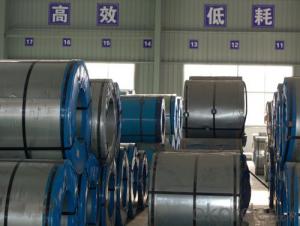

excellent cold rolled steel coil -SPCE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed

6. Margin Status: EC & EM

7. Surface Quality: FB&FC

8. Surface Status: SB & SD

9. Surface Treatment: Oiling

Main Features:

1. Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand.

2. Drawing quality second only to that of SPCEN. Excellent uniformity.

3. Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn.

4. Extra-low-carbon steel sheets with highest workability

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Images:

Quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many rocessing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing

- Q: I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- I have steel siding, and it is a pain in the butt. It's much harder to keep clean than vinyl. As for color combos, I love mine, sunny yellow with off white trim, and brick red for the doors. I added new brushed chrome doorknobs and brushed chrome rails around the porch, and it looks awesome. I am planning to have the steel siding replaced with vinyl though.

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- Stainless Steel Throwing Knives

- Q: What are the common standards and specifications for steel coils?

- In the industry, there are various widely recognized and utilized standards and specifications for steel coils. Some notable ones include: 1. ASTM A36/A36M: This specification is concerned with carbon structural steel shapes, plates, and bars of structural quality. It is intended for use in constructions that involve riveting, bolting, or welding. 2. ASTM A572/A572M: This specification focuses on high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It is applicable for constructions involving bolting, riveting, or welding. 3. ASTM A653/A653M: This specification pertains to steel sheet that is zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) through the hot-dip process. 4. ASTM A1011/A1011M: This specification covers various types of steel sheet and strip in coils, such as hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet, also known as galvanized steel sheet, and strip. 6. EN 10111: This European standard outlines the requirements for continuously hot-rolled low carbon steel sheet and strip that are suitable for cold forming. 7. ISO 3575: This International Organization for Standardization standard lays down the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few instances of the prevalent standards and specifications employed for steel coils. It is crucial to note that different industries and applications may have specific demands, thus consulting the relevant standards and specifications for the particular application is always advisable.

- Q: Are steel coils used in furniture manufacturing?

- Yes, steel coils are commonly used in furniture manufacturing. They are often used as a support system in upholstered furniture such as sofas and mattresses to provide stability and comfort.

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- Yes, most definitely. Just make sure it's full and don't have air inside lol. You can tell it's full by it being heavy. I've seen bullet tests on TV and I'm like 100% positive it's gonna withstand. But no, you can't use it as bullet-proof vest, because it's HEAVY!! You can see on Youtube. 1 inch legitimate steel would stop even a 50 cal

- Q: How do steel coils contribute to the aerospace industry?

- The aerospace industry benefits greatly from the utilization of steel coils. They serve multiple purposes in this field. Firstly, they are instrumental in the production of aircraft structures and components. Steel coils can be transformed into various forms, such as sheets or plates, which can then be shaped and welded to create essential parts of an aircraft, including wings, fuselage, and landing gear. The exceptional strength and durability of steel make it an optimal material for such critical components, guaranteeing the safety and dependability of the aircraft. Secondly, steel coils play a pivotal role in the manufacturing of jet engines. The extreme conditions and high temperatures that engines endure necessitate materials with outstanding heat resistance and mechanical properties. Steel coils, especially those made from alloys like stainless steel or nickel-based alloys, possess the requisite attributes to withstand the demanding environment within a jet engine. These coils can be processed into turbine blades, exhaust system components, and other engine parts, thereby enhancing the overall performance and efficiency of the aircraft. Furthermore, steel coils find utility in the construction of aerospace infrastructure and ground support equipment. Strong and durable materials are essential for ensuring the stability and longevity of structures like hangars, maintenance facilities, and launch pads. Steel coils are frequently fabricated into beams, columns, and other structural elements that form the foundation of these facilities, providing the necessary strength to withstand the various loads and vibrations associated with aerospace operations. In conclusion, the aerospace industry heavily relies on steel coils due to their indispensable qualities of strength, durability, and heat resistance. These coils contribute significantly to the manufacturing of aircraft structures, engine components, and aerospace infrastructure, thereby guaranteeing the safety, performance, and reliability of aircraft. This, in turn, facilitates the advancement of aviation technology and enables the exploration of new frontiers in aerospace.

- Q: I need to know a name of any site which provides information on Steel structures??

- www.okorder /

- Q: What are the different types of steel coil storage containers?

- There are several types of steel coil storage containers, including coil racks, coil cradles, coil saddles, coil cassettes, coil pallets, and coil cones. These containers are designed to safely store and transport steel coils, providing support and stability to prevent damage or shifting during handling and storage.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they can be formed into various shapes and sizes to create the enclosure's structure. The coils are typically cut, bent, and welded together to form the walls, base, and lid of the enclosure, providing a sturdy and protective housing for electrical components.

- Q: How are steel coils used in the production of metal bridges?

- Due to their versatility, strength, and durability, steel coils are a crucial element in the manufacturing of metal bridges. These coils, typically made from high-quality steel alloys, provide the necessary structural integrity required for bridge construction. To begin the process of using steel coils for bridge production, they undergo a series of manufacturing techniques. The coils are uncoiled and straightened to eliminate any distortions or bends. They are then precisely cut into lengths according to the specifications of the bridge design. Once the steel coils have been processed, they are transformed into various structural components used in bridge construction. These components include beams, girders, trusses, and plates. Beams and girders serve as the primary support structure of the bridge, while trusses provide additional support and stability. Plates are used for the bridge deck, providing a surface for vehicles and pedestrians to travel on. Steel coils also play a critical role in the fabrication of bridge connections and joints. These connections are essential for transmitting loads and forces throughout the bridge structure, ensuring its stability and safety. Steel coils are utilized in the creation of various connection elements, such as bolts, nuts, washers, and welded sections. Furthermore, steel coils are commonly employed in the production of bridge reinforcements. Rebar, which is used to strengthen concrete elements within the bridge, is manufactured from steel coils. By enhancing the load-bearing capacity and resistance to bending and tension, these reinforcements strengthen columns, piers, and abutments. In addition to their structural applications, steel coils are also utilized for protective coatings on metal bridges. They can be coated with specialized materials like zinc, epoxy, or paint to prevent corrosion and extend the bridge's lifespan. These coatings are especially important in harsh environments with high levels of moisture, chemicals, and weathering factors, as they help maintain the bridge's structural integrity. Overall, steel coils are the foundation of metal bridge production. They are transformed into various components, connections, reinforcements, and protective coatings that ensure the bridge's strength, durability, and longevity.

Send your message to us

excellent cold rolled steel coil -SPCE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords