Epoxy Resin E51 128 220kgs/Barrel Bisphenol A Liquid Epoxy Resin Building Adhesive

1 - 4 PCS

US$1220

5 - 9 PCS

US$1200

>= 10 PCS

US$1180

- Loading Port:

- Guangzhou

- Delivery Time:

- 20 days after your payment

Option:

- Quantity:

- Shipping:

- Freight Cost Calculator

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Epoxy Resin E51

Basic Information:

Material:Epoxy Resin

Color: Transparent

Shelf Life: 12 Months

Model Number:E51

MOQ:220kgs/Barrel

Payment Terms: L/C T/T Credit Card

Production Description

Epoxy resin E51 is a bisphenol A liquid epoxy resin, which belongs to basic epoxy resin and is a low toxic, colorless or yellowish viscous liquid. It is mainly used for bonding, casting, sealing, impregnation, lamination and other fields. It can also be used as raw material for epoxy resin processing. It accounts for a large proportion in the application of coatings. The solvent-free or less solvent-free coatings prepared by epoxy resin have strong corrosion resistance, and have little environmental sludge during construction. It coatings are mainly used as anti-corrosion paint, metal primer and insulating paint. Its commonness:

1. Good chemical resistance, especially alkali resistance.

2. The paint film has strong adhesion, especially to metal.

3. It has good heat resistance and electrical insulation.

4. The paint film has good color retention.

Application

1. Pouring of insulation packages for electrical appliances and motors: manufacturing of overall fully sealed insulation packages for high and low voltage electrical appliances such as electromagnets, contactor coils, transformers, dry-type transformers, etc. It has developed rapidly in the electrical industry. It has developed from normal pressure pouring and vacuum pouring to automatic pressure gel forming.

2. Epoxy resin 128 is widely used for encapsulation and insulation of devices with electronic components and circuits. It has become an indispensable and important insulating material in the electronic industry.

3. Electronic grade epoxy molding compound is used for plastic packaging of semiconductor components. It has developed very fast in recent years. Because of its superior performance, it has a great tendency to replace the traditional metal, ceramic and glass packaging.

3. Epoxy laminated plastic is widely used in electronic and electrical fields. The development of epoxy copper clad laminate is particularly rapid, and it has become one of the basic materials in the electronic industry. In addition, epoxy insulating coatings, insulating adhesives and electrical adhesives are also widely used.

4. Engineering plastics and composite materials: epoxy engineering plastics mainly include epoxy molding materials, epoxy laminated plastics and epoxy foam plastics used for high-pressure molding. Epoxy engineering plastics can also be regarded as a kind of generalized epoxy composite materials. Epoxy composites mainly include epoxy glass fiber reinforced plastics (general composite) and epoxy structural composites, such as pultruded epoxy profiles, wound hollow rotary products and high-performance composites. Epoxy composite is an important structural and functional material in chemical industry, aviation, aerospace, military and other high-tech fields.

5. Civil materials are mainly used as anti-corrosion floor, epoxy mortar and concrete products, high-grade pavement and airport runway, quick repair materials, grouting materials for strengthening foundation, building adhesives and coatings, etc

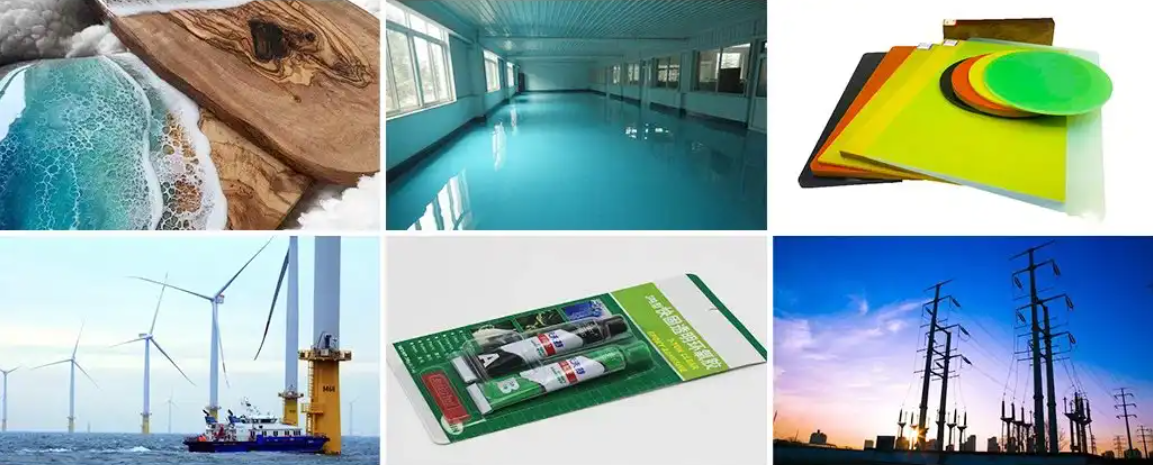

1. Ornament Splice 2. Floor Coating 3. Insulation Material

4. Wind Power Blade Plate 5. A B Glue 6. Electrical Industry

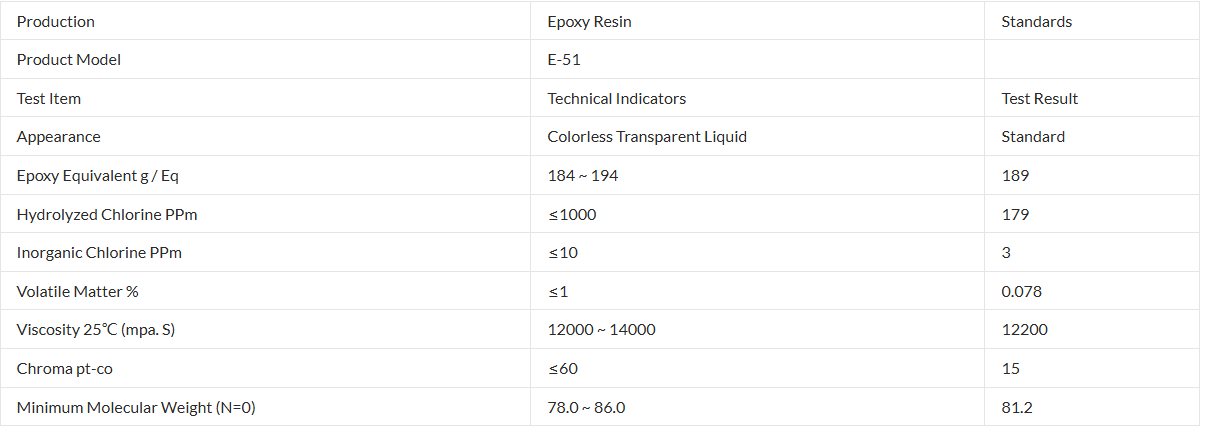

Technical Data for E51

Property and Characteristic

High mechanical properties. Epoxy resin E51 has strong cohesion and dense molecular structure, so its mechanical properties are higher than those of general thermosetting resins such as phenolic resin and unsaturated polyester.

Strong adhesion. The curing system of epoxy resin contains epoxy group, hydroxyl group, ether bond, amine bond, ester bond and other polar groups with great activity, which endows the epoxy cured material with excellent adhesion to polar substrates such as metal, ceramics, glass, concrete and wood.

Good processability: epoxy resin basically does not produce low molecular volatiles when curing, so it can be molded under low pressure or contact pressure. Epoxy resin E44 can be used with various curing agents to manufacture solvent-free, high solid, powder coatings, water-based coatings and other environment-friendly coatings.

Excellent electrical insulation: Epoxy resin is one of the best varieties of thermosetting resin with medium electrical properties.

Good stability and chemical resistance. The epoxy resin without impurities such as alkali and salt is not easy to deteriorate. As long as it is properly stored (sealed, free from moisture and high temperature), the storage period is 1 year. It can still be used if it passes the inspection after expiration. The epoxy curing compound has excellent chemical stability. Its corrosion resistance to alkali, acid, salt and other media is better than that of unsaturated polyester resin, phenolic resin and other thermosetting resins. Therefore, epoxy resin is widely used as anti-corrosion primer. Because the cured epoxy resin has a three-dimensional network structure and is resistant to oil impregnation, it is widely used in the inner wall lining of oil tanks, oil tankers and aircraft.

Storage and Shipping

When storing epoxy resin, please keep away from direct sunlight, heat source, ignition point and waterproof. Dangerous goods shall be stored according to regulations. If they are not used up after opening, they shall be sealed for storage. The shelf life of epoxy resin is generally 1 years, and it can still be used after passing the retest. Under relative conditions, such as storage at freezing temperature, some epoxy resins may crystallize, which is only a physical change and does not change their chemical properties. In case of crystallization, the resin can be heated to 70-80 ° C and restored to its original state by stirring.

Usage

Epoxy resin is rarely used alone. Generally, auxiliary materials such as curing agent filler are used. Tertiary amine compounds are used as curing agents, which are usually 5 to 15% of the resin amount. Acid anhydride is used as curing agent, which is 0.1 to 3% of the resin amount. Polybasic adhesive is used as curing benefit. Epoxy resin is cut to 1:1 mol cal. 703 is used as curing agent, which can be used according to 1.0.4

- Q: I have been considering spending money to buy a fuel additive to increase my mpg and hopefully as an end result help me save money on gas. I am leery to start buying tablets though as it is an added expense in itself. Does anyone have any experience with diesel fuel additives? If so, can you recommend one that works?

- I work in as a fleet mechanic on International trucks. There is no diesel additive on the market that will increase your fuel mileage. There are plenty of additives out there, but nothing that will improve your fuel mileage. If there was, we would be using them in our fleet. The only thing we ever put in our fuel is automatic transmission fluid. We put a quart in the fuel about every third tank because it is high detergent and helps keep the nozzles clean. I am sorry to tell you, the only way to improve your fuel mileage is to change driving habits. This didn't set well with our drivers either.

- Q: Folks, I have a 1994 GCL V8 with the AWD and infamous viscous coupler just replaced both front axles and rebuilt the drive shaft, and the viscous coupler is still binding, grinding and hopping a wheel when hot on turns that are getting less and less tight. The last thing I want to do right now is replace the viscous coupler. Has any used, or is anyone aware of, an additive that would slicken things up in the transfer case and squeak a little more life out of the vc ?? Thanks in advance -

- Could be the transmission - or the torque convertor.

- Q: what is the difference between inverse and additive inverse on rational numbers?

- Hi Inverse most probably refers to the reciprocal of the rational number. Additive inverse is the number, which when added to the original number, gives zero. For example: For 3, inverse is 1/3 and additive inverse is -3.

- Q: Apart from flavor enhancers, what other food additives are addictive?

- Flavor enhancers. Lol. That's is a made up term for msg. It is not addictive and neither is any other food additive unless you've been lacing your pancakes with morphine. What you have been reading is junk science designed to scare you into eating one way or another. Please improve your critical thinking skills to be able to determine such nonsense.

- Q: What are the additives and additives?

- Preservatives are mainly potassium sorbate (or sorbic acid) and sodium benzoate (or benzoic acid), so look at the preservatives to see these two. In addition, potassium sorbate better than sodium benzoate, Oh, in the human body to be more thorough metabolism, the cost should be higher.

- Q: Find the additive and multiplicative inverse of -36.?

- Additive inverse: 36 Multiplicative inverse: -1/36 Right? Come on man, this stuff should be obvious.

- Q: How to sell fuel additives

- What car needs to add fuel additives to understand the role of additives, then it can be said that as long as the car will need to use, especially the import of the engine, although the introduction of the domestic time after a certain tuning, but because the domestic oil quality is not good , There will be adverse conditions of the engine acclimatized, mainly due to fuel is not up to the standard caused.

- Q: According to the European commission, food additives are substances added intentionally to food to perform certain technological functions, like to color, to sweeten or to preserve. Food additives can also do more then that, which can be a bad thing. Though food additives can make food look better and even last longer, food additives can create antibiotic resistance, food allergies and hyperactivity. The worst thing about food additives is that it creates antibiotic resistance in humans. This means it will resist any antibiotic that you will take and many people can become immune to important medicines that could have saved their lives. How all this happens is “Giant agricultural businesses pack together cattle by the hundreds to thousands, necessitating the use of germ-fighting antibiotics that we end up swallowing.” (Hawaleska). This result of their care could affect a lot of people. is this good?

- If this is for a school report,you may want to cite a specific reference or two when it comes to supporting the claim that food additives can eventually create super germs(since you state that they will have antibiotic resistance). If there were any studies done my colleges or hospitals on this. You want to list their findings if it offers some sort of evidence to back up what you're writing.

- Q: GB14880-2009 and GB2760-2017 at the same time apply? GB14880-2009 and GB2760-2017 at the same time apply? Nutritional supplements and food additives in the end what relationship ah? How they and food ingredients to define their food ingredients and how to define it?

- GB2760 listed in the food additives, GB2760 is not listed in the GB14880 is listed in the food fortifier, also listed I am afraid that when the additive treatment is more secure, or suspected of abuse.

- Q: find the additive and multiplicative inverses for 8?

- They are correct; the answers are -8 and 1/8. Jaden's wrong though about getting 0 when you multiply a number by its multiplicative inverse. You get 1. Here's a little more of an explanation: An identity is a number such that, when you {add, multiply, etc} another number to it, you get that number back. The second number keeps its identity. So the additive identity is 0, because 8 + 0 0 + 8 , and the multiplicative identity is 1, because 8 x 1 1 x 8 8. The inverse of a number is a number such that, when you {add, multiply} by the original number, you get the identity number. So the additive inverse of 8 is the number that you would add to 8 in order to get 0 (the identity); that number is -8. The multiplicative inverse of 8 is the number that you would multiply by 8 in order to get 1 (the identity); that number is 1/8.

Send your message to us

Epoxy Resin E51 128 220kgs/Barrel Bisphenol A Liquid Epoxy Resin Building Adhesive

1 - 4 PCS

US$1220

5 - 9 PCS

US$1200

>= 10 PCS

US$1180

- Loading Port:

- Guangzhou

- Delivery Time:

- 20 days after your payment

Option:

- Quantity:

- Shipping:

- Freight Cost Calculator

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products