high temperature resistance fiberglass chopped strand mat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Glass fiber chopped stand mat is kind of glass fiber products which cut by glass fiber strand to the certain length, bonded with power adhesive or emulsion adhesive. The products have higher mechanical strength.

Application:

Thermal insulation and sound-absorb materials for the industrial plant, storehouse, public facilities, exhibition center, market and all kinds of indoor playground.

Product Capability:

Advanced air cleaning, thermal insulation material;

High temperature resistant, good thermal insulation performance, good sound absorption, advanced exhaust gas purity efficiency;

Easy to cut and use;

Antisepsis, aging-resistant, corrosion resistant, ensure the health of environment;

Low moisture absorption, stable physics nature.

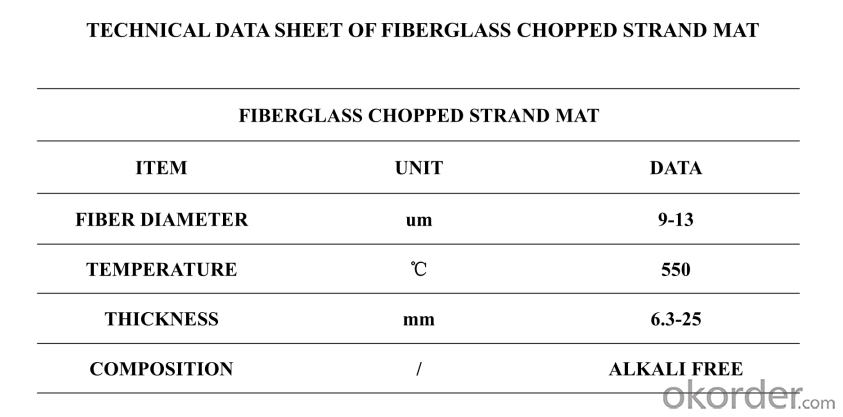

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: How does the fiber dispersion affect the surface finish of chopped strand composites?

- Fiber dispersion refers to the distribution and orientation of individual fibers within a composite material. In chopped strand composites, the fibers are randomly distributed and oriented in various directions. The level of fiber dispersion has a significant impact on the surface finish of the final composite product. When the fibers are well dispersed, meaning they are evenly distributed and oriented, the surface finish of the chopped strand composite tends to be smoother and more uniform. This is because the fibers are able to fill the resin matrix more effectively, resulting in a more homogeneous structure. The smooth surface finish is desirable for applications where aesthetics or smoothness is of importance, such as in automotive or consumer products. On the other hand, poor fiber dispersion leads to uneven distribution and orientation of fibers within the composite. This can create areas with high fiber concentration and other areas with low fiber concentration. As a result, the surface finish of the chopped strand composite becomes rougher and more irregular. The presence of fiber clusters or voids can also lead to surface defects such as pitting or waviness. In addition to affecting the surface finish, fiber dispersion also influences the mechanical properties of the composite. Well-dispersed fibers provide better reinforcement, leading to improved strength, stiffness, and impact resistance. On the contrary, poor fiber dispersion may result in weaker areas with reduced mechanical performance. To achieve a desired surface finish in chopped strand composites, it is important to ensure proper fiber dispersion during the manufacturing process. Techniques such as mechanical mixing, spray-up, or injection molding can be employed to enhance fiber dispersion and promote a smooth and uniform surface finish.

- Q: Is fiberglass chopped strand compatible with thermoplastic resins?

- Yes, fiberglass chopped strand is compatible with thermoplastic resins. Fiberglass chopped strand is commonly used as a reinforcement material in thermoplastic composites. The chopped strands are typically mixed with thermoplastic resins, such as polypropylene (PP) or polyethylene (PE), and then processed using techniques like injection molding or extrusion. The thermoplastic resin melts during processing, allowing the chopped strands to be uniformly distributed throughout the material. This combination of fiberglass chopped strand and thermoplastic resin results in a strong and durable composite material that is widely used in various industries.

- Q: Can fiberglass chopped strand be used in the production of aerospace interiors?

- Yes, fiberglass chopped strand can be used in the production of aerospace interiors. It is commonly used in applications such as insulation, paneling, and reinforcement for lightweight structures.

- Q: Is fiberglass chopped strand compatible with different post-processing techniques?

- Yes, fiberglass chopped strand is compatible with different post-processing techniques. It can be used in various processes such as compression molding, injection molding, and filament winding. The versatility of fiberglass chopped strand allows for its integration into different manufacturing methods and applications.

- Q: Can fiberglass chopped strand be used for reinforcing foam materials?

- Fiberglass chopped strand is capable of reinforcing foam materials, thereby enhancing their strength and durability. By combining the fiberglass chopped strand with foam, the foam material becomes more resilient and less prone to bending or breaking. Consequently, this combination proves advantageous in various applications such as insulation, packaging, and composite materials. The inclusion of fiberglass chopped strand fortifies the foam, resulting in improved structural integrity and overall performance. In addition, the fiberglass chopped strand also bolsters the foam's fire resistance properties, making it a viable option for applications that prioritize fire safety. All in all, utilizing fiberglass chopped strand to reinforce foam materials is an effective and economical means of augmenting their strength and durability.

- Q: How is the weathering resistance of fiberglass chopped strand composites tested?

- The weathering resistance of fiberglass chopped strand composites is typically tested through exposure to various environmental conditions, such as UV radiation, extreme temperatures, moisture, and chemical agents, over a specified period of time. This testing is often done using accelerated weathering chambers or outdoor exposure racks to simulate real-world conditions and determine the composite's durability and resistance to degradation.

- Q: How does the fiber content affect the mechanical properties of fiberglass chopped strand composites?

- The mechanical properties of fiberglass chopped strand composites are significantly influenced by the amount of fiber present. Firstly, the overall strength and stiffness of the composite material are determined by the fiber content. Increasing the fiber content enhances the strength and stiffness as the fibers reinforce the material. These fibers act as load-bearing elements, distributing stress and preventing cracks, leading to improved tensile, flexural, and compressive strength. Secondly, the impact resistance of the composites is affected by the fiber content. A higher fiber content increases the material's ability to absorb energy, making it more resistant to impacts. The fibers act as barriers, absorbing and dispersing impact energy, minimizing damage and crack formation. Moreover, the fiber content also has an impact on the thermal properties of the composites. Fiberglass fibers have low thermal conductivity, meaning they are not good conductors of heat. By increasing the fiber content, the composites become more resistant to heat flow, making them suitable for applications requiring thermal insulation. Additionally, the dimensional stability of the composites is influenced by the fiber content. Higher fiber content reduces the coefficient of thermal expansion, making the material less prone to expansion and contraction caused by temperature changes. This characteristic is particularly important in industries like aerospace and automotive, where dimensional stability is crucial. To summarize, the fiber content in fiberglass chopped strand composites plays a crucial role in determining their mechanical properties. Higher fiber content improves strength, stiffness, impact resistance, thermal insulation, and dimensional stability. It is essential to understand and optimize the fiber content in order to design and manufacture composites that meet specific performance requirements.

- Q: Is fiberglass chopped strand compatible with epoxy resin?

- Yes, fiberglass chopped strand is compatible with epoxy resin.

- Q: How does the moisture absorption of the chopped strand affect its performance?

- The moisture absorption of chopped strand can significantly impact its performance. When moisture is absorbed, it can weaken the structural integrity of the strand, leading to reduced stiffness and strength. Additionally, moisture can cause the strand to swell, which can negatively affect its dimensional stability and lead to delamination or other forms of damage. Therefore, minimizing moisture absorption is crucial to maintain the desired performance characteristics of the chopped strand.

- Q: Can fiberglass chopped strand be used in building and construction applications?

- Yes, fiberglass chopped strand can be used in building and construction applications. Fiberglass chopped strand is a versatile material that offers numerous benefits for construction projects. It is commonly used in applications such as reinforcing concrete, manufacturing composite materials, and insulation. In building and construction, fiberglass chopped strand is often used to reinforce concrete structures. It enhances the strength and durability of the concrete, making it more resistant to cracking and damage. Fiberglass chopped strand can also be used in the production of composite materials, such as fiberglass panels and sheets, which are widely used in construction for their lightweight and high strength properties. Additionally, fiberglass chopped strand can be used as insulation material. It has excellent thermal and acoustic insulation properties, making it suitable for insulating walls, roofs, and floors in construction projects. Fiberglass chopped strand insulation is also fire-resistant and does not release toxic fumes when exposed to high temperatures, making it a safe choice for buildings. Furthermore, fiberglass chopped strand is corrosion-resistant, meaning it can withstand exposure to harsh weather conditions and chemicals commonly found in construction environments. This makes it a reliable material for use in building and construction applications. Overall, fiberglass chopped strand is a versatile material that can be used in various building and construction applications. Its strength, durability, insulation properties, and resistance to corrosion make it an excellent choice for reinforcing concrete, manufacturing composite materials, and providing insulation in construction projects.

Send your message to us

high temperature resistance fiberglass chopped strand mat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords