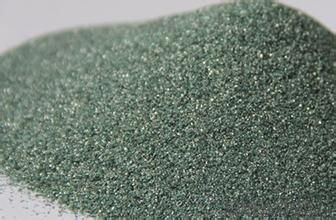

Raw Materials for Refractory:Factory Supply China Green/Black Silicon Carbide SiC F1500 Used for Abrasives and Polishing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon carbide

Products Description

With quartz sand and petroleum coke as its main raw materials, black silicon carbide is produced at high temperature in an electric resistant furnace. Its hardness is between corundum and synthetic diamond and its mechanical strength is higher than corundum, which makes it an ideal material for high quality abrasivetools.

Application

1. The most widely application of silicon carbide is producing abrasive tools, such as grinding wheels, cutting disks, etc. Black silicon carbide powder also could used as lapping and polishing media.

2. Black silicon carbide is suitable for processing glass, ceramics, stone, metal, rubber and other materials. 3. Black carborundum also can be used as metallurgical additive and high-grade SiC refractory material

Color | Black |

Basic Mineral | α-SiC |

True Density | 3.2g/cm3 |

Bulk Density | 1.45-1.56g/cm3 |

Mohs Hardness | 9.2 |

Microhardness | HV3100-3280 |

Chemical Composition of Black Carborundum

Typical Value

SiC | 98.60% |

Fe2O3 | 0.33% |

F. C | 0.16% |

Guarantee Value

Grit Size | SiC | F.C | Fe2O3 |

F12-90 | >98.7% | <0.2%< span=""> | <0.4%< span=""> |

F100-150 | >98.5% | <0.2%< span=""> | <0.4%< span=""> |

F180-220 | >98.0% | <0.3%< span=""> | <0.6%< span=""> |

F230-400 | >97.5% | <0.3%< span=""> | <0.6%< span=""> |

F500-800 | >97.0% | <0.4%< span=""> | <0.8%< span=""> |

F1000-1200 | >96.0% | <0.5%< span=""> | <0.8%< span=""> |

Size Available: Abrasives F16-F1200, P12-2500, JIS#240-JIS#3000 Refractory 0-1mm,1-3mm,3-5mm,200mesh,325mesh Other special specifications could be supplied as required.

We can also supply Green silicon carbide with different particle size F16-F1200 and other size etc.

- Q: Can anyone tell me what is A-leve fireproof material?

- What you say is probably palstic! B-level means the fireproof rating is at B1-level because palstic material doesn't belong to fireproof materials. It only is fire?retardant. When wholesaling all kinds of insulation materials and construction, it need tos look at the names. B1-level refers to the fire endurance rating of the fireproof material, which is determined according to the fire resistance of the material. In addition, different parts of the material have different fire endurance ratings! You can download a "Specifications of Fireproof Design for Buildings" for further information!

- Q: What are the materials of insulation firebricks?

- The furnaces of firebricks are generally divided into two types, namely, unshaped refractory materials and shaped refractory materials. Unshaped refractory materials, also called castables, is a mix of powdery particles of many aggregates and one or multiple adhesives. They must be stirred well with one or multiple liquids when in use, which has a strong liquidity. Unshaped refractory materials generally refers to firebricks. They have standard rules about their shapes and can also be processed temporarily as needed.

- Q: Are fire materials poisonous after burning?

- Refractories burning after the smell of toxic, gases are generally silica, alumina, sulfur oxides and so onRefractory material is not less than 1580 degrees of refractoriness, better thermal shock resistance and chemical erosion, low thermal conductivity and low expansion coefficient of non-metallic materials. Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 94% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, thermal shock resistance is poor. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, refractory material, good heat shock resistance, resistance to acid slag, widely used.

- Q: What is unshaped refractory?

- Concrete。 Early concrete technology appears, it is not forming products in the heat furnace, some parts such as pit heating furnace furnace wall, rotary kiln mouth ring, cutting slope and discharge chamber wall, etc., are able to design large masonry (top heating block weighing 3-4 tons) made concrete. Concrete cattle production method is to pour the material into the model, vibration molding, after the release of heat treatment, to provide users in addition to large blocks, weight, in use, and machine pressure brick no essential difference. The amount of water used in the casting material produced by the manufacturer is less than 10% above that in the field, and the processing quality is good and the quality is stable. As the bricks are large and heavy, the site shall have lifting equipment. As long as the site can be hoisted, the concrete shall be used as far as possible, or smaller ones, and some people can lift it. Concrete does not require the user to do a special heat treatment, this point is very meaningful.

- Q: How to hang the suspended brick in the refractory masonry?

- First you can weld the metal fastener of the suspended brick and then hang up the brick.

- Q: What is the role of the vermiculite fireproof material?

- It can be widely used in construction, decorative ceiling, wall, floor and fireproof door . Especially suitable for airport, railway station, passenger terminal, exhibition hall, hotels, shopping malls, hotels, and other public places and factory, fuel warehouses which have high requirements for fire proofing, etc. With its special thermal insulation, it can also be made to the various types of heat insulation board offered to machines (such as a variety of industrial furnace and assembly line equipment) and furniture, etc. Due to the low density of the product itself, a lot of shipyards in foreign countries use it as ceiling, wall and deck, so the development potential of the domestic shipbuilding market is huge.Expanded vermiculite is porous, lightweight, and dystectic, the most suitable for insulating materials at high temperature (below 1000℃) and fire insulation materials. In the experiment, 15cm- thick cement vermiculite burns for 4-5 hours under 1000℃, but the back temperature is only 40℃. 7 cm-thick vermiculite slate burns for 5mins through the fire flame welding net under 3000℃, the frontage melted, but you don’t feel hot with your hands holding the back side. According to aforementioned, vermiculite slate is superior than all insulating material, such as asbestos, and diatomite products.

- Q: How to apply the alumina powder on refractories?

- The most common one in use is the refractory bricks.

- Q: Who can introduce the external wall thermal insulation materials fire rating regulations?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3 combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q: which is better as household fireproof material ?

- the thickness recommended is 1mm or more # 304 stainless steel plate, refractory corrosion-resistant, easy to clean. It now appears that among the most common fireproof material, asbestos is the best. But the asbestos harmful effect is also great, especially for lung damage. Now on the market, the polyurethane, polystyrene, rock wool glass wool, phephenolic aldehyde fireproofingthermal insulation board. But now the phenolic aldehyde fireproofing thermal insulation board has superior performance! phenolic aldehyde containing only carbon, hydrogen and oxygen atoms, when subjected to pyrolysis, except small amounts of CO gas, the other will not produce toxic gases, maximum smoke density is 5.0%.

- Q: Which basic refractory is better?

- 1 Zibo Quanxing Refractories Plant, factory direct, quality assurance, best price, off the shelf. 2 Zibo Huadian Refractories Co.,Ltd. one package service from research, production, sale to construction, our trust!

Send your message to us

Raw Materials for Refractory:Factory Supply China Green/Black Silicon Carbide SiC F1500 Used for Abrasives and Polishing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords