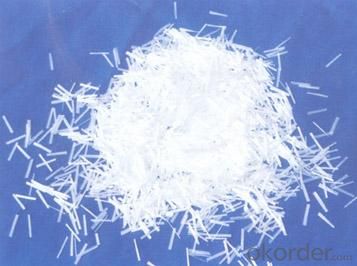

Fiberglass Chopped Strand e-glass Fiberglass for Thermoplastics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

E-Glass Fiber Glass Chopped Strands For Thermoplastics are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How is the surface treatment of fiberglass chopped strand done?

- The surface treatment of fiberglass chopped strand is typically done through a process called silane treatment. Silane is a chemical compound that is applied to the surface of the glass fibers. It acts as a coupling agent, bonding the glass fibers to the resin matrix in the composite material. The silane treatment involves applying a thin layer of the silane compound to the glass fibers. This is usually done through a spray application or by dipping the fibers into a silane solution. The silane then reacts with the surface of the glass fibers, forming a covalent bond. The purpose of the surface treatment is to improve the compatibility between the glass fibers and the resin matrix. Without the treatment, the glass fibers may not bond well with the resin, leading to reduced strength and performance of the composite material. The silane treatment also helps to enhance the adhesion between the fibers and the resin, improving the overall mechanical properties of the composite. It can also increase the resistance to moisture absorption, making the material more durable and long-lasting. In addition to silane treatment, other surface treatments may also be used for fiberglass chopped strand, depending on the specific application and requirements. These can include coatings, finishes, or sizing agents, which further enhance the bonding between the fibers and the resin matrix. Overall, the surface treatment of fiberglass chopped strand is a critical step in the manufacturing process of composite materials. It ensures proper bonding and improved performance, making the material suitable for a wide range of applications in industries such as automotive, construction, aerospace, and marine.

- Q: What are the shear strength properties of fiberglass chopped strand?

- The shear strength properties of fiberglass chopped strand are influenced by several factors, including the length and alignment of the strands, the resin matrix used, and the manufacturing process. Generally, fiberglass chopped strand exhibits good shear strength due to the interlocking nature of the randomly-oriented strands. The length of the chopped strands can have a significant impact on the shear strength. Longer strands tend to provide higher shear strength as they can distribute the applied load over a larger area. However, shorter strands may be preferred for specific applications where improved flow and easier processing are desired. The alignment of the chopped strands also affects the shear strength. Randomly-oriented strands provide better interlocking and resistance to shear forces compared to aligned or unidirectional fibers. The random orientation allows for the distribution of forces in multiple directions, enhancing the overall shear strength of the material. The resin matrix used in fiberglass chopped strand composites also plays a crucial role in determining the shear strength properties. The resin should have good adhesion to the fibers and provide sufficient bonding strength to withstand shear loads. Epoxy resins, for example, are commonly used due to their excellent adhesion properties and high shear strength. The manufacturing process employed to produce fiberglass chopped strand can also impact the shear strength properties. Factors such as the compaction pressure, curing temperature, and post-processing techniques can influence the final shear strength of the material. Careful control of these parameters during manufacturing can optimize the shear strength properties of fiberglass chopped strand. Overall, fiberglass chopped strand exhibits favorable shear strength properties due to the interlocking nature of the strands and the bonding strength provided by the resin matrix. However, it is important to consider the specific requirements of the application and select the appropriate fiber length, alignment, resin matrix, and manufacturing process to ensure optimal shear strength performance.

- Q: How does the fiber alignment affect the electrical conductivity of fiberglass chopped strand composites?

- The fiber alignment significantly impacts the electrical conductivity of fiberglass chopped strand composites. When the fibers are aligned parallel to the direction of the electrical current, the conductivity is improved as the current can easily flow along the path of aligned fibers. In contrast, if the fibers are randomly oriented or misaligned, the conductivity is reduced as the current encounters more obstacles and has a less defined pathway. Therefore, a higher degree of fiber alignment enhances the electrical conductivity of fiberglass chopped strand composites.

- Q: Can fiberglass chopped strand be used for reinforcing concrete structures?

- Yes, fiberglass chopped strand can be used for reinforcing concrete structures. Fiberglass chopped strand is made from fine glass fibers that are randomly chopped into short lengths. These strands can be added to concrete mixtures to enhance its tensile strength, flexural strength, and impact resistance. When mixed with concrete, the chopped strands help to distribute stress loads more evenly throughout the structure, thereby reducing cracking and improving overall durability. Additionally, fiberglass chopped strand is corrosion-resistant, which makes it suitable for use in concrete structures that are exposed to harsh environments or chemicals. Overall, fiberglass chopped strand is an effective and widely used reinforcement material for concrete structures.

- Q: Can fiberglass chopped strand be used in the production of recreational vehicles?

- Yes, fiberglass chopped strand can be used in the production of recreational vehicles. It is commonly used as a reinforcing material in the construction of RV components, such as walls, roofs, and floors, due to its lightweight, high strength, and excellent moldability properties.

- Q: Is fiberglass chopped strand suitable for the production of swimming pools?

- Yes, fiberglass chopped strand is suitable for the production of swimming pools. It is a strong and durable material that has excellent resistance to chemicals and water. Additionally, it can be easily molded into various shapes and sizes, making it an ideal choice for swimming pool construction.

- Q: What are the advantages of using fiberglass chopped strand in the aerospace industry?

- There are several advantages of using fiberglass chopped strand in the aerospace industry. Firstly, fiberglass chopped strand is known for its high strength-to-weight ratio, making it an ideal material for constructing lightweight aircraft components. This characteristic allows for fuel efficiency and increased payload capacity, which are crucial factors in the aerospace industry. Secondly, fiberglass chopped strand offers excellent resistance to corrosion and chemicals, which is essential for aircraft that are exposed to harsh environmental conditions. This resistance ensures the longevity and durability of the components, reducing the need for frequent repairs or replacements. Additionally, fiberglass chopped strand has excellent electrical insulation properties, making it suitable for various electrical applications in aircraft. This insulation characteristic prevents electrical interference and promotes safer and more reliable operation of aerospace systems. Moreover, fiberglass chopped strand is highly versatile and can be easily molded into complex shapes, allowing for intricate designs and customization. This flexibility enables manufacturers to create aerodynamically efficient structures, contributing to improved performance and reduced drag in aircraft. Furthermore, fiberglass chopped strand has low thermal conductivity, making it an excellent choice for insulation purposes. This feature helps to regulate temperature within the aircraft, enhancing passenger comfort and reducing energy consumption. Lastly, fiberglass chopped strand is a cost-effective option compared to other materials used in the aerospace industry. Its availability and ease of manufacturing contribute to lower production costs, making it an attractive choice for aircraft manufacturers. In conclusion, the advantages of using fiberglass chopped strand in the aerospace industry include its high strength-to-weight ratio, resistance to corrosion and chemicals, electrical insulation properties, versatility in design, thermal insulation capabilities, and cost-effectiveness. These benefits make it a preferred material for constructing lightweight, durable, and efficient aircraft components.

- Q: What are the chemical resistance properties of fiberglass chopped strand?

- Fiberglass chopped strand, also known as glass fiber, has excellent chemical resistance properties. It is highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and oils. This is due to the inherent nature of glass fibers, which are composed of inorganic materials that are non-reactive to most chemicals. The chemical resistance of fiberglass chopped strand makes it a popular choice for various applications where exposure to corrosive substances is expected. It is commonly used in the construction industry for corrosion-resistant pipes, tanks, and vessels. Additionally, it is widely utilized in the automotive and aerospace sectors for its ability to withstand exposure to fuels, lubricants, and other chemicals. It is important to note that while fiberglass chopped strand has excellent chemical resistance, it may not be completely immune to all chemicals. Some highly aggressive chemicals, such as concentrated acids or strong oxidizers, may cause limited degradation or affect the mechanical properties of the material over time. Therefore, it is always recommended to consult the manufacturer's guidelines and conduct proper testing when selecting fiberglass chopped strand for specific chemical environments. Overall, the chemical resistance properties of fiberglass chopped strand make it a durable and reliable material for various applications, providing long-lasting performance in corrosive environments.

- Q: How does the electrical conductivity of fiberglass chopped strand affect its performance?

- The overall performance of fiberglass chopped strand heavily relies on its electrical conductivity. Fiberglass is renowned for its superb insulating characteristics, rendering it highly resistant to electrical current. Nevertheless, when fiberglass chopped strand is combined with other substances like resins, polymers, or metals, its electrical conductivity can be significantly altered, subsequently impacting its performance in diverse applications. In situations where electrical conductivity is sought after, such as in manufacturing electronic components or conductive composites, the introduction of conductive additives to fiberglass chopped strand can enhance its electrical conductivity. This modification enables the efficient transmission of electrical current throughout the material, making it suitable for applications that necessitate the conduction of electricity. On the contrary, in instances where electrical insulation is required, the inherent electrical insulating properties of fiberglass chopped strand offer significant advantages. The low electrical conductivity of fiberglass guarantees that it acts as a reliable barrier against the flow of electrical current. This characteristic makes fiberglass chopped strand ideal for utilization in insulation materials, electrical enclosures, or any application where electrical safety is of utmost importance. Furthermore, the electrical conductivity of fiberglass chopped strand can also influence its performance in terms of mechanical strength and durability. In certain cases, the inclusion of conductive materials can impact the bonding and adhesion of the chopped strand to other substances, potentially compromising its overall strength and structural integrity. Conversely, the exceptional electrical insulation properties of fiberglass can contribute to its mechanical strength by preventing material degradation caused by electrical factors like corrosion or electrical discharge. To conclude, the electrical conductivity of fiberglass chopped strand significantly impacts its performance in various applications. Whether high electrical conductivity is needed for efficient conduction or low electrical conductivity is required for effective insulation, comprehending and manipulating the electrical properties of fiberglass chopped strand is crucial in optimizing its performance in specific applications.

- Q: Is fiberglass chopped strand resistant to chemicals?

- Indeed, fiberglass chopped strand typically possesses a high degree of chemical resistance. Comprised of glass fibers and a polymer matrix, fiberglass boasts exceptional durability against a broad spectrum of chemicals. It can endure exposure to a wide array of acids, alkalis, solvents, and other corrosive substances without undergoing substantial deterioration or harm. Nevertheless, the precise chemical resistance of fiberglass chopped strand may fluctuate based on the particular resin employed, the manufacturing procedure, and the specific chemicals employed. It is prudent to consult the manufacturer's specifications or undertake chemical compatibility tests to ascertain the appropriateness of fiberglass chopped strand for a given chemical application.

Send your message to us

Fiberglass Chopped Strand e-glass Fiberglass for Thermoplastics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords