ERW oil Tubes Welded Steel Pipe Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.5 - 14 mm | Section Shape: | Round | Outer Diameter: | 21 - 219 mm |

Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | Cold Rolled | Certification: | ISO | Surface Treatment: | oiled |

Special Pipe: | EMT Pipe | Alloy Or Not: | Non-alloy | Wall thickness: | thin wall pipe |

| Grade: | Q195,Q195-Q345 | Standard: | BS ,JIS G3101,DIN 2444,BS,JIS,DIN,API 5L |

1、Structure of Seamless Pipe ASTM A106/53:

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

Payment Terms: L/C D/A D/P T/T

Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

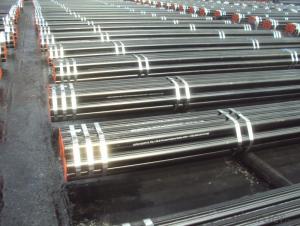

6、Seamless Pipe ASTM A106/53 Images:

- Q: What are the different methods of testing steel pipes?

- There are several methods used for testing steel pipes, including visual inspection, ultrasonic testing, radiographic testing, magnetic particle testing, and hydrostatic testing. Visual inspection involves examining the pipes for any surface defects or abnormalities. Ultrasonic testing uses sound waves to detect flaws or inconsistencies within the pipes. Radiographic testing involves using X-rays or gamma rays to produce images of the pipes and identify any defects. Magnetic particle testing uses magnetic fields and magnetic particles to detect surface or near-surface defects in the pipes. Hydrostatic testing involves pressurizing the pipes with water to ensure they can withstand the specified pressure without leaks or failures.

- Q: What are the different types of threading on steel pipes?

- The different types of threading on steel pipes include tapered threads, straight threads, and buttress threads. Tapered threads are commonly used for pipes that will be screwed into fittings, while straight threads are typically used for pipes that will have a coupling or union attached. Buttress threads are designed for heavy-duty applications and provide increased strength and resistance to axial loads.

- Q: Can steel pipes be used for conveying sewage sludge?

- Yes, steel pipes can be used for conveying sewage sludge. Steel pipes have several properties that make them suitable for this purpose. Firstly, steel pipes are strong and durable, able to withstand the pressure and weight of sewage sludge without collapsing or breaking. This is important as sewage sludge can be heavy and contain solids that may put stress on the pipes. Secondly, steel pipes are resistant to corrosion, which is crucial when conveying sewage sludge that often contains corrosive elements. Corrosion-resistant steel pipes can ensure a longer lifespan and minimize the risk of leaks or damage. Additionally, steel pipes can be manufactured in various sizes and diameters, allowing for flexibility in designing sewage systems to meet specific requirements. However, it is important to note that proper maintenance and regular cleaning should be carried out to prevent the buildup of sludge and maintain the efficiency of the pipes.

- Q: Can steel pipes withstand high temperatures?

- Yes, steel pipes can withstand high temperatures as they have a high melting point and excellent heat resistance properties, making them suitable for various industrial applications involving high temperature environments.

- Q: How do steel pipes connect to other components?

- Steel pipes can be connected to other components using various methods such as welding, threading, flanges, or couplings.

- Q: What is ND steel pipe?

- ND steel 09CrCuSb steel is currently the most ideal "resistance to sulfuric acid dew point corrosion in steel (ND steel, ND steel, 09CrCuSb steel, 09CrCuSb steel), ND steel is widely used in the manufacture of economizer, served in the high sulfur content in flue gas of air preheater, evaporator and heat exchanger equipment for resist sulfur smoke gas dew point corrosion.

- Q: What are the different types of steel pipe fittings for chemical processing plants?

- There are several types of steel pipe fittings commonly used in chemical processing plants, including elbows, tees, reducers, flanges, and valves. Elbows are used to change the direction of the flow, tees are used to combine or split the flow, reducers are used to connect pipes with different diameters, flanges are used for connecting pipes and valves, and valves control the flow of fluid within the system.

- Q: Can steel pipes be used for high-pressure applications?

- Yes, steel pipes can be used for high-pressure applications. Steel pipes are known for their strength and durability, making them suitable for handling high-pressure fluids, gases, or steam in various industries such as oil and gas, construction, and manufacturing. They are designed to withstand the high internal pressure and are commonly used in pipelines, steam systems, and hydraulic systems where the pressure requirements are significant.

- Q: What does carbon seamless steel pipe mean? What is the difference between a seamless 20# and an ordinary one? What is it used in detail?

- Carbon steel is relatively alloy steel. Its carbon content is higher than alloy steel, and 20# steel is one kind of carbon steel.

- Q: What are the advantages of using steel pipes over other materials like PVC or copper?

- There are several advantages of using steel pipes over other materials like PVC or copper. Firstly, steel pipes are extremely durable and can withstand high pressure and extreme temperatures, making them ideal for various applications including industrial and underground use. Secondly, steel pipes have a longer lifespan compared to PVC or copper, reducing the need for frequent replacements and maintenance. Additionally, steel pipes are more resistant to corrosion and are not prone to cracking or leaking, ensuring a reliable and leak-free plumbing system. Lastly, steel pipes have a higher fire resistance rating compared to PVC, making them a safer option for certain environments.

Send your message to us

ERW oil Tubes Welded Steel Pipe Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords