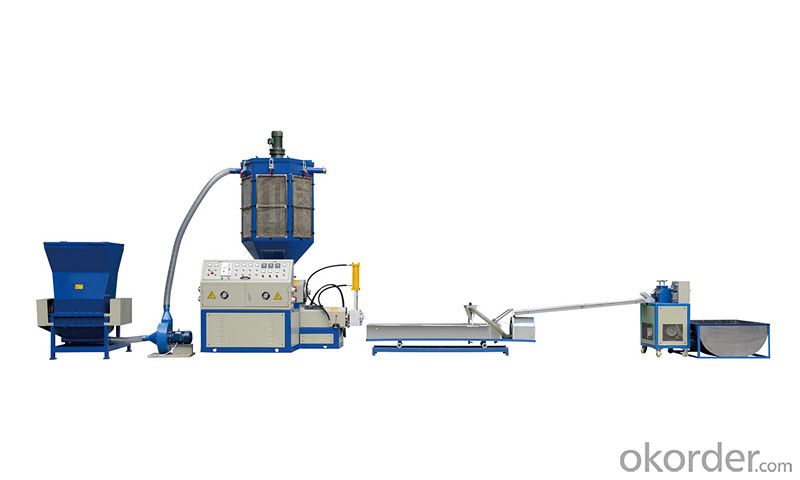

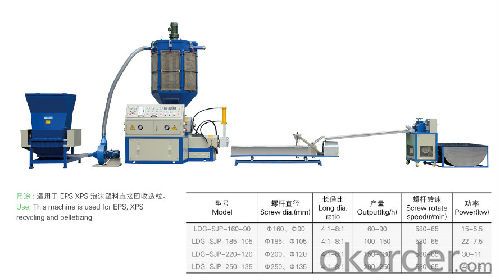

EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Use of EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

This machine is used for EPS ,XPS recycling and pelletizing, especially for sorting materials and transform rubbish into treasure. It is an ideal choice for environmental protection of the supermarket and the utility areas.

Features of EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

The machine adopt the fast compact , fast melting , extruding with filter , whole line design to recycling the material into the granules.The hole diameter of stamped sieve plate can be custom-made according the user's requirements.motor:15kw output:60-90kg/h

Packaging & Delivery

| Packaging Details: | Packed in wooden case,side screw force feeder pelletizing line |

|---|---|

| Delivery Detail: | Delivery Within 30-45 Working Days,side screw force feeder pelle |

Kindly feel free to contact with me if you need more detail informations.

And if convenience for you,welcome to visit our factory to know more about our machine.

- Q: which is most suitable for tearing off the steel in the cutting and grinding process?

- It is possible to damage the film before cutting, cutting and edging

- Q: Laser cutting plastic film after the edge is difficult to separate, how to solve?

- What kind of marble, aluminum and alloy platforms are available?. Depends on how you want to do the material to choose the platform. Marble platform is generally not recommended, as long as there is no hollow, are solid surface material, put it up a few times, it will stick on the platform.

- Q: What tools are used for cutting plastics?

- The laser cutting machine is the best and the most widely used non metal cutting machine.

- Q: What tools can easily cut plastic cardboard? What's the name of the tool?

- Manual cutting machine, decoration cut wood strips, electrical engraving groove, just grinding wheel pieces are not the same, less angle grinder available

- Q: Ladies and gentlemen, what tools are used for cutting plastic shells, such as round shaped ones?

- The copper wire will burn. If the temperature is not enough, continue to add batteries.

- Q: Is there a little black gas, poisonous gas? Choose a dustproof mask or a gas mask?

- Toxic. Wear a mask with activated carbon, because activated carbon can absorb toxic gases

- Q: How about cutting the plastic block?

- Direct grinding, re engraved, the general teacher Fu will not make mistakes, not to mention, now are electronic engraved chapter

- Q: What materials can be cut by laser cutting machine?

- Zhejiang Leili cold drying machine, dryer, rotary oil-water separator no heat regenerative adsorption dryer tepefaction regeneration adsorption dryer

- Q: What saws are used for cutting plastic pipes? What kind of saws are universal and what are they sold by?

- Woodworking saw is that kind of round with teeth, the first measure of good size, buy or not loaded, hardware stores should have, if the planet saw that kind of saw, only in the cutting machine manufacturers to buy the market does not have

- Q: How to use plastic cutters to seal cartons?

- With the blower's hot air blowing on the tape, it seems to be a lot easier, but the premise is that your belt quality can not be very good, and the other is that the quality of the surface of the carton should be good enough, if there are wrinkles, what is not estimated ~ ~!

Send your message to us

EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords