FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic/GRP Door-Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

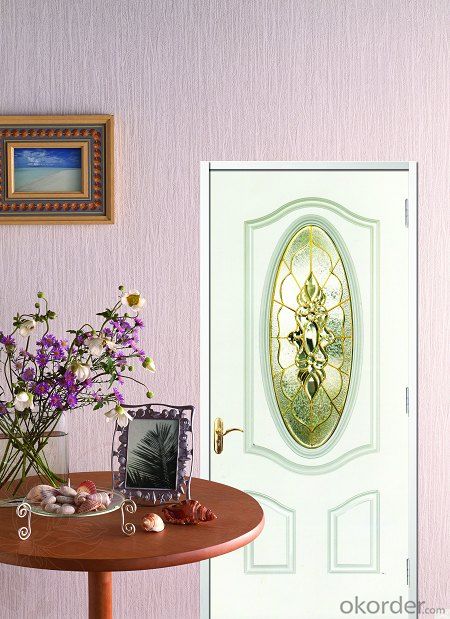

1. Great apperance

2. High intensity

3. Long service life

4.Good sound insulation and heat preservation

5. Customize colors

Product Description

The Advantages of FRP Door &Window

Fiber-reinforced plastic (FRP) (also fiber-reinforced polymer) is compositematerialmading of polymermatrix reinforced with fiber. It’s commonly used inthe aerospace, automotive, marine etc. FRP has distinct advantages that makethem attractive for a wide uses. One of its uses is making FRP doors andwindows. The advantages are:

(1) Excellent water-sealing.Withrain-proof plate, grooves and poles water drainage, doors and windows canisolate rain to outside completely.

(2) Effectual heat preservation. The FRP doors and windows’ heat resistance is almost twice as much as plastic-steeldoors and windows. In winter, it’ll be good temperature keeper, increasing roomtemperature about 5°.

(3) High intensity. It could sustainits own weight, do not bend, fade, distort or rust.

(4)Perfect sound insulation.Withelaborate structure design and rigorous connection, the sound insulation of FRPdoors and windows is below 20db, which is in accordance with DIDN4109.

(5)Easy-maintained.FRP doors andwindows have good resistance to acids, alkalis and waste gas salty substances.They hardly need maintenance, any cleaner made them clean and new as before.

(6)High durability. FRP doors andwindows have long service life, about 50 years, almost same age with the building.

(7) We can customize any color or wooden grain according to your need.We will provide high-quality service, fast delivery and reasonable price,satisfying all your need.

comparing with other

FRP window and door Contrast to Other Materialswindow

Item | Aluminum alloy window /door | PVC window /door | FRP window /door | |

Weight | About 15kg/sq.m | About 8 kg/sq.m | About 6.2kgsq.m | |

Intensity | Tensile strength about 157MPa | Tensile strength about 49.2MPa | Tensile strength about 250MPa | |

Corrosion resistance | Intolerance Hydrogen Fluoride(HF) | Intolerance Hydrogen Fluoride(HF) | Excellent corrosion resistance | |

Insulativity | Good conductor, uninsulate | Have steel liner, bad insulativity | Good insulation and security | |

Durability | Service life less than 20 years. Frangibility | Service life less than 20 years. Frangibility | Service life more than 30 years. Durability | |

Cost | Cheap but high maintenance costs | Expensive and high maintenance costs | Reasonable price | |

Commonality | Over -20°C | -20°C-40°C, in high temperature easy to transfigure. | -40°C-80°C | |

Social benefits | High energy consumption, not environmentally-friendly window | Green product. | Green product |

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of stadium seating. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, which is ideal for stadium seating where a large number of seats need to be installed. The lightweight nature of FRP profiles makes them easier to handle and install, reducing the time and effort required for construction. Secondly, FRP pultrusion profiles are highly durable and resistant to corrosion, making them suitable for outdoor applications like stadium seating. They are not prone to rusting, rotting, or degradation from exposure to moisture, UV rays, or chemicals commonly found in stadiums. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety benefit, especially in areas where electrical wiring may be present. This reduces the risk of electric shocks or accidents that can occur with conductive materials. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in designing stadium seating layouts. They can be manufactured in various shapes, sizes, and colors to match the aesthetic and functional requirements of the stadium. Lastly, FRP pultrusion profiles have a long service life with low maintenance requirements, reducing the overall cost of ownership for stadium seating. This makes them a cost-effective choice in the long run. In conclusion, FRP pultrusion profiles are an excellent choice for the construction of stadium seating due to their lightweight, durable, non-conductive, customizable, and cost-effective nature.

- Q: How do FRP pultrusion profiles perform in corrosive gas environments?

- FRP (Fiber Reinforced Plastic) pultrusion profiles have excellent performance in corrosive gas environments. The unique properties of FRP, such as high corrosion resistance, make them highly suitable for applications where exposure to corrosive gases is a concern. FRP pultrusion profiles are typically made from a combination of glass fibers and a resin matrix, such as polyester or vinyl ester. These materials are inherently resistant to corrosion and do not react with most corrosive gases. As a result, FRP pultrusion profiles can withstand exposure to a wide range of corrosive gases, including sulfur dioxide, hydrogen sulfide, chlorine, and many others. Moreover, FRP pultrusion profiles offer superior durability and long-term performance in corrosive gas environments. They do not rust, corrode, or degrade over time, unlike traditional materials like steel or aluminum. This corrosion resistance ensures that FRP profiles maintain their structural integrity even in harsh environments, reducing maintenance and replacement costs. Additionally, FRP pultrusion profiles can be manufactured with specific chemical-resistant resins and additives to enhance their performance in highly corrosive gas environments. This customization allows for tailoring the FRP profiles to meet the specific requirements of the application, ensuring optimal performance and longevity. Overall, FRP pultrusion profiles are an excellent choice for corrosive gas environments due to their exceptional corrosion resistance, long-term durability, and customization options. They provide a reliable and cost-effective solution for industries such as chemical processing, oil and gas, wastewater treatment, and many others where exposure to corrosive gases is a concern.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can be used in agricultural structures. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages that make them suitable for agricultural applications. Firstly, FRP profiles are corrosion-resistant, which is crucial in the agricultural industry where structures are exposed to harsh environments and chemicals, such as fertilizers and pesticides. Unlike traditional materials like steel or wood, FRP does not rust or decay, ensuring long-lasting performance in agricultural structures. Secondly, FRP profiles are lightweight yet durable, making them easy to handle and install in agricultural applications. They have high strength-to-weight ratios, allowing for efficient construction and reducing the need for heavy machinery during installation. Additionally, FRP profiles offer excellent mechanical properties such as high stiffness and impact resistance, which are beneficial for agricultural structures that may face heavy loads, vibrations, or impact from machinery. Furthermore, FRP pultrusion profiles can be designed to be UV resistant, preventing degradation from prolonged exposure to sunlight. This makes them suitable for outdoor agricultural structures that are constantly exposed to the elements. Lastly, FRP profiles are non-conductive, which is advantageous in agricultural environments where electrical safety is critical. This property eliminates the risk of electrical hazards associated with conductive materials like steel. Overall, FRP pultrusion profiles provide a reliable and efficient solution for various agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them a suitable choice for agricultural applications.

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Certainly, architectural or decorative applications can definitely make use of FRP pultrusion profiles. FRP, an acronym for Fiber Reinforced Polymer, is a composite material that combines sturdy fibers like glass or carbon with a polymer resin matrix. This combination results in a material that is lightweight, durable, and resistant to corrosion, making it ideal for a variety of purposes, including architecture and decoration. The versatility of FRP pultrusion profiles lies in their ability to be manufactured in various shapes and sizes, making them highly adaptable for architectural and decorative uses. These profiles can be utilized to construct visually appealing structures such as columns, beams, and facades, all of which enhance the aesthetic appeal of buildings. Furthermore, FRP pultrusion profiles can be fabricated to imitate the appearance of other materials, such as wood or metal, enabling the creation of decorative elements that seamlessly blend into the overall design. Moreover, FRP pultrusion profiles offer several advantages over traditional materials commonly employed in architecture and decoration. They are lightweight, making them easier to handle and install, reducing labor costs. Additionally, they exhibit high resistance to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Furthermore, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, offering endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable choice for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance guarantees longevity and low maintenance. Whether it is for structural support or decorative embellishments, FRP pultrusion profiles are an excellent option for enhancing the aesthetics and functionality of architectural and decorative projects.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Indeed, FRP (Fiber Reinforced Polymer) pultrusion profiles have the capability to be customized or tailored according to the specific demands of a project. The process of pultrusion, which is employed in the manufacturing, enables the creation of continuous fiber-reinforced composite profiles while providing a considerable amount of design flexibility. By adjusting the design and manufacturing parameters, the dimensions, shapes, and mechanical properties required by a project can be accommodated. The customization procedure commences with a comprehension of the project's needs and specifications. This involves identifying the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can devise a personalized solution. The customization of FRP pultrusion profiles can be accomplished through various methods. Firstly, the selection of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be made based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix utilized in the pultrusion process can be customized to enhance specific properties like fire resistance, chemical resistance, or UV resistance. To meet the project's requirements, different resin systems including polyester, vinyl ester, or epoxy can be utilized. Furthermore, during the manufacturing process, the pultrusion method allows for the incorporation of additional features. This includes the addition of inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. In conclusion, FRP pultrusion profiles offer a significant level of customization and tailoring to cater to the specific demands of a project. This versatility has made them a favored choice in various industries such as construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are essential.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the transportation and logistics industry. FRP pultrusion profiles offer several advantages that make them suitable for various applications in this industry. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in transportation vehicles, such as trucks, trailers, and containers, where reducing weight is crucial for improving fuel efficiency and reducing emissions. Despite their lightweight nature, FRP pultrusion profiles can withstand heavy loads and harsh environmental conditions, ensuring their reliability and longevity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials, such as steel or aluminum, FRP does not rust or corrode when exposed to moisture or chemicals. This makes FRP profiles suitable for use in transportation and logistics applications that involve exposure to corrosive substances, such as saltwater, chemicals, or acidic environments. By using FRP pultrusion profiles, companies can reduce maintenance costs associated with corrosion and prolong the lifespan of their equipment. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of transportation and logistics applications. Whether it is for structural components, platforms, flooring, or supports, FRP profiles can be customized to fit different needs, ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. In the transportation and logistics industry, this can be beneficial for applications such as insulation for refrigerated containers or electrical insulation for specialized vehicles. In summary, FRP pultrusion profiles are well-suited for the transportation and logistics industry. Their lightweight, strong, durable, corrosion-resistant, and customizable nature, along with their electrical and thermal insulation properties, make them a reliable choice for various applications in this sector.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can indeed be used in the telecommunications industry. FRP pultrusion profiles offer several advantages that make them suitable for telecommunications applications. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, which makes them ideal for use in telecommunications infrastructure. These profiles can be used for designing and constructing structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles allows for easier installation and maintenance, reducing the overall cost and effort involved in setting up and maintaining telecommunications systems. Secondly, FRP pultrusion profiles have excellent corrosion resistance properties. This is particularly important in the telecommunications industry, as infrastructure components are often exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, ensuring their longevity and reliability in telecommunications applications. Additionally, FRP pultrusion profiles offer electrical insulation properties, which is crucial in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications where electrical grounding or isolation is required. This feature ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be customized to meet specific project requirements. They can be engineered to have specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the specific demands of each project. In summary, FRP pultrusion profiles are well-suited for use in the telecommunications industry due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Can FRP pultrusion profiles be used in the construction of railway platforms?

- Indeed, railway platforms can be constructed using FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess numerous advantages that render them suitable for this particular application. To begin with, FRP pultrusion profiles exhibit a combination of lightweight and high durability. Consequently, they are well-suited for railway platforms as they can withstand heavy loads and frequent foot traffic without experiencing significant deformation or degradation over time. Moreover, FRP pultruded profiles boast exceptional corrosion resistance. This feature is particularly crucial for railway platforms, which frequently encounter harsh environmental conditions such as rain, snow, and salt. Unlike traditional materials like steel or wood, FRP does not undergo rust or rot, ensuring a longer lifespan for the platform. Additionally, FRP pultrusion profiles offer versatility in design. They can be customized to meet specific dimensional and structural requirements, facilitating the creation of platforms in various shapes and sizes. This adaptability proves beneficial for railway platforms, which often need to be tailored to fit the available space and accommodate specific railway configurations. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties. This attribute is vital for railway platforms, as they necessitate electrical isolation from the tracks to prevent electrical shocks and guarantee passenger safety. Lastly, FRP pultrusion profiles are convenient to install and require minimal maintenance. They can be prefabricated off-site and rapidly assembled on-site, thereby reducing construction time and costs. Furthermore, FRP does not demand regular painting or sealing, resulting in time and cost savings in terms of maintenance. In conclusion, due to their lightweight nature, durability, corrosion resistance, design flexibility, electrical insulation properties, and ease of installation and maintenance, FRP pultrusion profiles serve as a viable option for constructing railway platforms.

- Q: Do FRP pultrusion profiles have any limitations or drawbacks?

- FRP pultrusion profiles indeed have certain limitations and drawbacks that need to be taken into account. One of these limitations is their lower stiffness compared to traditional materials like steel or aluminum. As a result, they may not be suitable for applications that demand high structural rigidity or heavy loads. Another constraint is their susceptibility to creep, which refers to the gradual deformation of the material under a constant load over time. This can adversely affect the long-term performance and durability of the profiles, particularly in scenarios where they face sustained stress. Moreover, FRP pultrusion profiles generally incur higher production costs compared to traditional materials. The manufacturing process involves pultruding continuous fibers through a resin matrix, requiring specialized equipment and expertise. Consequently, the higher production expenses make FRP pultrusion profiles less economically viable for certain applications. Additionally, FRP pultrusion profiles are typically not suitable for high-temperature applications. The resin matrix used in their production can degrade or soften at elevated temperatures, thereby restricting their use in environments where thermal resistance is crucial. Finally, FRP pultrusion profiles may have limited design flexibility compared to other materials. The pultrusion process typically yields profiles with constant cross-sections and limited geometric complexity. Consequently, their use is restricted in applications that necessitate intricate shapes or customized designs. Despite these limitations, FRP pultrusion profiles offer several advantages, such as a high strength-to-weight ratio, corrosion resistance, and electrical insulation properties. Therefore, it is crucial to thoroughly consider the specific requirements of the application before opting for FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP pultrusion profiles can be used in the construction of stadium seating. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength, durability, and corrosion resistance, making them a suitable choice for stadium seating applications. These profiles can be customized to meet specific design requirements and provide a lightweight alternative to traditional materials like steel or concrete.

Send your message to us

FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic/GRP Door-Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords