Fiberglass Facing Mat for Road Protection - Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mat/ Fiberglass Mat for Road Protection Wholesale Price

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

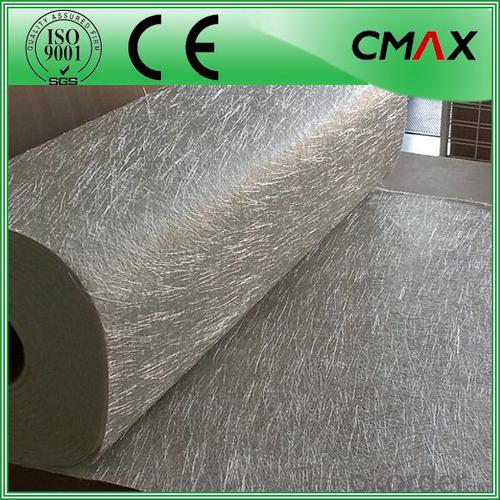

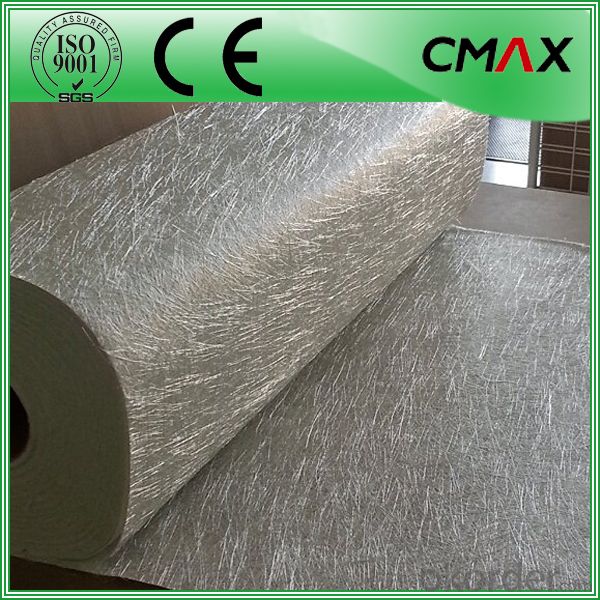

Products Shows:

Certificates:

- Q: Is it possible to utilize black fiberglass tissue for cleaning hard surfaces?

- <p>Yes, black fiberglass tissue can be used as a cleaning tool for hard surfaces. It is known for its durability and abrasive properties, which make it effective in removing dirt, grime, and even rust. However, it's important to use it with caution as it can scratch softer surfaces. Always test a small, inconspicuous area first to ensure it doesn't damage the surface.</p>

- Q: Is it possible to utilize black fiberglass tissue for crafting decorative items?

- <p>Yes, black fiberglass tissue can be used to create decorative elements. It is known for its strength, durability, and flexibility, making it an ideal material for various artistic and design applications. Fiberglass can be molded into different shapes and forms, and its black color can add a sleek, modern touch to any decor. It's often used in combination with other materials to create unique and eye-catching designs, from wall art to furniture accents. However, it's important to handle fiberglass with care due to its potential health risks and to ensure proper ventilation during any cutting or shaping processes.</p>

- Q: What kind of black fiberglass tissue is recommended for use in cold weather conditions?

- <p>Yes, there is a specific type of black fiberglass tissue designed for use in cold climates. This type of fiberglass is often referred to as 'weather-resistant' or 'cold-resistant fiberglass.' It is engineered to maintain its strength and flexibility in low temperatures, preventing brittleness and breakage. This special formulation is crucial for applications where the material will be exposed to freezing temperatures and harsh weather conditions, ensuring durability and longevity.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other organic fibers, focusing on their properties and applications.

- <p>Black fiberglass tissue, also known as black glass fiber, is an inorganic fiber made from glass that is often used for its strength and heat resistance. Compared to organic fibers such as cotton, wool, or silk, black fiberglass tissue is non-flammable, has a higher melting point, and offers superior insulation properties. It is also resistant to chemicals and does not rot or decay. However, it lacks the softness and breathability of organic fibers, making it less suitable for clothing. Organic fibers are biodegradable and more comfortable for direct contact with skin, but they are generally weaker and less heat-resistant than black fiberglass tissue.</p>

- Q: Is the use of black fiberglass tissues safe in residential or commercial settings without taking any specific safety measures?

- <p>While black fiberglass tissues can be used in homes or businesses, it's important to take necessary precautions. Fiberglass is made of fine glass fibers that can be inhaled and may cause irritation to the skin, eyes, and respiratory system. Always wear protective gear such as gloves, goggles, and a mask when handling fiberglass. Ensure proper ventilation to avoid inhaling fibers and clean up carefully to prevent the spread of fibers around the area. Consult material safety data sheets (MSDS) for specific safety instructions related to the product you are using.</p>

- Q: Is the use of black fiberglass scraps considered safe in construction projects?

- <p>The use of black fiberglass scraps in construction work is generally not recommended due to safety and quality concerns. Black fiberglass scraps may contain impurities and inconsistencies that can compromise the structural integrity of the construction. Additionally, they can pose health risks due to the inhalation of fiberglass particles, which can cause respiratory issues. It's crucial to use high-quality, undamaged materials that meet safety standards to ensure the safety of both the construction workers and the longevity of the construction project.</p>

- Q: This question asks for guidance on selecting the appropriate type of black fiberglass tissue for a specific application.

- <p>To choose a suitable type of black fiberglass tissue for your application, consider the following factors: 1) Mechanical properties: Assess the required strength, flexibility, and durability. 2) Thermal resistance: Determine the temperature range your application will encounter. 3) Chemical resistance: Identify any chemicals the tissue will come into contact with and ensure compatibility. 4) Electrical properties: If electrical insulation is needed, check for dielectric strength and resistivity. 5) Optical properties: Black fiberglass may be used for light blocking or aesthetic purposes; consider the desired level of opacity. 6) Environmental conditions: Factor in exposure to moisture, UV radiation, or other environmental stressors. Consult product data sheets and manufacturer recommendations to find a material that meets these criteria for your specific application.</p>

- Q: How should one properly dispose of used black fiberglass tissues to ensure environmental safety and health?

- <p>The best way to dispose of used black fiberglass tissues is to place them in a sealed plastic bag to prevent the release of fibers into the environment. Avoid flushing them down the toilet as this can cause plumbing issues and environmental harm. Instead, dispose of the bag in a regular trash can. If the tissues are contaminated with hazardous substances, follow local guidelines for hazardous waste disposal. Always wear gloves and a mask when handling fiberglass tissues to protect yourself from inhaling fibers or skin contact.</p>

- Q: This question asks about the distinctions among various types of glass fiber paper, which are materials made from thin strands of glass.

- <p>Different types of glass fiber paper are distinguished by their composition, manufacturing processes, and applications. E-glass is the most common and is used for general purposes due to its good electrical insulation properties. S-glass, known for its high strength, is used in applications requiring mechanical strength, such as in aircraft and sports equipment. C-glass is resistant to chemical corrosion and is used in environments with harsh chemicals. A-glass, or alumino-borosilicate glass, is used for applications requiring high temperature resistance. Lastly, D-glass is designed for low dielectric applications, making it suitable for electronics. Each type has unique properties that make it suitable for specific industries and applications.</p>

- Q: Is it possible to use black fiberglass tissue for painting on surfaces?

- <p>Yes, black fiberglass tissue can be used for painting surfaces. It is often used as a substrate for various applications, including painting. To prepare the surface for painting, it should be cleaned thoroughly and possibly primed to ensure proper adhesion of the paint. The type of paint used will depend on the specific requirements of the project, such as durability, weather resistance, and aesthetic preferences.</p>

Send your message to us

Fiberglass Facing Mat for Road Protection - Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords