SAG638 antifoam emulsion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SAG 638 antifoam emulsion is an excellent candidate to consider for general purpose foam control in aqueous systems.

SAG 638 antifoam emulsion excels in applications requiring excellent knock down and durability. Remarkably small concentrations can sharply reduce the foam created, which can cut down the processing time and potentially permit maximum capacity production.

| Key Features and Typical Benefits outstanding and quick foam knockdown excellent durability in both non-ionicand anionic surfactant systems long lasting antifoam performance inacidic and alkaline conditions good emulsion stability readily dispersible in the foaming media

| Potential Applications foam control in textile pre-treatment processes and textile print pastes textile sizing and scouring agents acrylic latexes and thickeners used for textiles and nonwovens other chemicals and chemical processes requiring foam control |

Figure 1: The picture below shows the stability of a 10% aqueous dilution of SAG 638 antifoam emulsion as opposed a comparative antifoam Product A, available in the market.

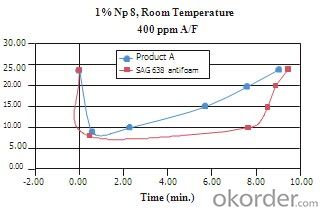

Figure 2: The graph below shows the exceptional foam knockdown ability of SAG 638 antifoam emulsion as compared to competitive antifoam (Product A).

General Instructions for Use

SAG 638 antifoam emulsion can provide excellent performance as a defoamer as well as an antifoam agent. Therefore, it is recommended that SAG 638 antifoam emulsion be added to the aqueous system before the foaming process

starts.

Generally, only a very low concentration of 50 - 100 ppm or 0.05 - 0.1 g/L of SAG 638 antifoam emulsion is necessary to suppress foam. However, the optimum level is really dependent upon many factors such as temperature, bath composition,

viscosity or agitation of the foaming system.

Use SAG 638 antifoam emulsion as received or dilute first with water.

Mix the antifoam well before use.

Dilution: Mix 3 to 10 parts of water to 1 part antifoam emulsion and stir gently until a uniform mixture is obtained. For a long-

term bulk stability of the dilution, thickener and biocides need to be added.

Dilution of Sag 638 antifoam emulsion to 15% solids

- Q: How to use food additives properly

- Potassium sorbate is colorless to white scaly crystalline or crystalline powder, odorless or slightly odorous, unstable in the air, can be oxidized and colored, has a very weak toxicity to humans, but it is an unsaturated Fatty acids (salts), can be absorbed by the body's metabolic system and quickly decomposed into carbon dioxide and water, no residue in the body.

- Q: What is the country that allows the addition of liquor food additives (flavors)

- First look at the color of the food is correct, such as carrots, depends on the color is not bright red; cabbage, depends on the color is not green. This is the first point.

- Q: Hi, has anyone used Lucas oil stabilizer in there car or truck? If so what for and what differences did you hear/feel? Thanx

- Dont use the stuff, it aerates the oil, may potentially wreck your engine. Good quality engine oil is all you need, its what the car engineers spent millions of dollars designing the engine to use. If you want to use thicker oil use thicker oil without some questionable additive.

- Q: As in the fuel treatment/cleaners made by stp and brands like that?And does anyone who has experience using them actually see a performance boost?

- it never harmed my engine and i used it a lot.

- Q: I‘m doing a project on Food Additives, and I‘m confused regarding milk and water. Milk is used in its various processed forms such as milk powder, milk essence, low-sodium milk, lactose free milk, etc., and water is also now available as flavored water, sparkling water, etc., which can be used in various recipes. (Any recipes using flavored water??) So are milk and water food additives or not? What are the various other forms by which milk and water can be used for food processing?

- In their natural state, they are not additives. I usually think of additives as chemical or unnatural ingredients such as MSG.

- Q: Are they required by law to ensure that whatever is written on the label is in fact true? I recall an incident in Australia where a group of high school kids performed their own analysis of Ribena Blackcurrent Juice (Who market there product with the slogan Contains more Vitamin C than oranges They found that Ribena actually had next to no Vitamin C content. So I wonder, is this just ONE product that has been found out?If the jars of food I buy for my baby list the only ingredients as say eg. Pumpkin, Sweet Corn and Water (added during cooking to ensure appropriate texture) and that it contains no additives, flavours, thickeners, added sugar or salt and is gluten freeHow do we know they're not just sayng that?!?!FYII mostly always home cook for my baby unless we are out which is rarely!! and then I feed him baby food :)

- I was just researching this tonight. What I read was that they are all very similar for the stage one foods. Stage 2 and 3, Gerber is actually one of the worst. Growing up Healthy was the best, but that is hard to find. Beech Nut was also pretty good. However, Beech Nut also has some foods with fillers. I'm just going to try and make my own baby food. That way I KNOW what is in there.

- Q: Car had had oil change a 1000 miles ago and was not scheduled for change for anothr2 thousand we have routine maintenance done 1998 ford escort LX 271,000 Ford did a 75 dollar full diagnostics check and told us it needed a tune up.sears was cheaper.we went and got it done.sears said they added some type of additive [[Ford found no problems before with engine just needed tune up and brake work front brakes brand new now]] car had a new weird vibartion to it after sears did tune upthey said they added some type of additive didn‘t say much else other then get a full tank of gas in it to help. Car broke down after driving less then a quarter of a mile.did they accidentally put oil in? did they put something in the oil which caused it? The ford place has it and quoute on quote said what the heck did sears do there is oil overflowed Please help

- its sears what you expect thats where all the joke mechanics work they beat on the car's while bringing em in and **** THERE IS NO REASON TO NEED TO PUT A FUEL ADDITIVE IN AT ALL WHATSO EVER

- Q: Are additives really.?are additives really necessary.do you think they are good or bad for our bodies explain why you think that thanks guys im just wondering :) thanks for all those who answer :D

- The Statue of Liberty

- Q: I know that UV additives for topical wood treatments exist, but I would like to know it the formulas are specific to product formula and how to source this stuff in quantity. Any and all insights are welcome.

- Yes it does, but it's not much. 3-10 hp depending on application. And it's only efficient to have 2 intakes if you have a V configuration. If you don't know what I'm talking about, STOP what you are doing to your car, and read some books about the basics of the internal combustion engine.

- Q: This may have been asked once before, but I‘m asking specifically:Does anyone have any first hand experience with 100% pure acetone as a fuel additive?What are the results?How long have you been using it?Are there any negative side effects?Please do not cite or refer to other websites; I have done my fair share of research and am looking for an opinion from someone who has been using 100% pure acetone. Thank you.

- Yes. All tires have heavy and light spots which is why they need balancing. Weight is added to the wheel opposite the heavy spot. Since you can never get the tire back on the same way and since no two tires are the same it will require a balance job every time the tires are changed.

Send your message to us

SAG638 antifoam emulsion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches