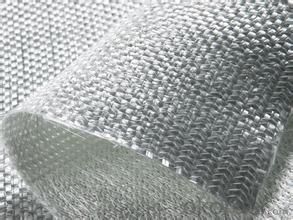

Fiberglass Mat Tissue - E-Glass Fiber Woven Roving Fabric for GRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description Of Products

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Good moldability, fast and complete wet out in resins, resulting in high productivity

Good mechanical properties and high strength of parts

Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

FAQ

Each woven roving is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 220mm. The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass mat tissue safe to handle?

- Fiberglass mat tissue is generally considered safe for handling, but it is crucial to take specific precautions to reduce potential risks. This material consists of delicate glass fibers that, if mishandled, can become airborne and cause skin, eye, and respiratory irritation. To ensure safety, it is recommended to wear personal protective equipment like gloves, safety goggles, and a dust mask while handling fiberglass mat tissue. This will prevent direct contact with the fibers and inhalation of loose particles. Working in a well-ventilated space is also advised to lower the concentration of airborne fibers. Additionally, careful handling is essential to avoid physical injuries. The fibers can be sharp and cause cuts or abrasions if not handled properly. It is advisable to use appropriate tools and techniques when cutting, shaping, or manipulating the material. Proper disposal is equally important when dealing with fiberglass waste. Sweeping or vacuuming the area where fiberglass mat tissue was handled should be avoided, as it can disperse fibers into the air. Instead, opt for damp cleaning methods or specialized vacuum cleaners with HEPA filters to contain the fibers and minimize exposure risks. By adhering to these safety precautions and handling guidelines, the potential dangers associated with fiberglass mat tissue can be effectively minimized, ensuring safe handling and use of the material.

- Q: Is fiberglass mat tissue compatible with different curing methods?

- Indeed, diverse curing methods are compatible with fiberglass mat tissue. This versatile material can be utilized in various curing processes, including hot press curing, autoclave curing, and vacuum bag curing. Specifically engineered to be compatible with different resins and curing temperatures, the mat tissue is capable of enduring the curing process without any detrimental consequences. Furthermore, the mat tissue is designed to possess excellent wet-out properties, enabling it to effectively bond with the resin during the curing process. Ultimately, fiberglass mat tissue proves to be a fitting option for a wide array of curing methods and can be effectively employed in numerous applications.

- Q: How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue performs exceptionally well in terms of moisture absorption. Due to its composition of multiple layers of glass fibers and a binder, it can effectively resist moisture penetration, making it highly resistant to water absorption. This property makes fiberglass mat tissue an ideal material for various applications where moisture resistance is crucial, such as in roofing, insulation, and composite manufacturing.

- Q: Does fiberglass mat tissue require any special maintenance after installation?

- After the installation of fiberglass mat tissue, it typically does not require any special maintenance. Fiberglass mat tissue is designed to be durable and resistant to wear and tear. It is also highly resistant to moisture, chemicals, and UV radiation, making it suitable for various applications such as roofing, insulation, and wall covering. However, it is recommended to inspect the fiberglass mat tissue periodically to ensure it remains in good condition. This can involve checking for any signs of damage, such as cracks, tears, or delamination. If any issues are found, they should be addressed promptly to prevent further damage. Additionally, it is important to follow the manufacturer's guidelines and recommendations for the specific type of fiberglass mat tissue used. This may include avoiding exposure to certain chemicals or using appropriate cleaning methods if necessary. Overall, while fiberglass mat tissue is generally low-maintenance, regular inspections and adherence to manufacturer's guidelines can help ensure its longevity and optimal performance.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Pipe wrapping can indeed utilize fiberglass mat tissue, a lightweight and flexible material extensively employed in reinforcing and safeguarding various structures, including pipes. The primary purpose of fiberglass mat tissue is to enhance the pipes' strength and durability, thereby rendering them more resilient to damage and corrosion. Wrapping the pipe with fiberglass mat tissue is a simple process that creates a protective layer, effectively preventing leaks and prolonging the pipe's lifespan. Moreover, fiberglass mat tissue is renowned for its remarkable insulation properties, contributing to the maintenance of the contents' temperature as they flow through the pipe. Consequently, fiberglass mat tissue serves as a suitable material for pipe wrapping and finds widespread application across diverse industries.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Yes, fiberglass mat tissue can be used for insulation in chemical storage tanks. Fiberglass is known for its excellent insulation properties, making it a suitable material for insulating tanks that store chemicals. The fiberglass mat tissue is typically made from fine glass fibers that are woven together to create a strong and durable material. This mat tissue can be applied to the inner walls of the tank to provide insulation and prevent heat transfer. Additionally, fiberglass is corrosion-resistant and can withstand the harsh chemicals often stored in these tanks, making it an ideal choice for insulation in chemical storage tanks.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q: What is the tensile strength of fiberglass mat tissue?

- Fiberglass mat tissue usually has a tensile strength ranging from 30 to 150 pounds per inch (lb/in). Nevertheless, it is crucial to bear in mind that the precise tensile strength may differ based on the particular type and quality of fiberglass mat tissue utilized.

- Q: What is the shear strength of fiberglass mat tissue?

- The shear strength of fiberglass mat tissue can vary depending on various factors such as the specific type of fiberglass mat tissue, its thickness, and the manufacturing process. However, in general, fiberglass mat tissue typically has a relatively high shear strength due to the inherent strength and rigidity of fiberglass materials.

- Q: What are the different methods of bonding fiberglass mat tissue to other materials?

- There are various ways to bond fiberglass mat tissue to other materials, each with its own advantages and considerations. Some commonly used methods are as follows: 1. Mechanical Bonding: This technique involves physically interlocking the fiberglass mat tissue with the other material. It can be achieved through stitching, stapling, or using mechanical fasteners like screws or nails. While mechanical bonding provides a strong and durable connection, it may require additional hardware and can be time-consuming. 2. Adhesive Bonding: Adhesive bonding is a popular method that utilizes adhesives or glue to join the fiberglass mat tissue with the other material. This method offers flexibility, as there are different types of adhesives available for various applications. It is important to select an adhesive that is compatible with both the fiberglass mat tissue and the other material. Proper surface preparation and application techniques are crucial for achieving a strong bond. 3. Resin Infusion: Resin infusion involves infusing a liquid resin into the fiberglass mat tissue and other materials, resulting in a strong bond when cured. This method is commonly used in manufacturing composite products, as it allows for a seamless and uniform bond. Vacuum bagging or resin infusion techniques are typically employed to ensure proper resin distribution and consolidation. 4. Thermal Bonding: Thermal bonding employs heat to bond the fiberglass mat tissue to another material. This technique is particularly suitable for thermoplastic materials, as they can be softened and fused together with heat. Heat welding or ultrasonic welding are commonly used techniques for thermal bonding. Care must be taken to prevent damage or degradation of the fiberglass mat tissue during the bonding process. 5. Fusion Bonding: Fusion bonding is a method where the fiberglass mat tissue and the other material are heated to a molten state and then brought into contact to form a bond. This technique is commonly used in the manufacturing of thermosetting plastics or joining thermoplastic materials. Fusion bonding can provide a strong and seamless bond, but it requires precise control of temperature and pressure to ensure proper bonding without causing damage. To summarize, the various methods of bonding fiberglass mat tissue to other materials include mechanical bonding, adhesive bonding, resin infusion, thermal bonding, and fusion bonding. The choice of bonding method depends on factors such as the materials being bonded, the desired strength and durability, and the specific application requirements.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiber Woven Roving Fabric for GRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords